Making method of cuttlefish ink bread

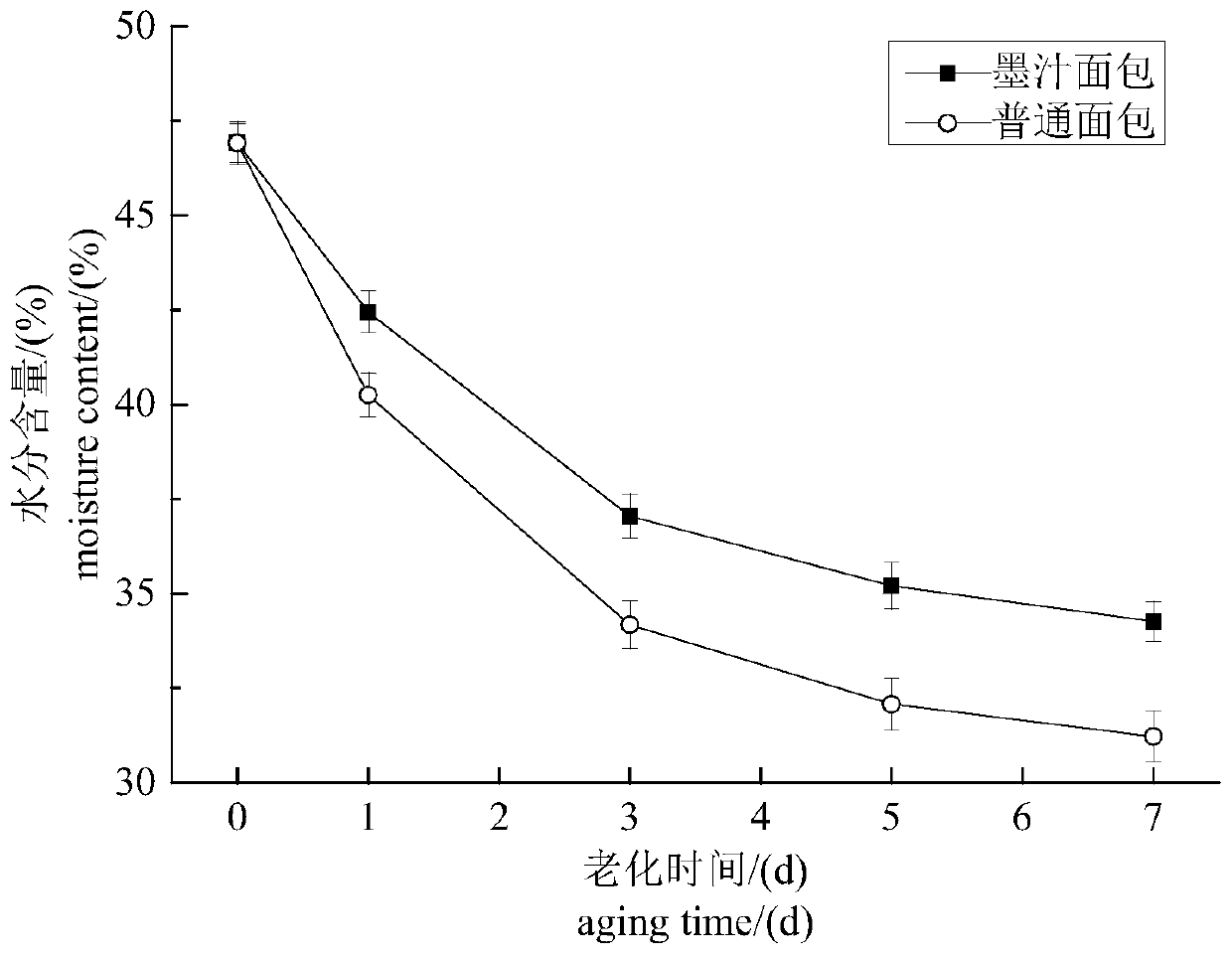

A production method, squid ink technology, applied in the direction of dough processing, baking, baked food with modified ingredients, etc., to achieve the effect of small changes, small aging rate, and single nutritional structure improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of cuttlefish ink bread, comprises the steps:

[0041] 1. Pretreatment of squid ink sacs: thaw the frozen tabby squid ink sacs in running water, cut the ink sacs and soak the whole ink sacs including the skin of the sacs in deionized water of equal volume overnight at 8000r min -1 The supernatant was removed after centrifugation at a speed of 10 min, and the precipitate was freeze-dried to obtain the crude squid melanin;

[0042] Two, enzymatic hydrolysis of squid ink melanin crude product, add the deionized water that solid-liquid ratio is 1:50 in the above-mentioned crude product, adjust pH to 10.0, add the enzyme of 4260U / g (select the alkaline product produced by Nanning Pangbo Bioengineering Co., Ltd. Protease), after enzymatic hydrolysis at 51°C for 4.5h, high temperature inactivation at 100°C for 10min; then filter through a 200-mesh sieve and store the filtrate at low temperature at 4°C for later use;

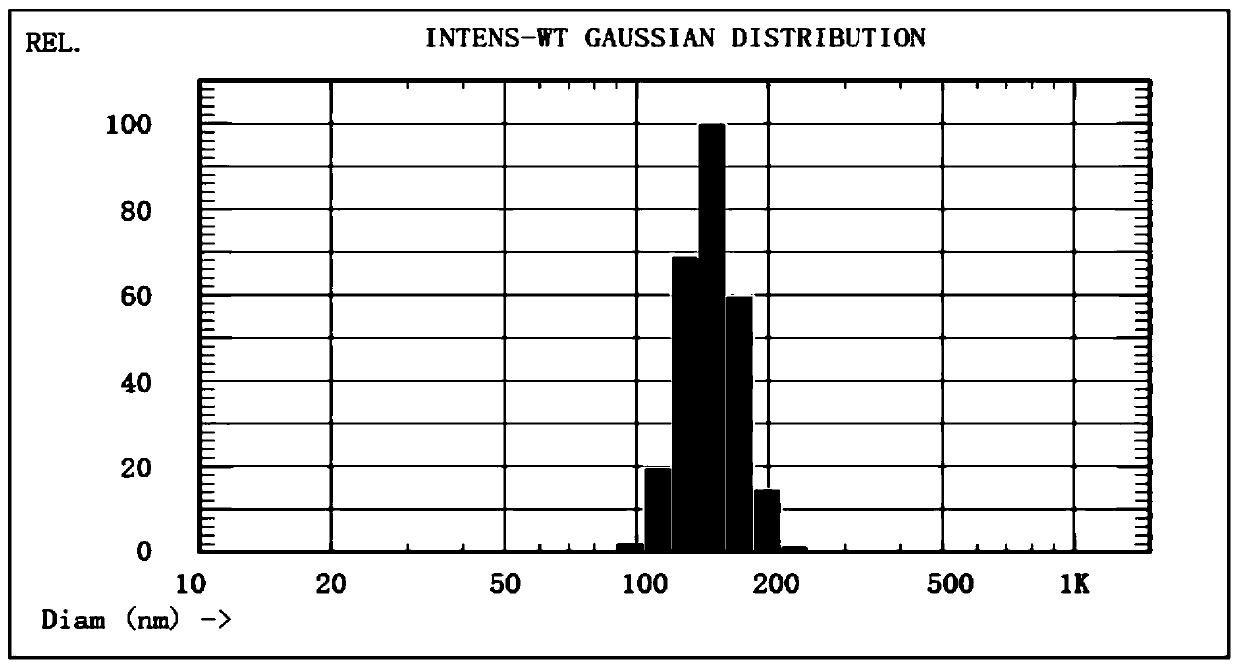

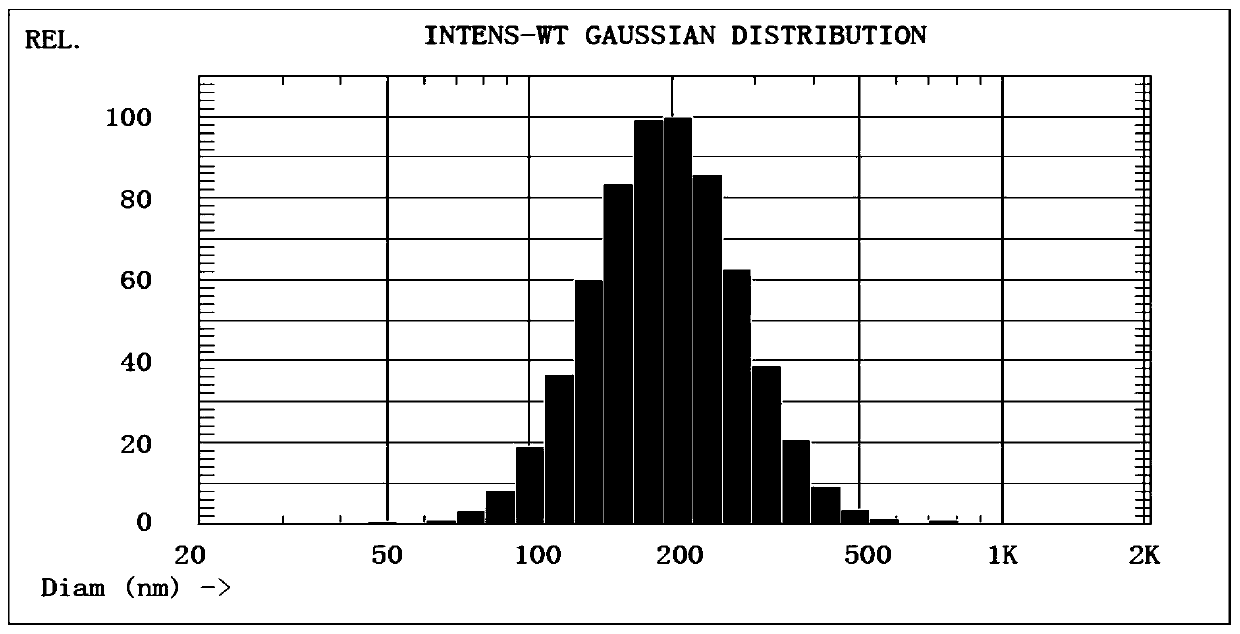

[0043] 3. Dynamic ultra-high ...

Embodiment 2

[0059] A kind of preparation method of cuttlefish ink bread, comprises the steps:

[0060] 1. Pretreatment of squid ink sacs: thaw the frozen tabby squid ink sacs in running water, cut the ink sacs and soak the whole ink sacs including the skin of the sacs in deionized water of equal volume overnight at 8000r min -1 The supernatant was removed after centrifugation at a speed of 10 min, and the precipitate was freeze-dried to obtain the crude squid melanin;

[0061] Two, enzymatic hydrolysis of squid ink melanin crude product, add the deionized water that solid-liquid ratio is 1:40 in the above-mentioned crude product, adjust pH to 9.0, add the enzyme of 4060U / g (select the alkaline product produced by Nanning Pangbo Bioengineering Co., Ltd. Protease), after enzymatic hydrolysis at 48°C for 4.0h, inactivated at 100°C for 10min at high temperature; then filter through a 200-mesh sieve and store the filtrate at low temperature at 4°C for later use;

[0062] 3. Dynamic ultra-high...

Embodiment 3

[0066] A kind of preparation method of cuttlefish ink bread, comprises the steps:

[0067] 1. Pretreatment of squid ink sacs: thaw the frozen tabby squid ink sacs in running water, cut the ink sacs and soak the whole ink sacs including the skin of the sacs in deionized water of equal volume overnight at 8000r min -1 The supernatant was removed after centrifugation at a speed of 10 min, and the precipitate was freeze-dried to obtain the crude squid melanin;

[0068] Two, enzymatic hydrolysis of squid ink melanin crude product, add the deionized water that solid-liquid ratio is 1:60 in the above-mentioned crude product, adjust pH to 11.0, add the enzyme of 4460U / g (select the alkaline product produced by Nanning Pangbo Bioengineering Co., Ltd. Protease), after enzymatic hydrolysis at 54°C for 5.0h, high temperature inactivation at 100°C for 10min; then filter through a 200-mesh sieve and store the filtrate at low temperature at 4°C for later use;

[0069] 3. Dynamic ultra-high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com