Laser-electric arc compound welding method suitable for high strength aluminum alloy downward welding

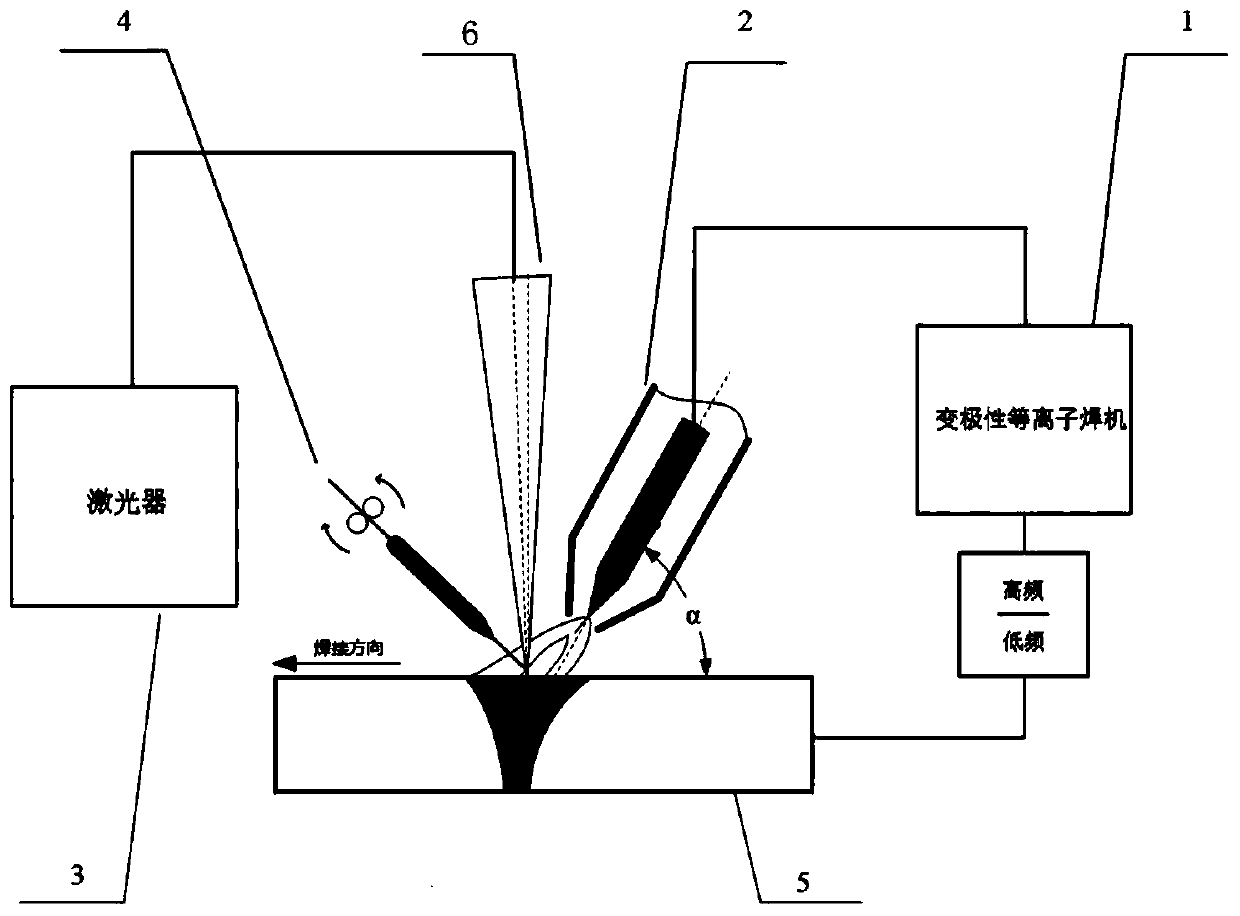

A compound welding and aluminum alloy technology, which is applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of non-compressed arc divergence, joint strength reduction, and large fluctuation of reinforcement, so as to improve joint softening , Welding efficiency improvement, welding quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

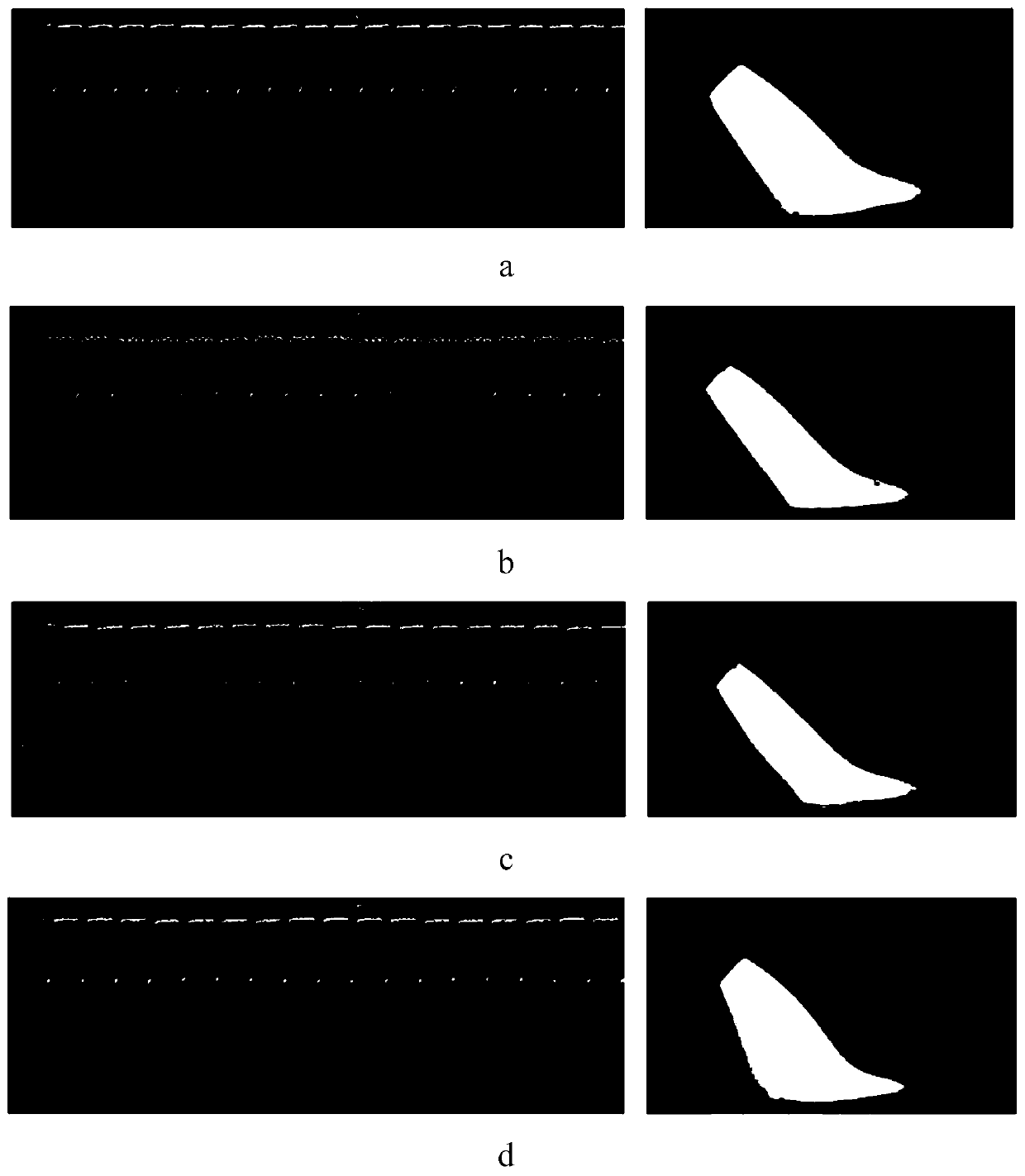

[0037] The laser-polarity variable plasma arc composite welding method is used to weld 6mm thick 7075 aluminum alloy. The welding parameters are fiber laser power 1.55kW, variable polarity plasma arc positive polarity current 155A, reverse polarity current 190A, positive and negative polarity time ratio 21 : 4. The welding speed is 900mm / min, and the wire feeding speed is 6m / min; before welding, clean the workpiece to be welded. The cleaning method adopts mechanical grinding, and then fix the workpiece on the workbench with a fixture. Laser-polarity variable plasma arc hybrid welding test, while collecting the shape of the variable polarity plasma arc and arc electric signal, the collected signals are as follows: image 3 as shown in a.

Embodiment 2

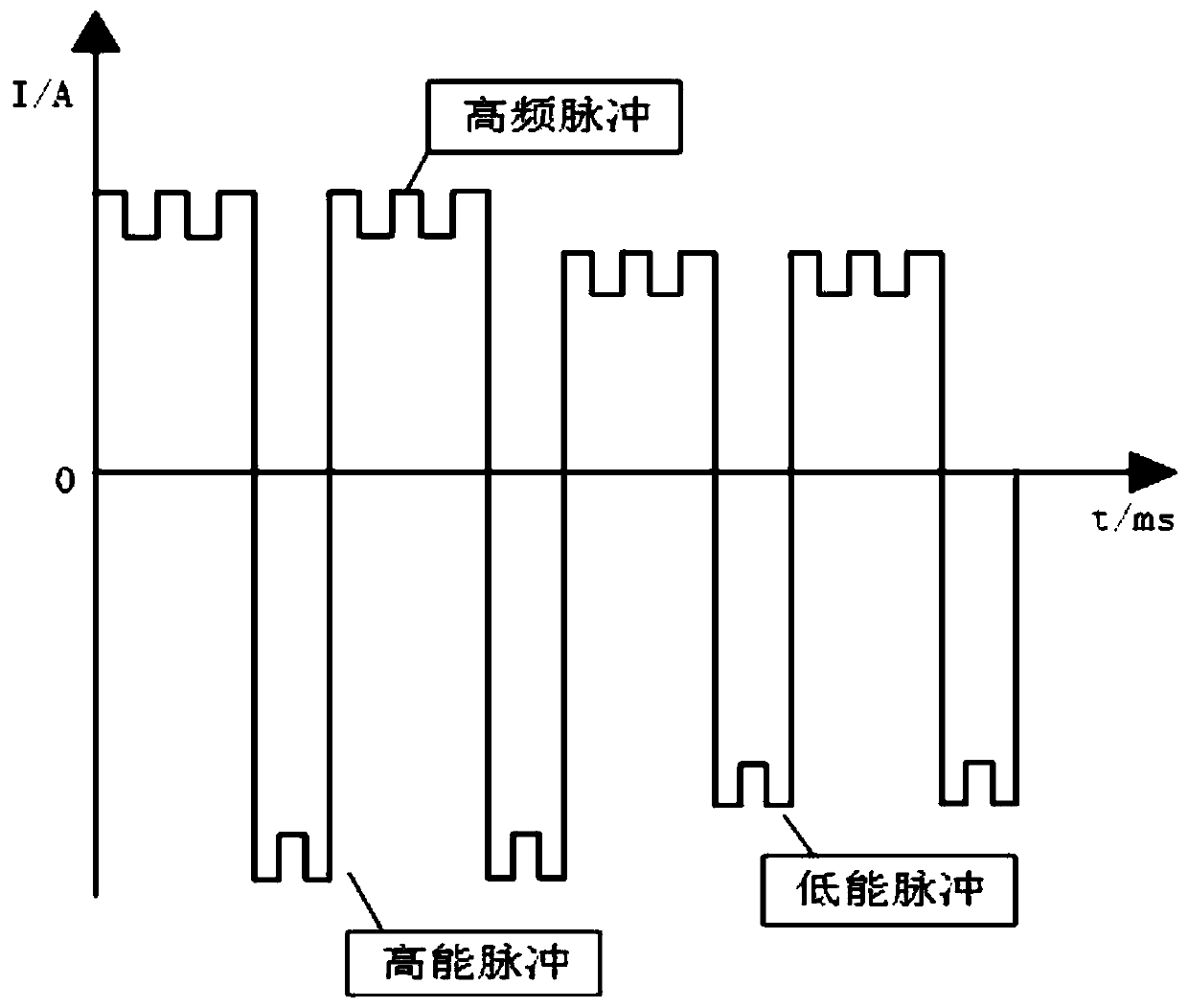

[0039] Implant 200Hz high-frequency pulses into the variable polarity plasma arc, and conduct laser-double pulse variable polarity plasma arc composite welding test. The welding parameters are fiber laser power 1.55kW, variable polarity plasma arc positive polarity current 155A, reverse polarity current 190A, positive and negative polarity time ratio 21:4, welding speed 900mm / min, wire feeding speed 6m / min; before welding, clean the workpiece to be welded, the cleaning method is mechanical grinding, and then fix the workpiece on the workbench with a fixture Above, after the welding trajectory test is completed, the laser-pulse variable polarity plasma arc composite welding test is carried out on the 6mm thick 7075 aluminum alloy, and the shape of the variable polarity plasma arc and the electric arc signal are collected at the same time. The collected signals are as follows: image 3 as shown in b.

Embodiment 3

[0041] A 500Hz high-frequency pulse was implanted into the variable polarity plasma arc, and the laser-double pulse variable polarity plasma arc composite welding test was carried out. The welding parameters were fiber laser power 1.55kW, variable polarity plasma arc positive polarity current 155A, and reverse polarity current 190A, positive and negative polarity time ratio 21:4, welding speed 900mm / min, wire feeding speed 6m / min; before welding, clean the workpiece to be welded, the cleaning method is mechanical grinding, and then fix the workpiece on the workbench with a fixture Above, after the welding trajectory test is completed, the laser-pulse variable polarity plasma arc composite welding test is carried out on the 6mm thick 7075 aluminum alloy, and the shape of the variable polarity plasma arc and the electric arc signal are collected at the same time. The collected signals are as follows: image 3 as shown in c. The weld is formed as Figure 4 As shown, the weld sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com