Heavy metal pollution stabilized repair material suitable for tailings and waste rock and preparation method of heavy metal pollution stabilized repair material

A technology for repairing materials and heavy metals, applied in chemical instruments and methods, soil conditioning materials, applications, etc., can solve the problems of aggravating acid waste water from waste ores, unable to block acid waste water, and high capital investment, so as to improve environmental adaptability and effective Conducive to high-efficiency reproduction and the effect of improving control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with specific embodiment:

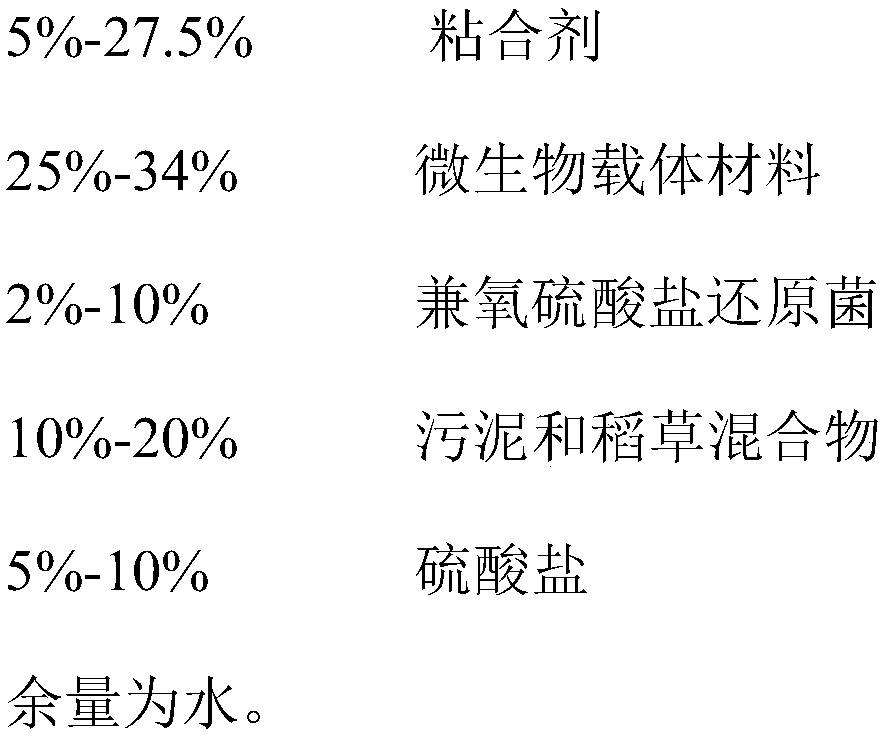

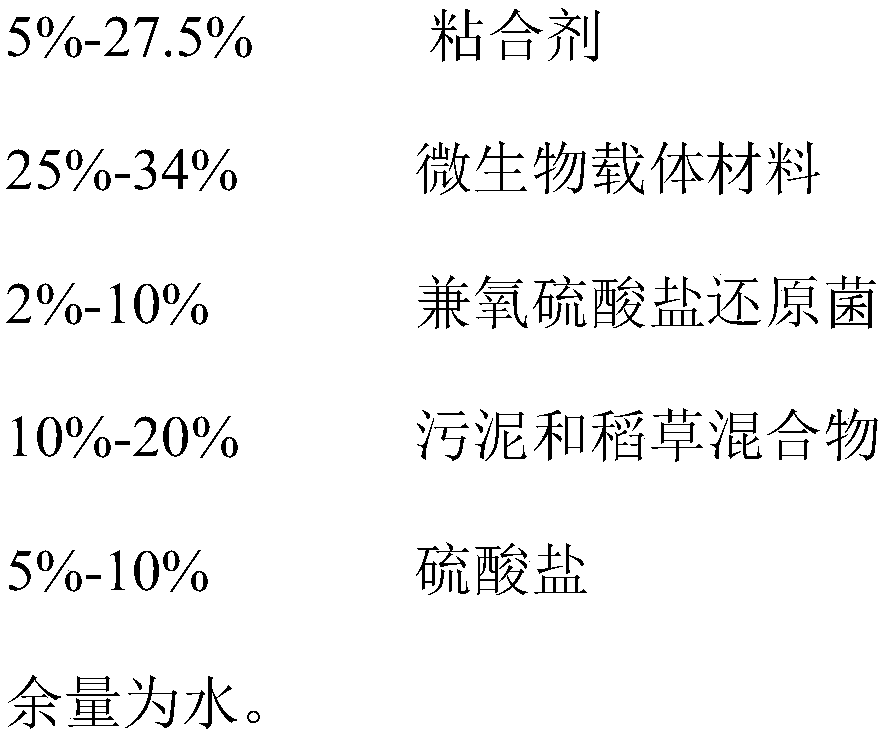

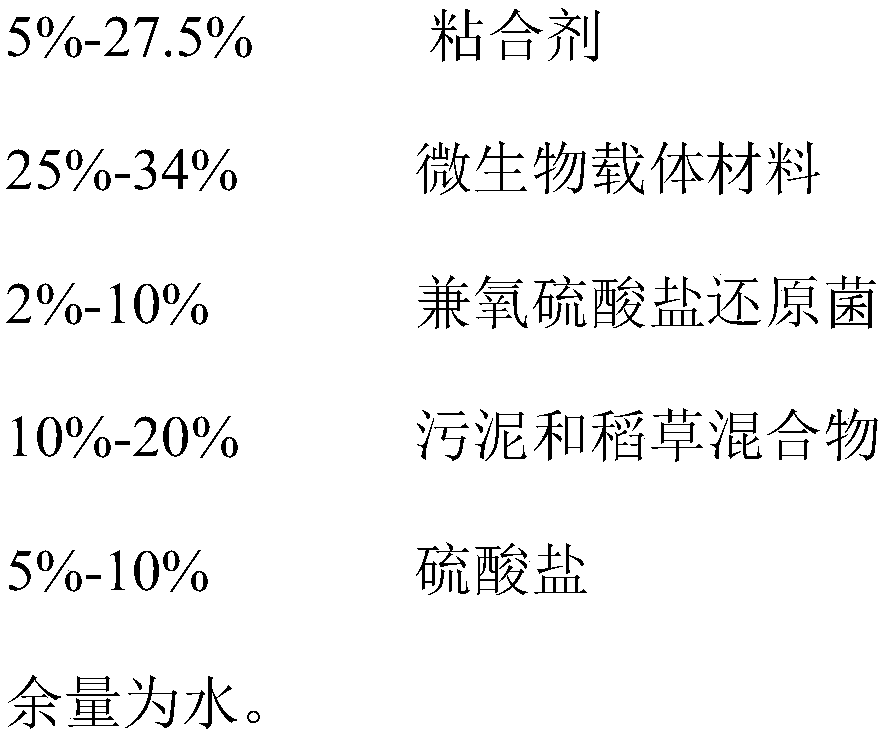

[0026] A repairing material suitable for stabilizing tailings and waste rock heavy metal pollution. In terms of mass percentage, the repairing material includes the following components:

[0027]

[0028] The mass ratio of cement, fine sand and maltodextrin in the binder is 0.5-1:0.3:0.8-1.

[0029] The microbial carrier materials include zeolite and hydrothermal carbon.

[0030] The restorative material is in the form of microsphere particles with a particle diameter of 0.5 mm to 2 mm.

[0031] A method for preparing a repair material suitable for stabilizing tailings waste rock heavy metal pollution, the preparation method of the repair material includes the following steps:

[0032] (1) Add zeolite to glucose to form a zeolite-glucose mixture with a concentration of 40-50g / L, and then perform ultrasonic uniform dispersion, hydrothermal reaction, and filtration to obtain s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com