Pre-dispersed masterbatch formula and preparation method thereof

A technology for pre-dispersed master batches and formulations, applied in the field of rubber additives and their preparation, can solve the problems of harming the health of employees, harming the health of operators, easy to agglomerate and difficult to disperse, etc. It can solve the problems of large measurement error and fast vulcanization speed , the effect of simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Described preparation method comprises the steps:

[0023] Step 1. Accurately weigh the raw materials required for the rubber carrier according to the weight ratio of EPDM rubber, EPDM rubber and stearic acid in the range of 8 to 11:1 to 5:1. Rubber and binary ethylene propylene rubber are put into an internal mixer for mixing, and then stearic acid is added for mixing. On the open mill, a sheet-shaped rubber carrier with a thickness of 2 to 20 mm is made.

[0024] Step 2. Accurately weigh each raw material required for the rubber vulcanizing agent according to the proportion; put each raw material into an internal mixer, and mix for 2-10 minutes at a temperature of 80-85° C. and a rotational speed of 55-60 rpm to obtain a rubber compound.

[0025] Step 3. Put the rubber material obtained in step (2) into the extruder, control the given speed of the main engine to be 115-125r / min, and finally extrude to obtain tetrahydro-2(1H)-pyrimidinethione pre-dispersed masterbatch ...

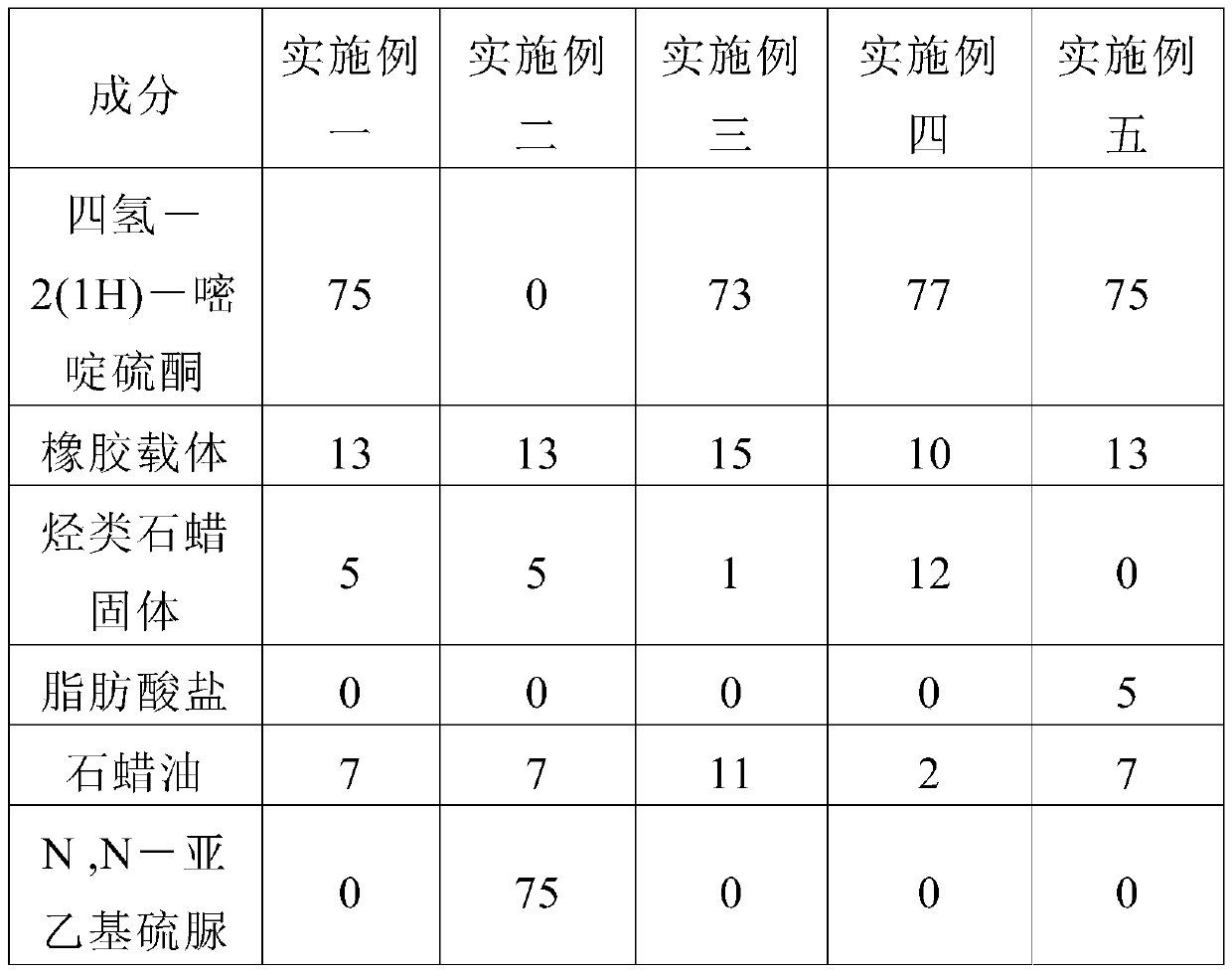

Embodiment 1

[0030] The preparation method of embodiment one, embodiment two and embodiment five is consistent, comprises the steps:

[0031] Step 1. Accurately weigh the raw materials required for the rubber carrier according to the weight ratio of EPDM rubber, binary ethylene propylene rubber and stearic acid of 10:3:1, first mix EPDM rubber, binary ethylene propylene rubber, The ethylene-propylene rubber is put into the internal mixer for mixing, and then stearic acid is added for mixing. On the open mill, a sheet rubber carrier with a thickness of 3mm is made.

[0032] Step 2. Accurately weigh each raw material required for the rubber vulcanizing agent according to the proportion; put each raw material into an internal mixer, and mix for 10 minutes at a temperature of 80° C. and a rotational speed of 60 rpm to obtain a rubber compound.

[0033] Step 3. Put the rubber material obtained in step (2) into an extruder, control the given speed of the main engine to be 120r / min, and extrude a...

Embodiment 3

[0034] The preparation method of embodiment three, comprises the steps:

[0035] Step 1. Accurately weigh the raw materials required for the rubber carrier according to the weight ratio of EPDM rubber, binary ethylene propylene rubber and stearic acid of 8:5:1, first mix EPDM rubber, binary ethylene propylene rubber, Ethylene-propylene rubber is put into a banbury mixer for mixing, and then stearic acid is added for mixing. On the open mill, a sheet-shaped rubber carrier with a thickness of 10mm is made.

[0036] Step 2. Accurately weigh each raw material required for the rubber vulcanizing agent according to the proportion; put each raw material into an internal mixer, and mix for 2 minutes at a temperature of 80° C. and a rotational speed of 55 rpm to obtain a rubber compound.

[0037] Step 3. Put the rubber material obtained in step (2) into an extruder, control the given rotation speed of the main engine to be 115 r / min, and extrude at a temperature of 50° C. to obtain pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com