Preparation method of lithium titanate-carbon nanotube electrode material

A technology of carbon nanotubes and electrode materials, which is applied in the direction of battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of large capacitance attenuation, pore blockage, difficulty in uniform dispersion of graphene, etc., to improve the performance of conductive electrons, reduce the Migration impedance, the effect of overcoming capacity fading and poor rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Weigh 3.1251g of carbon nanotubes (dispersed in NMP, the content is 4wt%) and NMP mixture and 12.5062g of ethylene glycol, and add them to a 100mL reaction kettle, and then add 4.457g in the glove box Isopropyl titanate; put it in a homogeneous reactor at 200°C for 12 hours at a rotation speed of 10r / min after ventilation to obtain slurry A;

[0035] (2) Cool the slurry A, then suction filter, wash with 10mL of methanol, take 2.0190g of the product and put it in the reaction kettle, then add 5.0746g of lithium hydroxide aqueous solution (1.0mol / L), and then place it at 200°C In a homogeneous reactor, the reaction speed was 10r / min for 12h; slurry B was obtained;

[0036] (3) Suction filter slurry B to separate the solid, take the solid and place it in a tube furnace, and heat it at 700°C 2 Sintering in the atmosphere for 4h to obtain the lithium titanate electrode material;

[0037] (4) placing the NMP solution (3wt%) of lithium titanate electrode material, PVDF, ...

Embodiment 2

[0048] The difference between the second embodiment and the first embodiment is that the sintering temperature in the step (3) of the second embodiment is changed to 400° C., and the others are the same as those of the first embodiment, which will not be repeated here.

Embodiment 3

[0050] The difference between the third embodiment and the first embodiment is that the sintering temperature in the step (3) of the second embodiment is changed to 500° C., and the others are the same as the first embodiment, and will not be repeated here.

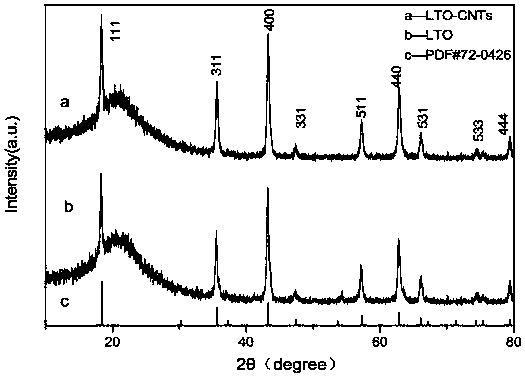

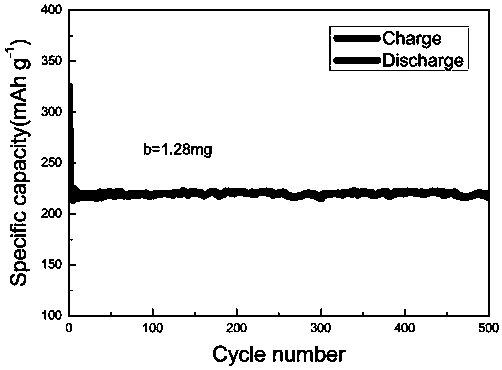

[0051] Attached from the manual Figure 7 with Figure 8 It can be analyzed that in the comparison between the above-mentioned Example 2 and Example 3, the capacity of the material sintered at 500°C is higher than that at 400°C at different sintering temperatures, at 0.4A·g -1 When the current density, the former is 250mAh / g, and the latter is 200mAh / g. The lithium titanate-carbon nanotube material prepared by sintering at 500°C can maintain a capacity of 250mAh / g at a high rate current density, and the attenuation is small. In the existing commercial product Li 4 Ti 5 o 12 At 1C, it can only reach about 170mAh / g or even less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com