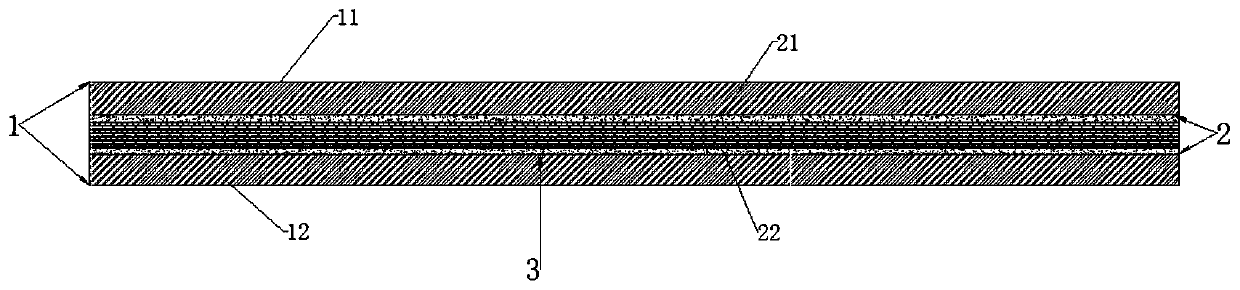

Nanofiber multi-component compound silky non-woven fabric and manufacturing method thereof

A technology of nanofibers and non-woven fabrics, applied in the direction of non-woven fabrics, rayon manufacturing, fiber treatment, etc., to achieve the effects of enhanced softness, good mechanical properties, and excellent photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

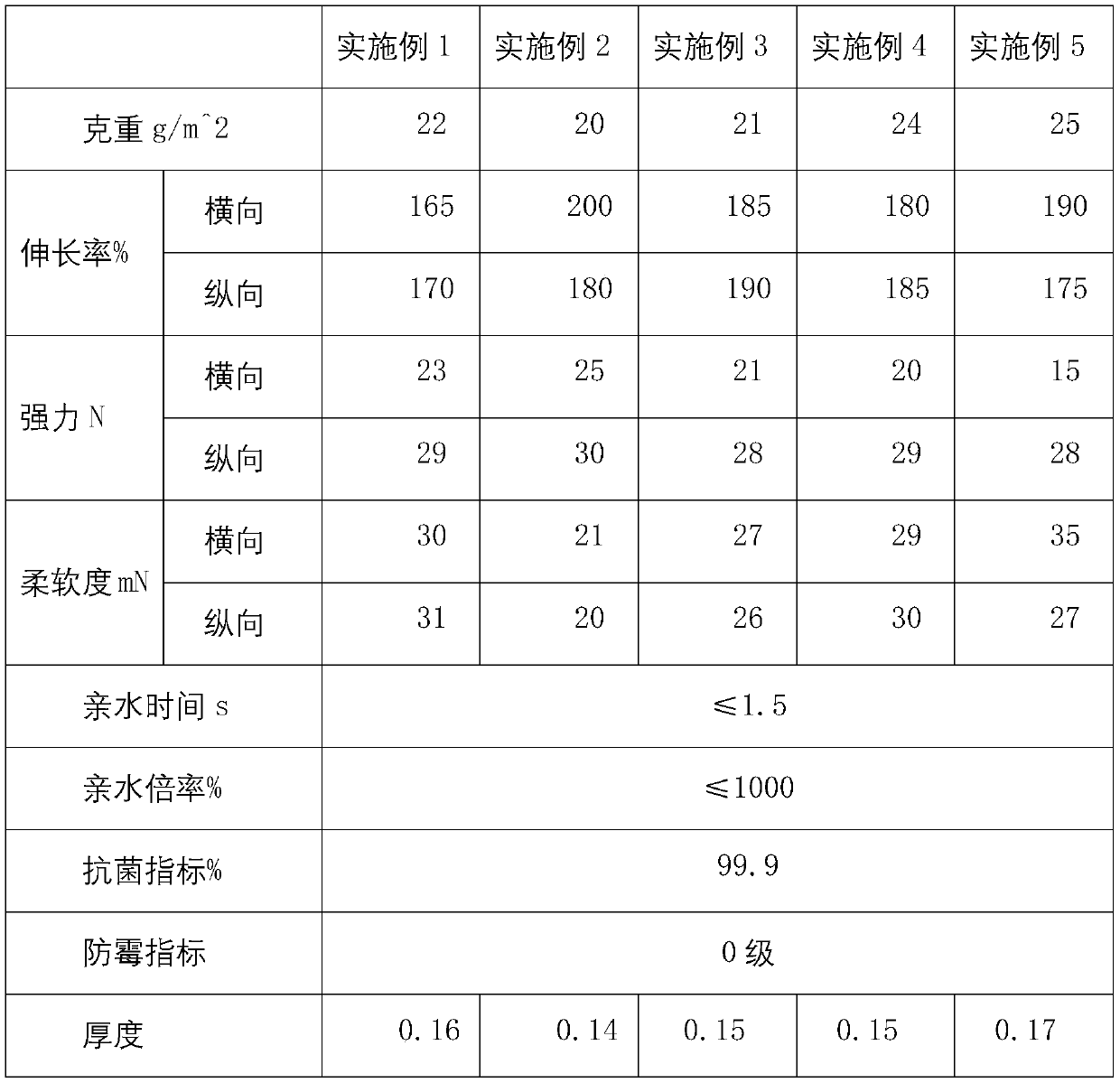

Embodiment 1

[0045] Preparation of nano silk soft layer:

[0046] (1) The elastomer mixture is composed of the following components in parts by mass: 80 parts of nanoscale elastomer particles, 10 parts of flexible masterbatch, 5 parts of blending agent, and 5 parts of polypropylene; The granules are heated by thermal radiation, and heated to a state of fluid but not liquefied; then, add soft masterbatch, blending agent, polypropylene, and keep the temperature constant, and stir evenly to obtain a mixture; finally, the mixture cooling to obtain the elastomer mixture;

[0047] (2) The nano-modified silk fiber is composed of the following components in parts by mass: 65 parts of polypropylene masterbatch, 25 parts of polyester, 10 parts of elastomer mixture, TiO 2 5 parts of nano-powder; the above-mentioned polypropylene masterbatch and polyester are respectively heated and melted and plasticized by a screw extruder; after passing through the screw extruder, add the elastomer mixture, TiO 2...

Embodiment 2

[0058] Preparation of nano silk soft layer:

[0059] (1) The elastomer mixture is composed of the following components in parts by mass: 85 parts of nanoscale elastomer particles, 8 parts of flexible masterbatch, 2 parts of blending agent, and 5 parts of polypropylene; The granules are heated by thermal radiation, and heated to a state of fluid but not liquefied; then, add soft masterbatch, blending agent, polypropylene, and keep the temperature constant, and stir evenly to obtain a mixture; finally, the mixture cooling to obtain the elastomer mixture;

[0060] (2) The nano-modified silk fiber is composed of the following components in parts by mass: 60 parts of polypropylene masterbatch, 25 parts of polyester, 5 parts of elastomer mixture, TiO 2 5 parts of nano-powder; the above-mentioned polypropylene masterbatch and polyester are respectively heated and melted and plasticized by a screw extruder; after passing through the screw extruder, add the elastomer mixture, TiO 2 nan...

Embodiment 3

[0071] Preparation of nano silk soft layer:

[0072] (1) The elastomer mixture is composed of the following components in parts by mass: 78 parts of nanoscale elastomer particles, 10 parts of flexible masterbatch, 5 parts of blending agent, and 5 parts of polypropylene; The granules are heated by thermal radiation, and heated to a state of fluid but not liquefied; then, add soft masterbatch, blending agent, polypropylene, and keep the temperature constant, and stir evenly to obtain a mixture; finally, the mixture cooling to obtain the elastomer mixture;

[0073] (2) The nano-modified silk fiber is composed of the following components in parts by mass: 62 parts of polypropylene masterbatch, 28 parts of polyester, 5 parts of elastomer mixture, TiO 2 5 parts of nano-powder; the above-mentioned polypropylene masterbatch and polyester are respectively heated and melted and plasticized by a screw extruder; after passing through the screw extruder, add the elastomer mixture, TiO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com