Preparation method of agricultural and forestry waste adsorbing material for treatment of printing and dyeing wastewater

A technology of agricultural and forestry waste and adsorption materials, which is applied in the field of preparation of agricultural and forestry waste adsorption materials for printing and dyeing wastewater treatment, can solve the problems of destroying human health, organic mutation, and causing cancer, and achieve good flocculation and complexation adsorption. Low rate, safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

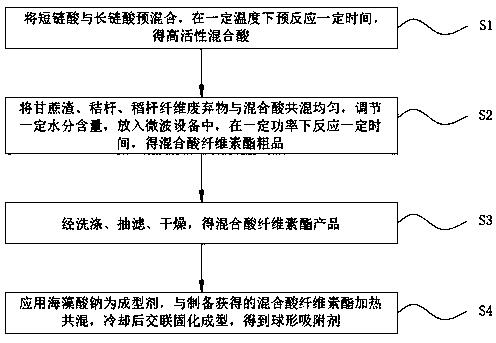

[0022] Embodiment 1: as figure 1 As shown, the present invention provides a technical solution, a method for preparing an agricultural and forestry waste adsorption material for printing and dyeing wastewater treatment, comprising the following steps:

[0023] S1. Premix the short-chain acid and the long-chain acid, and pre-react at a certain temperature for a certain period of time to obtain a highly active mixed acid;

[0024] S2. Blend bagasse, straw, rice straw fiber waste and mixed acid evenly, adjust a certain moisture content, put it into a microwave device, react at a certain power for a certain period of time, and obtain a crude mixed acid cellulose ester;

[0025] S3, after washing, suction filtration and drying, a mixed acid cellulose ester product is obtained;

[0026] S4. Using sodium alginate as a forming agent, heating and blending with the prepared mixed acid cellulose ester, cooling and then crosslinking and solidifying to obtain a spherical adsorbent.

[00...

Embodiment 2

[0034] Embodiment 2: as figure 1 As shown, the present invention provides a technical solution, a method for preparing an agricultural and forestry waste adsorption material for printing and dyeing wastewater treatment, comprising the following steps:

[0035] S1. Premix the short-chain acid and the long-chain acid, and pre-react at a certain temperature for a certain period of time to obtain a highly active mixed acid;

[0036] S2. Blend bagasse, straw, rice straw fiber waste and mixed acid evenly, adjust a certain moisture content, put it into a microwave device, react at a certain power for a certain period of time, and obtain a crude mixed acid cellulose ester;

[0037] S3, after washing, suction filtration and drying, a mixed acid cellulose ester product is obtained;

[0038] S4. Using sodium alginate as a forming agent, heating and blending with the prepared mixed acid cellulose ester, cooling and then crosslinking and solidifying to obtain a spherical adsorbent.

[00...

Embodiment 3

[0046] Embodiment 3: as figure 1 As shown, the present invention provides a technical solution, a method for preparing an agricultural and forestry waste adsorption material for printing and dyeing wastewater treatment, comprising the following steps:

[0047] S1. Premix the short-chain acid and the long-chain acid, and pre-react at a certain temperature for a certain period of time to obtain a highly active mixed acid;

[0048] S2. Blend bagasse, straw, rice straw fiber waste and mixed acid evenly, adjust a certain moisture content, put it into a microwave device, react at a certain power for a certain period of time, and obtain a crude mixed acid cellulose ester;

[0049] S3, after washing, suction filtration and drying, a mixed acid cellulose ester product is obtained;

[0050] S4. Using sodium alginate as a forming agent, heating and blending with the prepared mixed acid cellulose ester, cooling and then crosslinking and solidifying to obtain a spherical adsorbent.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com