Graphene modified two-component waterborne polyurethane anticorrosive coating and preparation method thereof

A water-based polyurethane and graphene modification technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve toxic and harmful problems, and achieve the effects of improving environmental protection performance, prolonging corrosion service period, and excellent anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] On the other hand, the embodiments of the present invention provide a method for preparing a graphene-modified two-component waterborne polyurethane anti-corrosion coating, comprising the following steps:

[0056] S01. take each component according to the formula of graphene modified two-component waterborne polyurethane anticorrosion coating of the present invention;

[0057] S02. After the first mixing treatment of the formula A component deionized water, water-based dispersant, and substrate wetting agent, add water-based graphene slurry, environmentally friendly anti-rust fillers, and other pigments and fillers for the second mixing treatment; add disinfectant Foaming agent carries out the 3rd mixed treatment, makes mixed slurry;

[0058] S03. Grinding the mixed slurry until the fineness reaches ≤30um to obtain a grinding slurry;

[0059] S04. Add multifunctional adjustment aids, anti-flash rust agents, and water-based hydroxyacrylic acid emulsions to the grinding ...

Embodiment 1

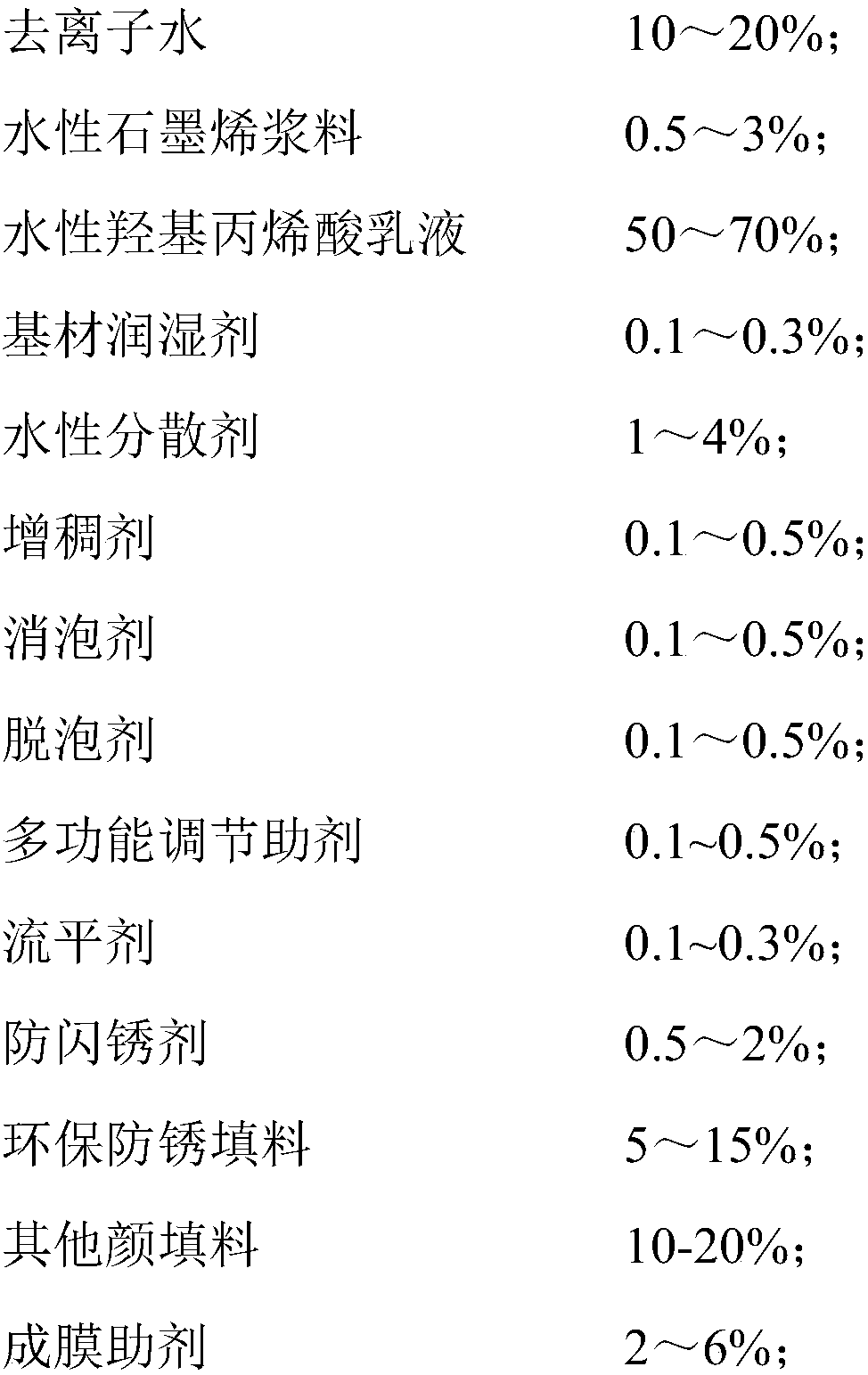

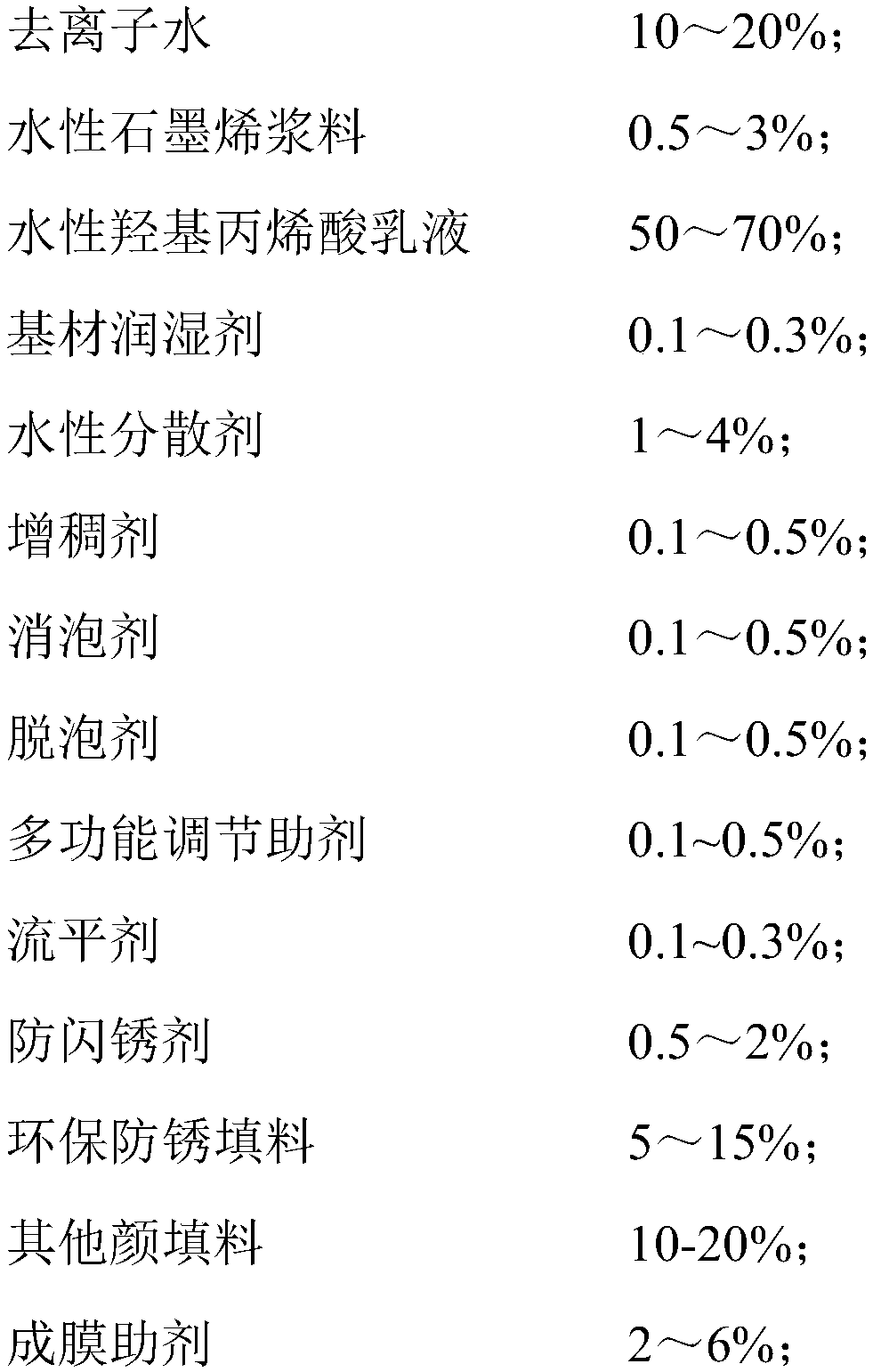

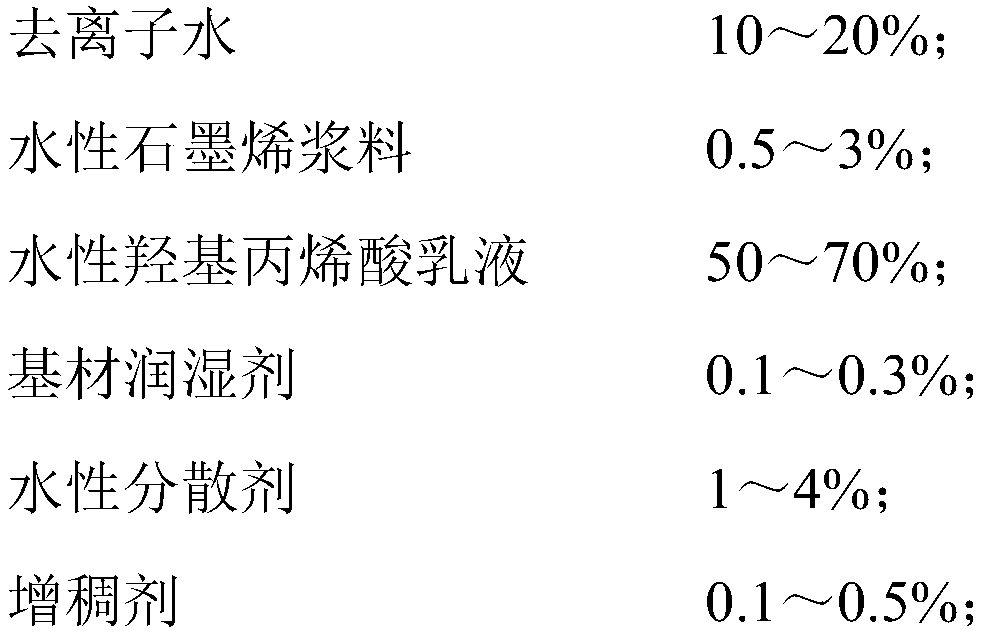

[0071] A graphene-modified two-component water-based polyurethane anti-corrosion coating, including A component and B component;

[0072] Taking the total weight of the A component as 100%, the A component includes the following components in the following weight percentages: deionized water 12wt%, water-based graphene slurry 1wt%, water-based hydroxyacrylic acid emulsion ( Bayhydrol A2470) 57wt%, substrate wetting agent 0.25wt%, water-based dispersant 1.6wt%, thickener 0.25wt%, defoamer 0.2wt%, defoamer 0.1wt%, multi-functional adjustment aid 0.2wt %, leveling agent 0.2wt%, anti-flash rust agent 1wt%, aluminum tripolyphosphate 2.55wt%, molybdenum modified zinc phosphate 2.5wt%, barium sulfate 3wt%, mica powder 4wt%, titanium dioxide 10wt%, film-forming Auxiliary 4.4wt%. Wherein, the water-based graphene in the water-based graphene slurry is modified graphene, and the modified graphene is a non-covalent bond functionalization composed of graphene and a planar aromatic ring ad...

Embodiment 2

[0081] A graphene-modified two-component water-based polyurethane anti-corrosion coating, including A component and B component;

[0082] Based on the total weight of the A component as 100%, the A component includes the following components in the following weight percentages: deionized water 11wt%, water-based graphene slurry 1.5wt%, water-based hydroxyacrylic acid emulsion Wanhua (Antkote2042) 63wt%, substrate wetting agent 0.2wt%, water-based dispersant 1.75wt%, thickener 0.22wt%, defoamer 0.3wt%, defoamer 0.1wt%, multi-functional adjustment assistant 0.2wt%, leveling agent 0.23wt%, anti-flash rust agent 1wt%, iron-titanium powder 3, molybdenum modified zinc phosphate 3wt%, mica powder 2.7wt%, titanium dioxide 7wt%, coalescent 4.8wt%. Wherein, the water-based graphene in the water-based graphene slurry is modified graphene, and the modified graphene is a non-covalent bond functionalization composed of graphene and a planar aromatic ring adsorbed on the surface of the graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com