Post-extraction process for swine alpha-interferon

An extraction process and interferon technology, which is applied in the direction of interferon, cytokines/lymphokines/interferons, peptide preparation methods, etc., can solve the problems of complex extraction process, high cost, poor yield, etc., and achieve high purity, Cost savings and mild elution conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1. Construction of Recombinant Porcine α-Interferon Engineering Bacteria

[0078] Step 1. Obtaining the target gene

[0079] We found the original gene sequence of boar α-interferon (SEQ ID NO.3) on the NCBI website, deleted the original signal peptide of boar α-interferon, and performed statistical analysis on the amino acids with degenerate codons , selected codons with high usage frequency, obtained a new recombinant porcine α-interferon gene sequence (SEQ ID NO.1), entrusted Sangon Bioengineering (Shanghai) Co., Ltd. to carry out whole gene synthesis, and obtained the target gene.

[0080] Design primers, add EcoR I restriction site to the 5' end of the target gene, and add Not I restriction site to the 3' end by PCR reaction. After the PCR product was subjected to 1.5% agarose gel electrophoresis, a 525bp fragment was recovered with a DNA purification and recovery kit. The DNA sequence of the fragment is shown in SEQ ID NO.2.

[0081] The nucleotide seque...

Embodiment 2

[0110] Embodiment 2. The fermentation process of recombinant porcine alpha-interferon

[0111] 1. Screening of multi-copy strains

[0112] Streak-inoculate the single colonies of positive clones obtained in Example 1 onto YPD solid medium containing 300 μg / ml, 600 μg / ml, and 900 μg / ml bleomycin in sequence, and screen out stable multi-copy high-yielding strains. Specific steps are as follows:

[0113] Inoculate the single colonies of positive clones on the YPD plate containing 100 μg / ml bleomycin to the YPD selective plate medium containing 300 μg / ml bleomycin using the “three-step streaking method” and culture at 30°C for 3-5 days. Colonies were observed after days.

[0114] Inoculate a single colony with good growth on the YPD plate containing 300 μg / ml bleomycin to the YPD selective plate medium containing 600 μg / ml bleomycin using the “three-step streaking method” and culture at 30°C for 3- Colonies were observed after 5 days.

[0115] Inoculate a single colony with go...

Embodiment 3

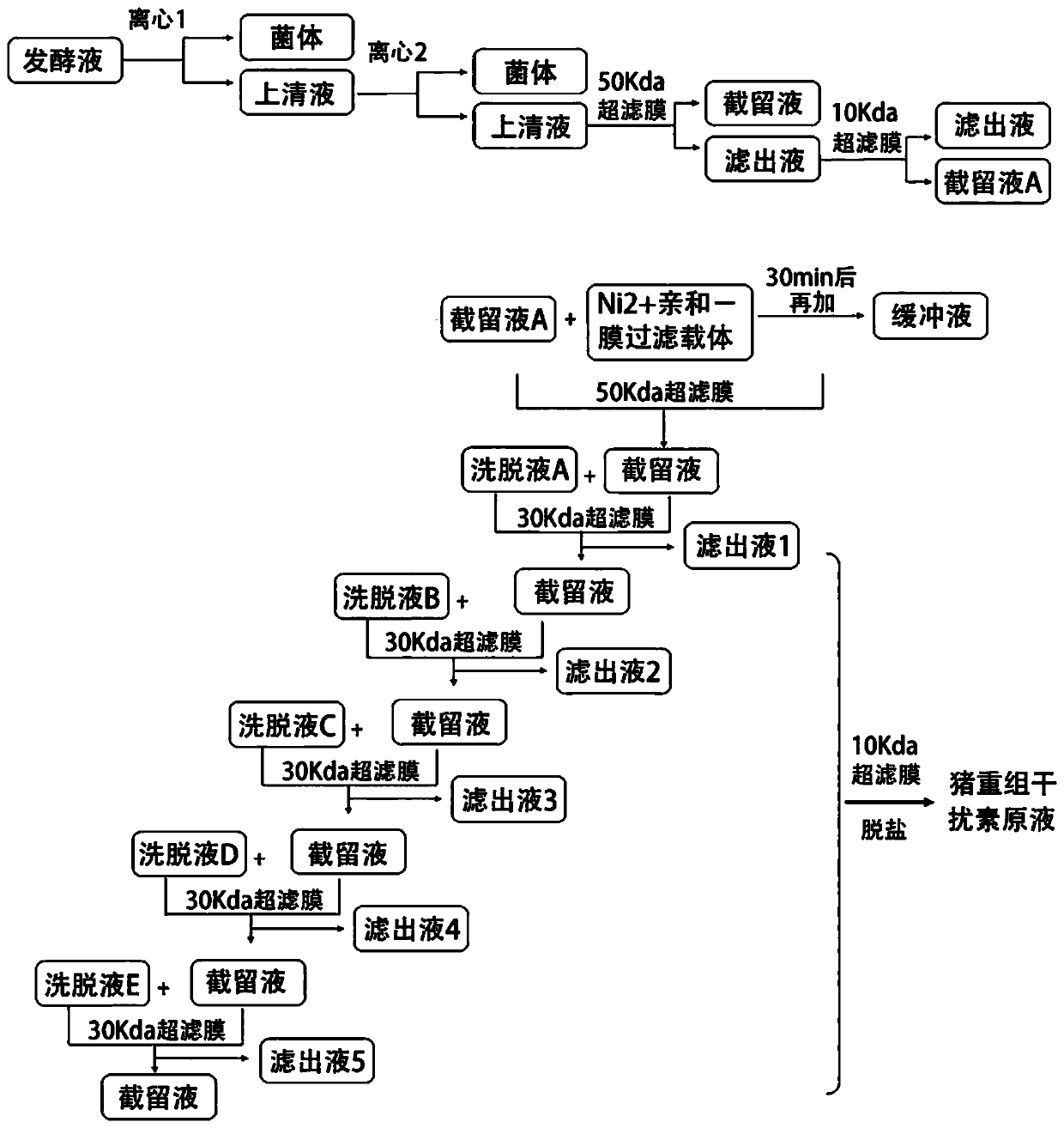

[0132] Embodiment 3. Post-extraction process of porcine alpha-interferon

[0133] Step 1: Put the jar

[0134] First, the recombinant Pichia strain (CCTCC M 2019749) is carried out according to the method of Example 2 for the screening of multi-copy bacterial strains, primary seed culture, and secondary seed cultivation, and then the secondary seed liquid is pressed at 15% (v / v) The inoculum size was transferred to 15T (ton) induction medium for fermentation culture (the method is the same as in Example 2) to obtain Pichia pastoris fermentation broth. The porcine alpha interferon quantitative detection kit was used to measure the concentration of porcine recombinant alpha interferon in the Pichia pastoris fermentation broth, and the concentration of porcine alpha interferon in the fermentation broth was measured to be 20-22g / L.

[0135] Step 2: Centrifuge

[0136] Centrifuge the fermented liquid in the storage tank through a centrifuge, the centrifuge speed is 12000rpm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com