Biochar-based multi-element fertilizer and preparation method thereof

A technology of biochar and primary fertilizer, applied in the field of efficient microbial fertilizer preparation, can solve the problems of unfavorable microbial survival, low nutrient content, damaged microbial inoculation rate, etc., to reduce the problem of crop growth inhibition or production reduction, simple preparation method, Effect of increasing inoculum inoculation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of biochar-based multicomponent fertilizer, comprising the steps of:

[0023] (1) Material preparation: pine wood biochar is purchased from the market, and the material parameters are shown in Table 1, and passed through a 2mm sieve for use; ammonium nitrate crystals, nitrogen content 35%, analytically pure, dissolved in 5000 ml of deionized ammonium nitrate crystals per 100 grams of ammonium nitrate crystals The proportion of water is made into ammonium nitrate solution; EM stock solution (composed of more than 80 species of microorganisms in 5 families, 10 genera, etc.) Purchased from Nanjing Amule Environmental Biotechnology Co., Ltd., mixed with 1 part of EM stock solution, 1 part of molasses, and 98 parts of deionized water (volume percentage), and cultured in a sealed environment at 25°C-35°C for 7 days to make EM active liquid (bacteria culture medium).

[0024] Table 1

[0025] carrier material pH C / N Specific surface area (m...

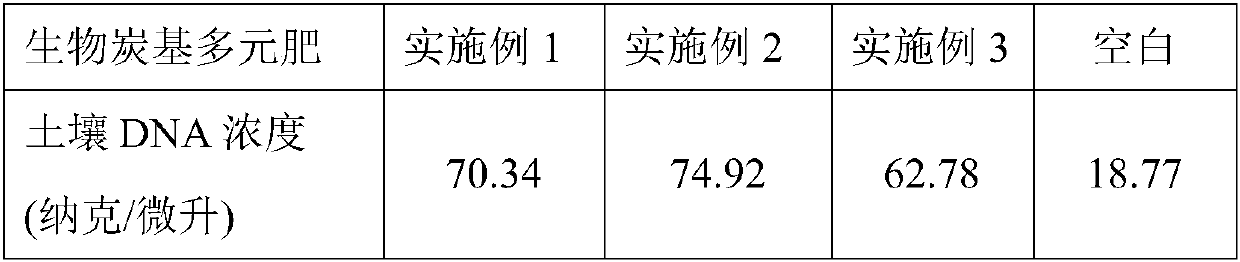

Embodiment 2

[0030] Select the modified biochar prepared in Example 1, according to the mass percentage of modified biochar and strain culture medium in an amount of 1.25:1, add the modified biochar into the strain culture liquid, and put it into 25°C constant temperature oscillation In the box, set the rotating speed to 200rpm, and shake it for 24 hours before taking it out. Put the modified biochar inoculated with EM into an oven, set the temperature to 40° C., and when the moisture content is 6% (less than 8%), the biochar-based multi-component fertilizer is made.

Embodiment 3

[0032] The modified biochar prepared in Example 1 was selected, and the modified biochar was added to the strain culture solution according to the mass percentage of the modified biochar and the strain culture medium as 1.5:1, and then placed in a constant temperature oscillation at 25°C. In the box, set the rotating speed to 200rpm, and shake it for 24 hours before taking it out. Put the modified biochar inoculated with EM into an oven, set the temperature to 40° C., and when the moisture content is 6% (less than 8%), the biochar-based multi-component fertilizer is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com