Preparation method of modified starch ether for prolonging opening time of ceramic tile glue

An open time, starch ether technology, applied in the direction of adhesive additives, polymer adhesive additives, etc., can solve problems such as unfavorable industrial production, complicated operation, etc., to improve strength and bonding performance, expand market space, and prolong opening. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

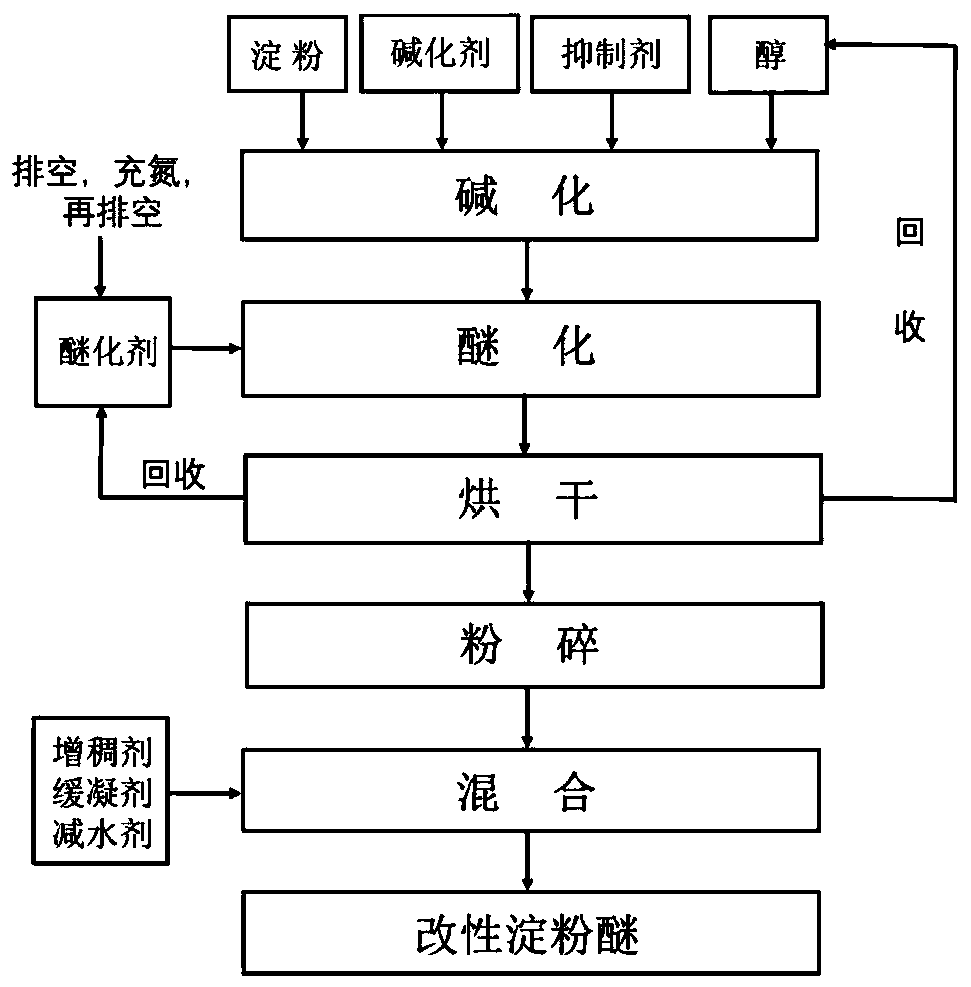

[0043] A kind of preparation method of the modified starch ether that promotes tile glue open time, comprises the following operation steps:

[0044] (1) Chemical modification: etherification, drying and crushing of starch

[0045] Add starch, basifying agent, alcohol and inhibitor successively to the stirred reactor with jacket, empty the reactor and purging with nitrogen to remove oxygen, empty again, then add etherification agent in the reactor, heat up, After the reaction is finished, dry and recover the alcohol, and pulverize;

[0046] The starch is tapioca starch; the alkalizing agent is NaOH; the alcohol is ethanol; the inhibitor is Na 2 SO 4 ; The etherifying agent is chloroacetic acid, propylene oxide and oxyethane;

[0047] The reaction conditions for the etherification are 1.5 hours at 20°C, 2.5 hours at 40°C, and 4 hours at 60°C;

[0048] The mass ratio of starch, sodium hydroxide, chloroacetic acid, propylene oxide and ethylene oxide is =1:0.09:0.10:0.18:0.02;...

Embodiment 2

[0071] A kind of preparation method of the modified starch ether that promotes tile glue open time, comprises the following operation steps:

[0072] (1) prepare another kind of starch ether of the present invention according to the description of embodiment 1 step (1), the difference is that the etherification agent is chloroacetic acid and propylene oxide, starch, sodium hydroxide, chloroacetic acid and cyclic The mass ratio of oxypropane is =1:0.09:0.10:0.18, and the reaction temperature of etherification is 2 hours at 35°C, 3 hours at 50°C, and 4 hours at 65°C;

[0073] The carboxymethyl substitution degree in the obtained carboxymethyl hydroxypropyl starch is 0.16, the hydroxypropoxy content is 16.5%, the 5% viscosity is 7000cp, and the ash content is 16%;

[0074] (2) Physical modification: mix the starch ether, thickener, retarder and water reducer prepared in (1)

[0075] Add carboxymethyl hydroxypropyl starch, thickener, retarder and water reducer into a mixer and mi...

Embodiment 3

[0094] A kind of preparation method of the modified starch ether that promotes tile glue open time, comprises the following steps:

[0095] (1) prepare another kind of starch ether of the present invention according to the description of embodiment 1 step (1), the difference is that the etherifying agent is propylene oxide and ethylene oxide, starch, sodium hydroxide, epoxy The mass ratio of propane to ethylene oxide is =1:0.02:0.30:0.02, and the etherification reaction temperature is 30°C for 2 hours, 50°C for 4 hours, and 70°C for 4 hours;

[0096] The hydroxypropoxyl content in the prepared 1# hydroxypropyl hydroxyethyl starch is 25.0%, the hydroxyethoxyl content is 2.5%, the 5% viscosity is 9000cp, and the ash content is 8%;

[0097] (2) Physical modification: Mix the starch ether, thickener, retarder and water reducer in (1).

[0098] Add 1# hydroxypropyl hydroxyethyl starch, thickener, retarder and water reducing agent into the mixer and mix for 40-60 minutes to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com