Three-dimensional TiO2 photoelectrode with efficient visible light response as well as construction and application thereof

A visible light and photoelectrode technology, applied in electrodes, light water/sewage treatment, electrolysis process, etc., can solve the problems of low degradation and removal efficiency, unsatisfactory catalytic oxidation performance, etc., and achieve high-efficiency photocatalytic oxidation surface characteristics, high-efficiency visible light Photoelectric catalytic performance and the effect of promoting efficient photoelectric synergistic catalytic oxidation removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

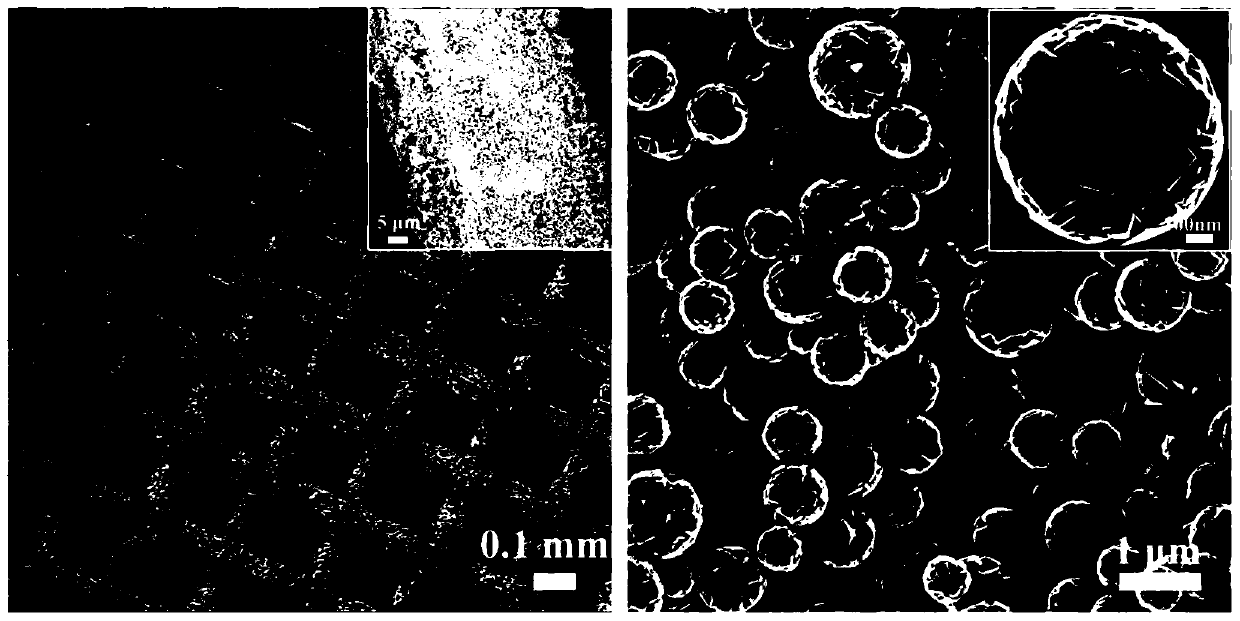

[0038] An Anatase {001} TiO with Highly Exposed {001} Facets 2 The preparation method of / Ti photoanode specifically comprises the following steps:

[0039] Fold the metal Ti mesh into double layers and cut it into 3.5×4.5cm 2 Size, in chemical polishing solution (volume ratio: HNO 3 :HF:H 2 (O=5:1:25) soaked in 30s for chemical polishing, then ultrasonically cleaned in water and ethanol for 15min, and then cleaned the Ti grid with deionized water immediately, and dried for later use. Add 30mL deionized water and 27μL hydrofluoric acid (≥38wt%) to 100mL polytetrafluoroethylene substrate and mix well, then put the dry metal Ti mesh through chemical polishing into it, and the polytetrafluoroethylene substrate Put it into a high-pressure reactor and heat it with water at 180°C for 4 hours. After the reaction is completed, cool it down to room temperature, rinse the surface with deionized water, and let it dry naturally. Calcined at 450°C for 3h in an air atmosphere with a heat...

Embodiment 2

[0041] Compared with Example 1, most of them are the same, except in this example:

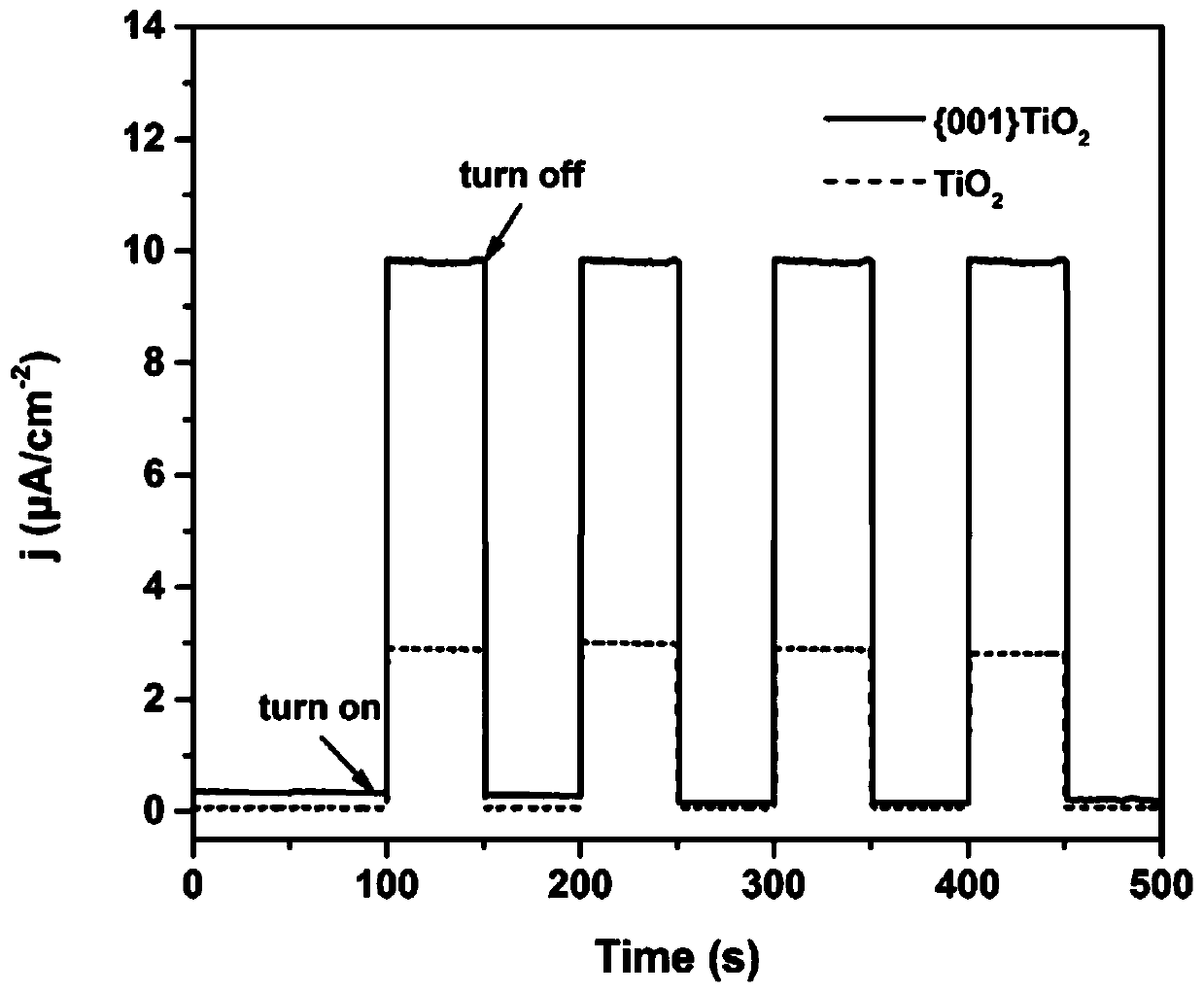

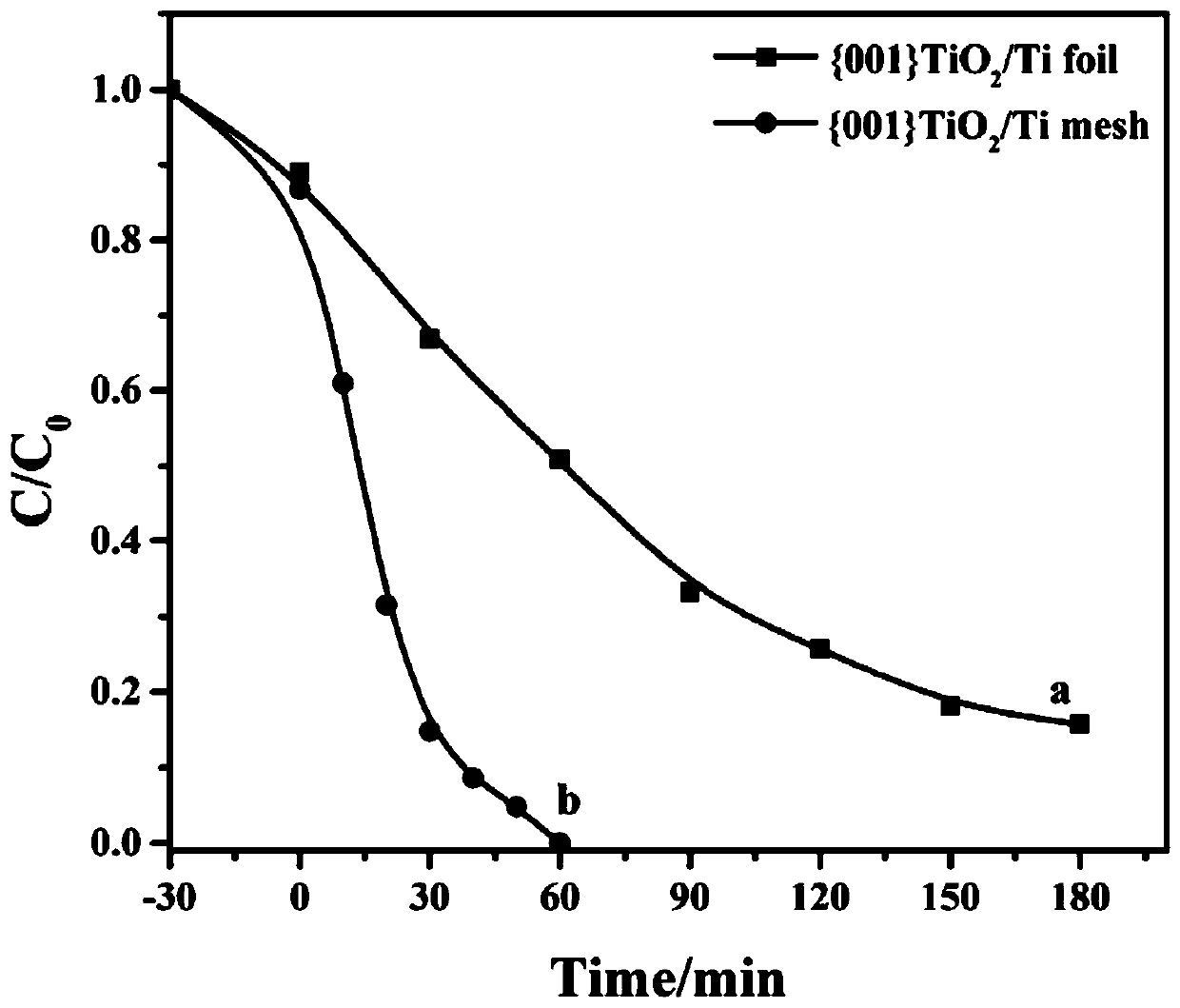

[0042] Replace the metal Ti mesh with a metal Ti plate to get {001}TiO 2 / Ti(foil) electrode material. The {001}TiO obtained in case 1 based on the Ti network 2 / Ti(mesh) and {001}TiO 2 / Ti(foil) under simulated sunlight, the photoelectric catalytic degradation of dimethyl phthalate (DMP) experiment, the specific steps are as follows:

[0043] The experiment of photocatalytic degradation of DMP was carried out in a cuboid quartz degradation cell with a volume of 50ml, using a three-electrode degradation system, with {001}TiO 2 / Ti foil (or {001}TiO 2 / Ti mesh) the photoelectrode is the working electrode, the platinum sheet is the counter electrode, the saturated calomel electrode is the reference electrode, the distance between the working electrode and the counter electrode is 3cm, and the effective photoelectrode area is 3.5×4.5cm 2 . Use 0.1mol·L -1 Sodium sulfate deionized water sol...

Embodiment 3

[0045] A Highly Exposure {001}TiO Supported by Carbon Quantum Dots 2 / Ti photoelectrode (CQDs-{001}TiO 2 / Ti) preparation method, specifically comprises the following steps:

[0046] (1) Cut the metal Ti mesh into 1.5×1.5cm 2 Size, in chemical polishing solution (volume ratio: HNO 3 :HF:H 2 (O=5:1:25) soaked in 30s for chemical polishing, then ultrasonically cleaned in water and ethanol for 15min, and then cleaned the Ti grid with deionized water immediately, and dried for later use. Add 30mL deionized water and 27μL hydrofluoric acid (≥38wt%) to 100mL polytetrafluoroethylene substrate and mix well, then put the dry metal Ti mesh through chemical polishing into it, and the polytetrafluoroethylene substrate Put it into a high-pressure reactor and heat it with water at 180°C for 4 hours. After the reaction is completed, cool it down to room temperature, rinse the surface with deionized water, and let it dry naturally. Calcined at 450°C for 3h in an air atmosphere with a hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com