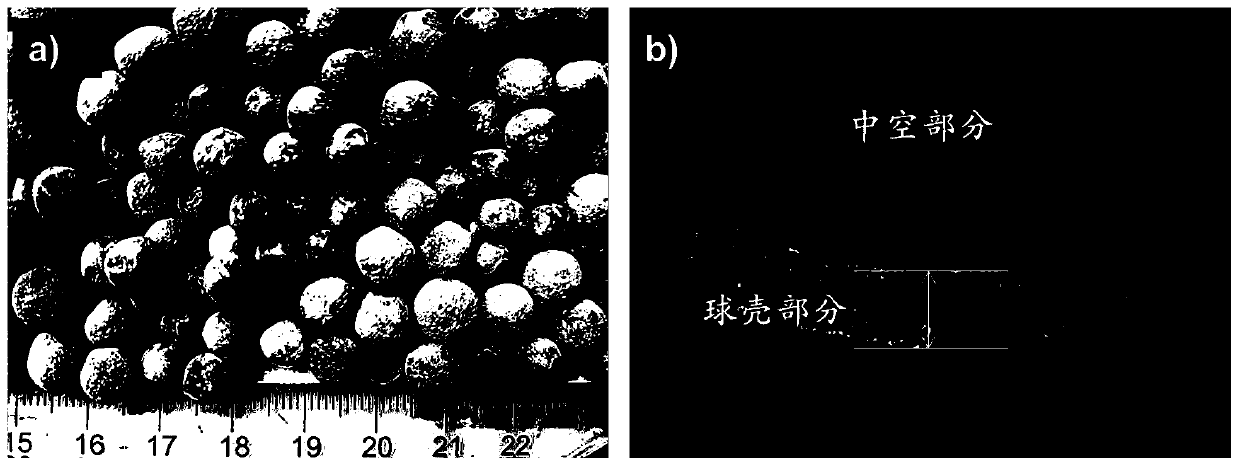

Reusable large-size hollow adsorbent and preparation method and application thereof

A hollow, adsorbent technology, applied in the direction of selective adsorption, separation methods, chemical instruments and methods, etc., can solve the problems of low yield, uneven shrinkage, easy cracking, etc., and achieve good effect, significant environmental protection effect, oil absorption efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of a hollow adsorbent with a particle size of 8-10mm and a hollow aperture of 3-5mm of the present embodiment is as follows:

[0043] (1) Weigh 1kg of ordinary Portland cement and dry it at about 100°C, and make the powder all pass through a 200-mesh sieve for later use;

[0044] (2) Weigh 500g of urea pellets (particle size 3-5mm), and add it into the pelletizer; start the pelletizer, take the aqueous solution of 0.5wt% CMC as a binder, and spray it on the urea particle surface;

[0045] (3) Gradually add the above-mentioned dried and sieved cement powder, repeat the steps of spraying the binder and adding the cement powder, until the ball diameter of most of the samples reaches 8mm, and screen out the particles of 8-10mm using a mesh screen ;

[0046] (4) carrying out standard curing for the above-mentioned obtained samples in a standard curing box for 24h;

[0047] (5) Immerse the cured sample particles in water, rinse the urea cores complet...

Embodiment 2

[0049] The preparation method of a hollow adsorbent with a particle size of 5-8 mm and a hollow aperture of 2-3 mm of the present embodiment is as follows:

[0050] (1) take 1kg of gypsum powder and dry it at about 100°C, and make the powder all pass through a 200-mesh sieve for later use;

[0051] (2) Weigh 500g of compound fertilizer pellets (particle size 2-3mm), and add it into the pelletizer; start the pelletizer, use the aqueous solution of 0.5wt% guar gum as the binder, and put the pellets into the pelletizer. It is sprayed on the surface of urea particles;

[0052] (3) Gradually add the above-mentioned gypsum powder after drying and sieving, repeat the steps of spraying the binder and adding cement powder, until the ball diameter of most of the samples reaches 5mm, use a mesh screen to screen out particles of 5-8mm ;

[0053] (4) carrying out standard curing for the above-mentioned obtained samples in a standard curing box for 24h;

[0054] (5) Soak the cured sample...

Embodiment 3

[0056] The preparation method of a hollow adsorbent with a particle size of 8-10mm and a hollow aperture of 3-5mm of the present embodiment is as follows:

[0057] (1) Weigh 1kg of ordinary Portland cement and dry it at about 100°C, and make the powder all pass through a 200-mesh sieve for later use;

[0058] (2) Weigh 20g of polystyrene pellets (particle size 3-5mm), and add them into the pelletizer; start the pelletizer, use the aqueous solution of 1.0wt% polyvinyl alcohol as the binder, and put the pellets into the pelletizer. It is sprayed on the surface of polystyrene particles;

[0059] (3) Gradually add the above-mentioned dried and sieved cement powder, repeat the steps of spraying the binder and adding the cement powder, until the ball diameter of most of the samples reaches 8mm, and screen out the particles of 8-10mm using a mesh screen ;

[0060] (4) carrying out standard curing for the above-mentioned obtained samples in a standard curing box for 24h;

[0061] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com