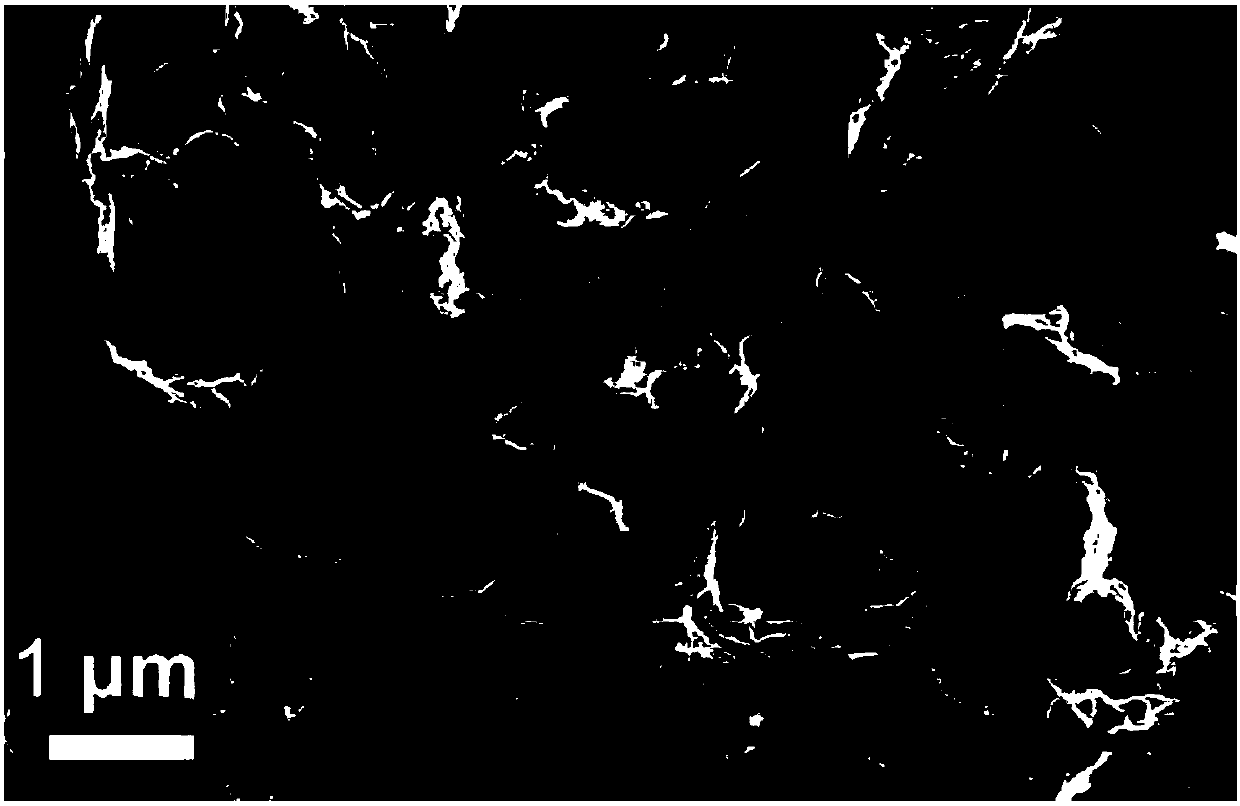

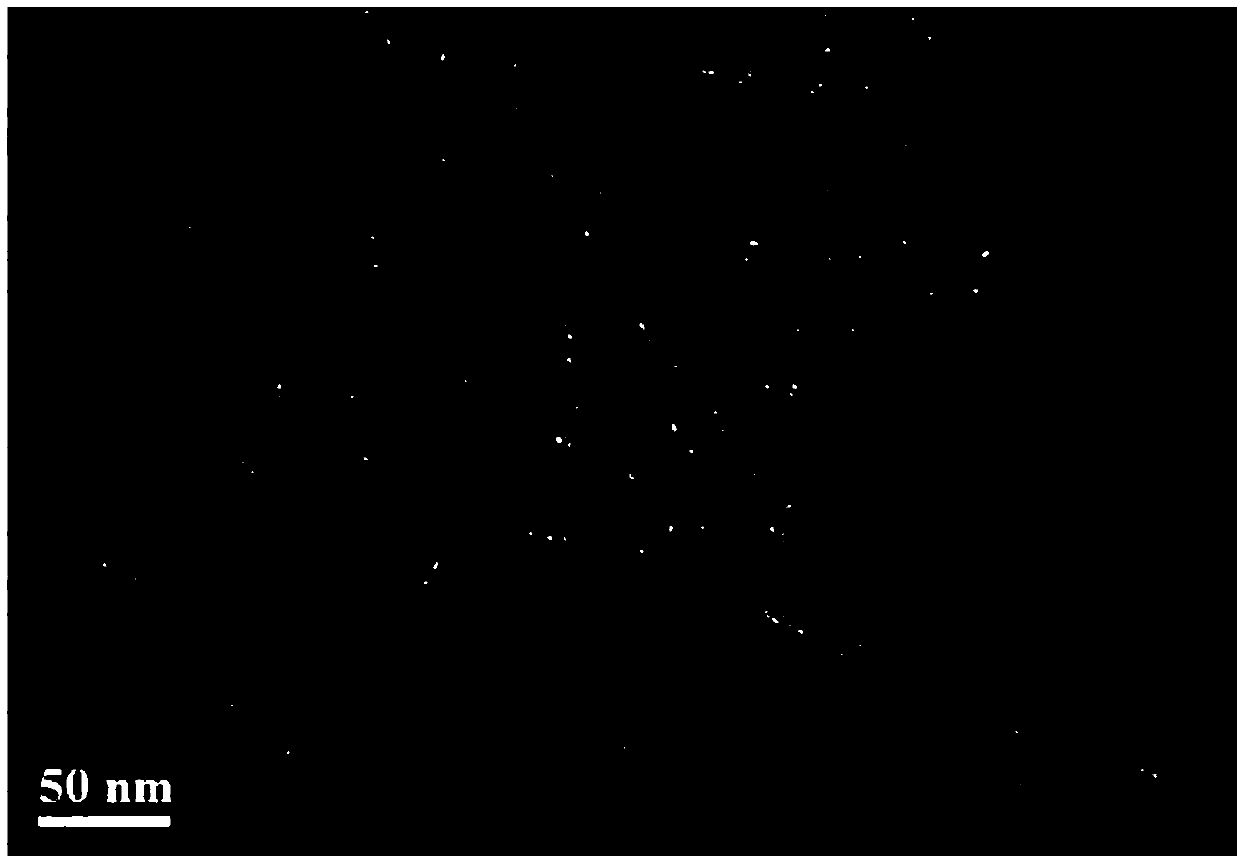

Nitrogen-doped porous graphene and preparation method thereof

A technology of porous graphene and nitrogen doping, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as harsh reaction conditions, poor material performance, complex synthesis process, etc., and achieve higher decomposition temperature and stronger Effects of dispersion and half-wave potential improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Graphene oxide adopts the improved Hummer's method, that is, take 1g of graphite powder, 0.5g of sodium nitrate and add 23ml of concentrated sulfuric acid, place them in an ice bath environment and mix them mechanically. Then 3 g of potassium permanganate was added and stirred for 2 hours, during which the temperature of the reaction system was kept not higher than 20°C. When the reaction system returns to room temperature, slowly add 70mL of deionized water to the reaction system to oxidize and expand the graphite. The reaction is carried out for 0.5h, then continue to add 70mL of deionized water for dilution, and then slowly add 20mL of 30% hydrogen peroxide until the reaction system Change color and finally cool to room temperature. Add 2L of 5% dilute hydrochloric acid to the above reaction system for dilution, dissolve the remaining undissolved manganese dioxide, and then filter. Afterwards, rinse with deionized water and centrifuge to remove acid until the pH of ...

Embodiment 2

[0050] Graphene oxide adopts the improved Hummer's method, that is, take 1g of graphite powder, 1g of sodium nitrate and add 25ml of concentrated sulfuric acid and place them in an ice bath environment for mechanical mixing. Then 4 g of potassium permanganate was added and stirred for 8 hours, during which the temperature of the reaction system was kept not higher than 20°C. When the reaction system returns to room temperature, slowly add 100mL deionized water to the reaction system to oxidize and expand the graphite. The reaction is carried out for 2h, then continue to add 100mL deionized water for dilution, and then slowly add 20mL 30% hydrogen peroxide until the reaction system changes color. , and finally cooled to room temperature. Add 3L of 5% dilute hydrochloric acid to the above reaction system for dilution, dissolve the remaining undissolved manganese dioxide, and then filter. Afterwards, rinse with deionized water and centrifuge to remove acid until the pH of the re...

Embodiment 3

[0054] Graphene oxide adopts the improved Hummer's method, that is, take 1g of graphite powder, 0.3g of sodium nitrate and add 20ml of concentrated sulfuric acid, place them in an ice bath environment and mix them mechanically. Then 5 g of potassium permanganate was added and stirred for 1 hour, during which the temperature of the reaction system was kept not higher than 20°C. When the reaction system returns to room temperature, slowly add 40 mL of deionized water to the reaction system to oxidize and expand the graphite. The reaction is carried out for 1 hour, then continue to add 40 mL of deionized water for dilution, and then slowly add 30 mL of 30% hydrogen peroxide until the reaction system changes color. , and finally cooled to room temperature. Add 400 mL of 5% dilute hydrochloric acid to the above reaction system for dilution, dissolve the remaining undissolved manganese dioxide, and then filter. Afterwards, rinse with deionized water and centrifuge to remove acid un...

PUM

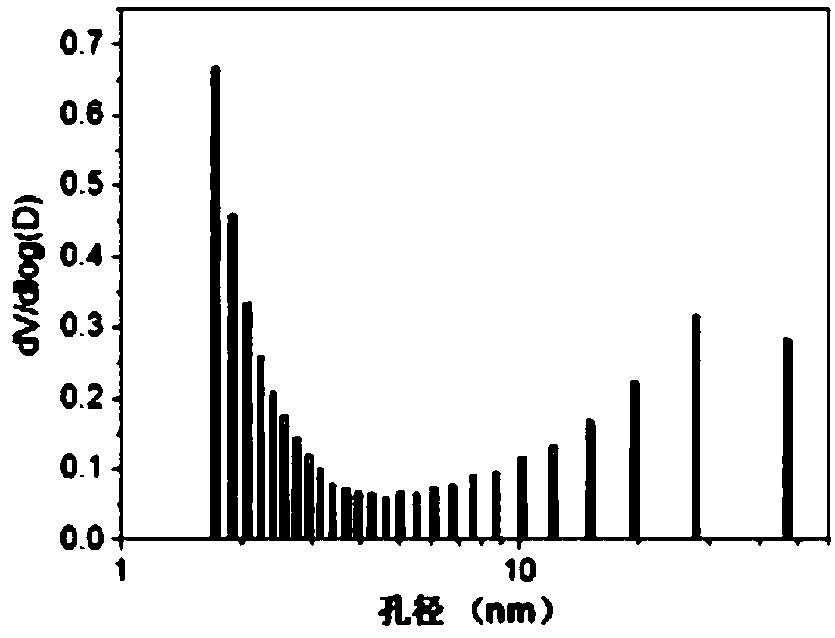

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com