A kind of decontamination self-cleaning insulator protective agent and preparation method thereof

A self-cleaning, insulator technology that can be used in biocide-containing paints, antifouling/underwater coatings, coatings, etc., to solve problems such as restricted use, loss of superhydrophobicity, poor wear resistance and adhesion , to achieve good economic and social benefits, excellent cleaning and decontamination ability, and excellent permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

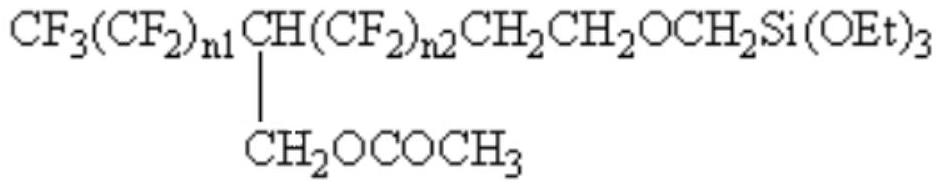

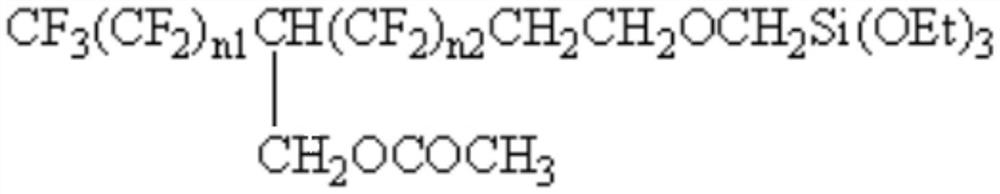

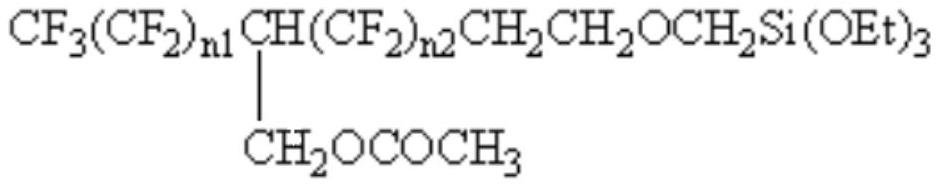

[0044] In the cleaning and self-cleaning protective agent for insulators provided by the present invention, the surface treatment agent includes 15-35 parts of hydrophobic nanoparticles, preferably 20-30 parts by weight. The hydrophobic nanoparticles in the present invention are hydrophobic nano white carbon black powder, the particle diameter of the hydrophobic nano white carbon black powder is 50-200nm, and the preparation method of the hydrophobic nano white carbon black powder comprises the following steps : Nano white carbon black powder, bis-(γ-triethoxysilylpropyl) tetrasulfide, water, azobisisobutyronitrile and ethanol are mixed, the nano white carbon black powder, bis- The mass ratio of (γ-triethoxysilylpropyl) tetrasulfide, water, azobisisobutyronitrile and ethanol is (4-8): (2-5): (0.5-1): (0.05 -0.5): (3-6), after stirring in a reactor at 50-120°C for 3-6h to obtain mixture 1, naturally cool to room temperature, and extract the above mixture 1 at 50-80°C with a Sox...

Embodiment 1

[0049] 1) Configuration of mixed solvent: Stir and disperse 5 parts of isopropanol, 20 parts of 120# gasoline, 56 parts of trifluorotrichloroethane and 10 parts of ethanol evenly to obtain a mixed solvent;

[0050] 2) The configuration of the bottom treatment agent: Add 3 parts of hydrogen-containing silicone oil to 89 parts of the above mixed solvent, and then add 8 parts of micron-sized powder particles at a speed of 1500rpm and continue to disperse at high speed for 15 minutes to obtain the bottom treatment agent ;

[0051] 3) Configuration of surface treatment agent: Stir and mix 15 parts of low surface energy resin and 55 parts of ethyl acetate, then add 30 parts of hydrophobic nanoparticles and continue high-speed dispersion for 25 minutes at a speed of 5000 rpm to obtain surface treatment agent ;

[0052] The hydrogen-containing silicone oil in the present invention has an active hydrogen content of 0.35%, a viscosity of 110mPa·s,

[0053] Described hydrophobic nano p...

Embodiment 2

[0055] 1) Configuration of the mixed solvent: Stir and disperse 15 parts of isopropanol, 25 parts of 120# gasoline, 52 parts of trifluorotrichloroethane and 8 parts of ethanol evenly to obtain the mixed solvent;

[0056] 2) The configuration of the bottom treatment agent: add 6 parts of hydrogen-containing silicone oil to 82 parts of the above mixed solvent, and then add 12 parts of micron-sized powder particles at a speed of 3000rpm and continue to disperse at high speed for 20 minutes to obtain the bottom treatment agent ;

[0057] 3) Configuration of surface treatment agent: Stir and mix 10 parts of low surface energy resin and 65 parts of ethyl acetate, then add 25 parts of hydrophobic nanoparticles and continue to disperse at high speed for 20 minutes at a speed of 3000 rpm to obtain surface treatment agent ;

[0058] The active hydrogen content of the hydrogen-containing silicone oil in the present invention is 0.6%, and the viscosity is 580mPa·s; the hydrophobic nano-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com