Solution-Based Growth Method of Cesium Iodide Single Crystal Flakes

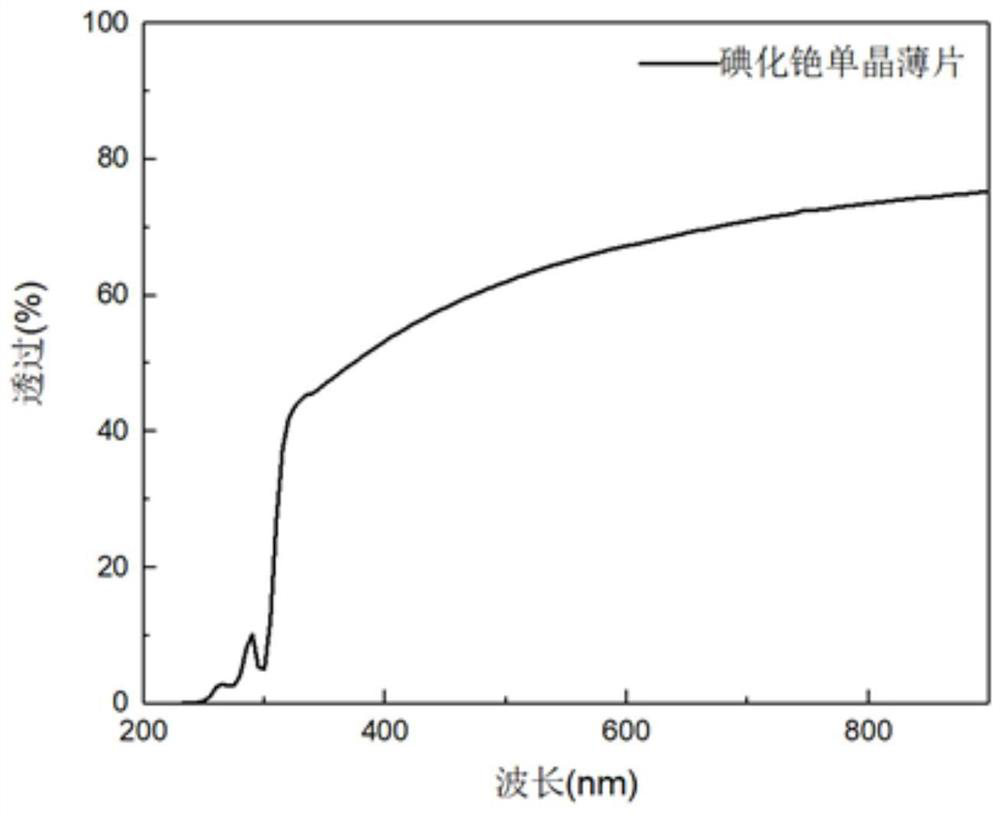

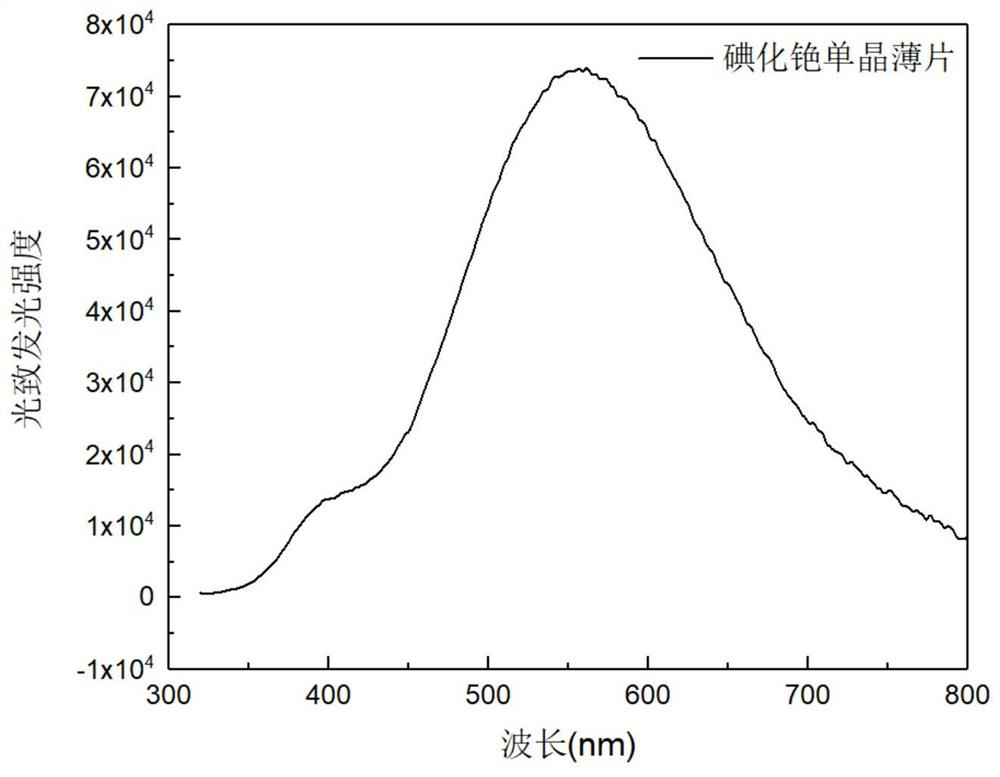

A technology of cesium iodide and flakes, which is applied in the field of crystal material manufacturing, can solve the problems of unsatisfactory light transmittance and light extraction efficiency of cesium iodide single crystals, complex preparation methods, and difficulty in mass production, and achieve excellent light output efficiency and light transmission efficiency. The effect of excellent precision and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

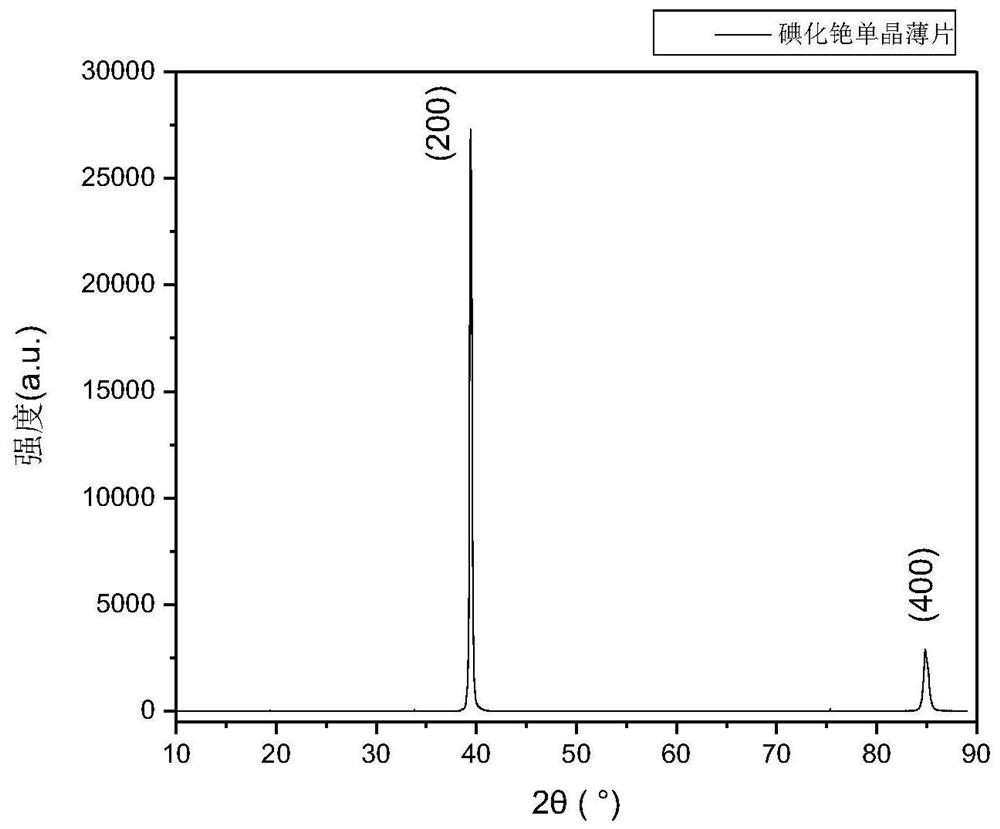

[0027] In this example, participating in Figure 1 ~ Figure 3 , a method for growing a cesium iodide single crystal sheet based on a solution, comprising the steps of:

[0028] a. With dimethyl sulfoxide as solvent, 20ml of dimethyl sulfoxide is added into a flat-bottomed flask, then 10.4g of cesium iodide crystal powder with a purity of 99.9% is added, and the flat-bottomed flask is stirred on a magnetic stirrer, Control the rotation speed to 500r / min, and stir for 12 hours to completely dissolve the cesium iodide crystal powder in dimethyl sulfoxide until saturated and until the solution is clear and transparent; after the cesium iodide crystal powder is fully dissolved, use a The filter tip of micron is filtered, obtains the cesium iodide solution of the long crystal of saturation, for subsequent use;

[0029] b. the saturated crystal-growing cesium iodide solution prepared in the step a is taken out in two parts, and 0.6ml is taken out into a radius of 2cm brown vial A an...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, especially in that:

[0036] In this embodiment, a method for growing a cesium iodide single crystal sheet based on a solution comprises the following steps:

[0037] a. With dimethyl sulfoxide as solvent, 60ml of dimethyl sulfoxide is added into a flat-bottomed flask, then 31.2g of cesium iodide crystal powder with a purity of 99.9% is added, and the flat-bottomed flask is placed on a magnetic stirrer to stir, Control the rotation speed to 700r / min, and stir for 4 hours to completely dissolve the cesium iodide crystal powder in dimethyl sulfoxide until saturated and until the solution is clear and transparent; after the cesium iodide crystal powder is fully dissolved, use a The filter tip of micron is filtered, obtains the cesium iodide solution of the long crystal of saturation, for subsequent use;

[0038] b. the saturated crystal-growing cesium iodide solution prepared in the step a is taken out in two parts, a...

Embodiment 3

[0043] This embodiment is basically the same as the previous embodiment, and the special features are:

[0044] In this embodiment, a method for growing a cesium iodide single crystal sheet based on a solution comprises the following steps:

[0045] a. With dimethyl sulfoxide as solvent, 20ml of dimethyl sulfoxide is added into a flat-bottomed flask, then 10.4g of cesium iodide crystal powder with a purity of 99.9% is added, and the flat-bottomed flask is stirred on a magnetic stirrer, Control the rotation speed to 300r / min, and stir for 4 hours to completely dissolve the cesium iodide crystal powder in dimethyl sulfoxide until saturated and until the solution is clear and transparent; after the cesium iodide crystal powder is fully dissolved, use a The filter tip of micron is filtered, obtains the cesium iodide solution of the long crystal of saturation, for subsequent use;

[0046] b. the saturated crystal-growing cesium iodide solution prepared in the step a is taken out i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com