Method for synthesizing DDR molecular sieve membrane

A molecular sieve and synthetic mother liquor technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as hindering the industrial application of DDR molecular sieve membranes, and achieve the effects of shortening synthesis time, increasing crystallization rate, and increasing alkalinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

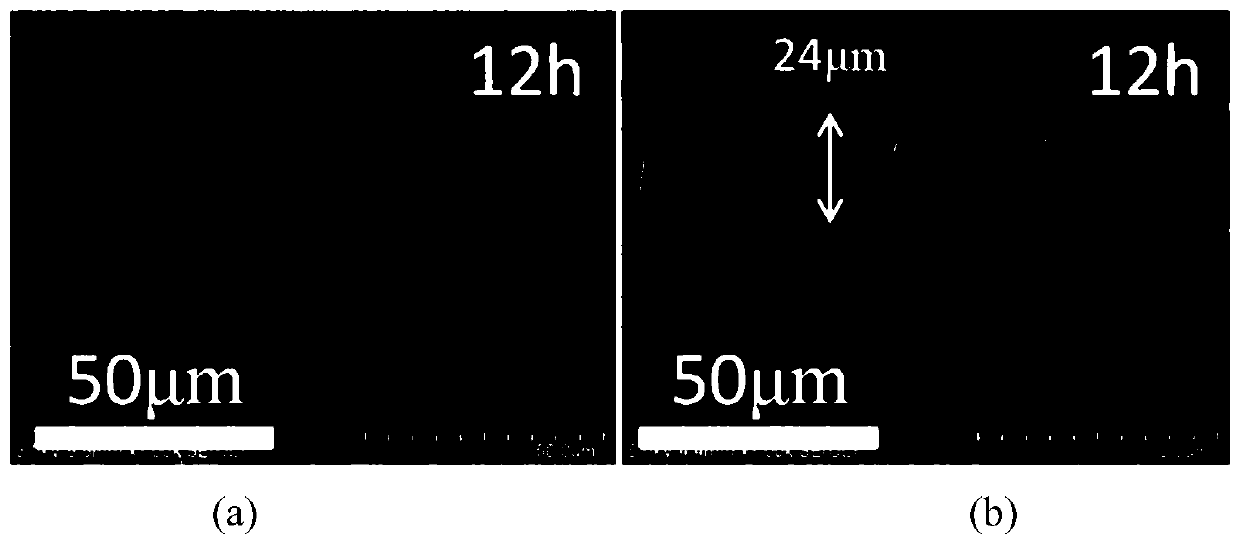

[0034] A method for synthesizing DDR molecular sieve membranes with a molar ratio of 1SiO 2 :50H 2 O:0.4Adam:0.2TEAOH mother liquor, crystallized at 220°C for 2 hours to prepare all-silicon DDR molecular sieve membrane.

[0035] In this example, SSZ-13 molecular sieve membranes were synthesized by heating in a traditional oven. The specific steps are as follows:

[0036] Step 1: Synthetic formula of all-silicon DDR molecular sieve: 1.0SiO 2 :4.0EDA:0.5ADA:100H 2 O (EDA: ethylenediamine, ADA: amantadine). Mix ethylenediamine, water and adamantane ammonium, stir for 1 hour, then add ethyl orthosilicate, stir overnight at room temperature to obtain a synthetic mother liquor. Crystallize at 433K for 24 days to obtain an all-silicon DDR molecular sieve. The molecular sieve crystals are relatively large, about 8 microns. After being milled by a ball mill, the crystals are crushed to below 500 nanometers.

[0037]Step 2: Select a porous ceramic tube with a pore size of 100nm a...

Embodiment 2

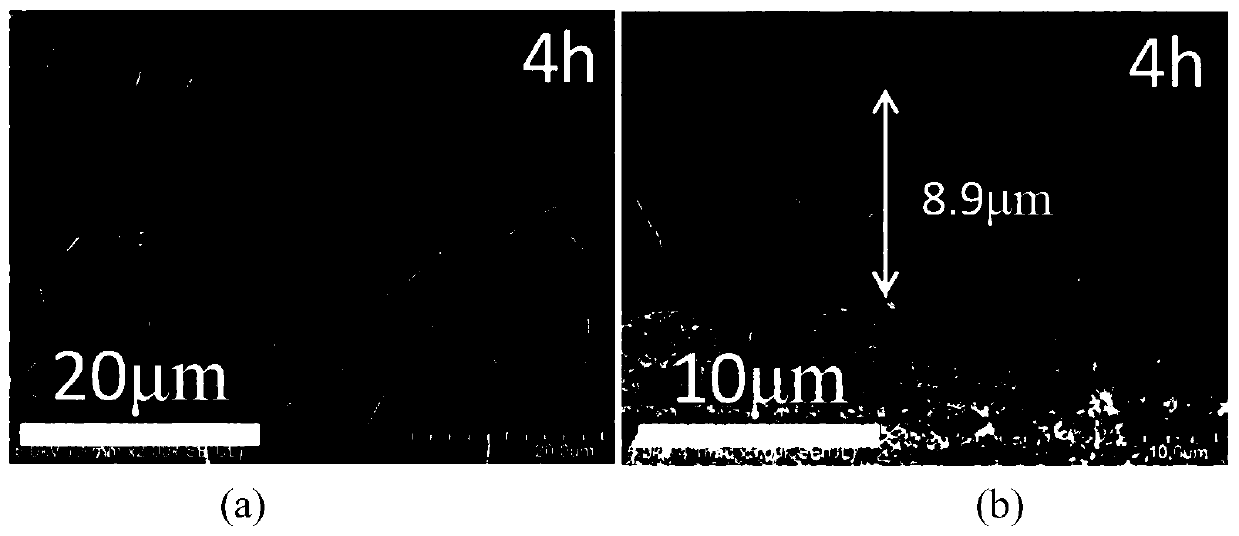

[0046] A method for synthesizing a DDR molecular sieve membrane, the difference from Example 1 is: crystallization at 220° C. for 4 hours to prepare an all-silicon DDR molecular sieve membrane. All the other steps are the same as in Example 1.

[0047] The surface and profile of gained SSZ-13 molecular sieve membrane are as follows figure 2 As shown in the figure, it can be seen from the figure that the surface of the carrier is completely covered by diamond-shaped DDR crystals, and the cross-linking between the crystals is very good (see figure a); the thickness of the film is relatively uniform, about 8.9 microns (see figure b).

[0048] The CO of the SSZ-13 molecular sieve membrane tube 2 / CH 4 The gas separation test results are shown below, at 0.2MPa, its CO 2 The average value of the permeability is 0.78×10 -7 mol / (m 2 s Pa), CO 2 / CH 4 The average separation selectivity is 165.

Embodiment 3

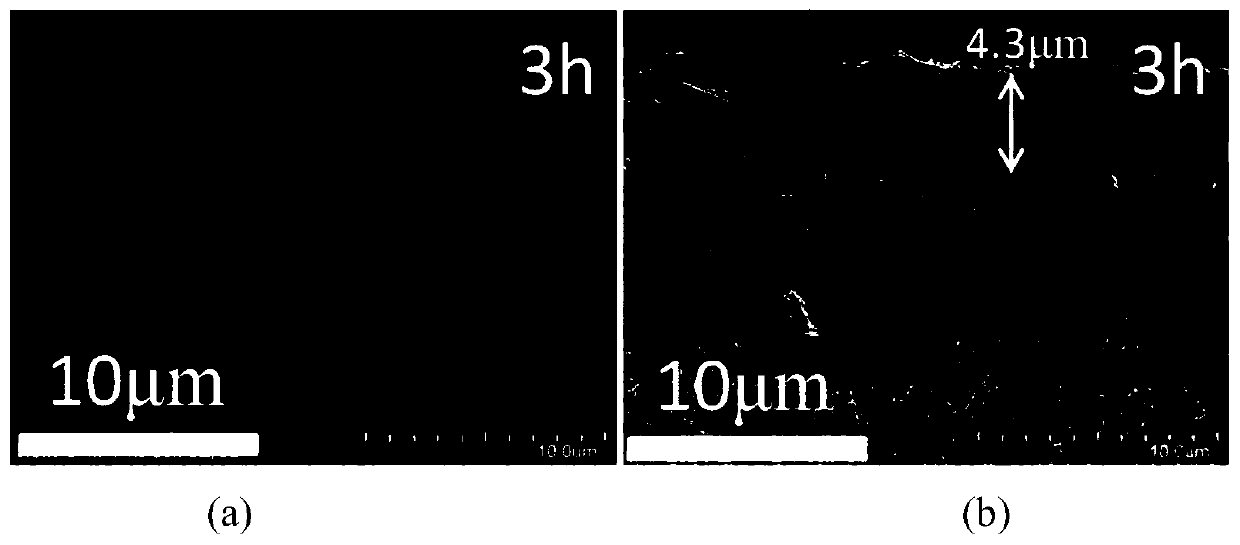

[0050] A method for synthesizing a DDR molecular sieve membrane, the difference from Example 1 is: crystallization at 220° C. for 3 hours to prepare an all-silicon DDR molecular sieve membrane. All the other steps are the same as in Example 1.

[0051] The surface and profile of gained DDR molecular sieve membrane are as follows image 3 As shown in the figure, it can be seen from the figure that the surface of the carrier is completely covered by diamond-shaped DDR crystals, and the cross-linking between the crystals is very good (see figure a); the thickness of the film is relatively uniform, about 4.3 microns (see figure b).

[0052] The DDR molecular sieve membrane tubes CO 2 / CH 4 The gas separation test results are shown below, at 0.2MPa, its CO 2 The average value of the permeability is 1.5×10 -7 mol / (m 2 s Pa), CO 2 / CH 4 The average separation selectivity is 155.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com