Preparation method and use method of denitrification solid-state carbon source

A solid carbon source and denitrification technology, applied in the field of water treatment, can solve the problems of small number of microorganisms, poor impact resistance, low biofilm strength, etc., to achieve the effect of strengthening interception capacity, preventing floating, and increasing the speed of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

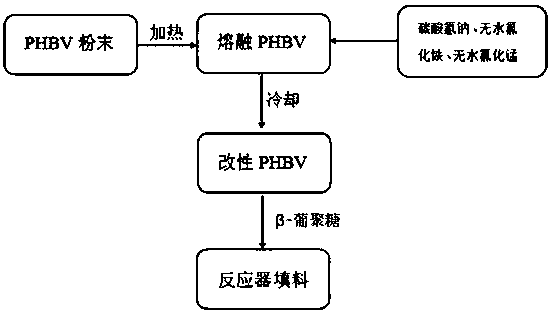

[0031] (1) Put the PHBV powder into a beaker and heat it at 160~175°C for 5 minutes. After the PHBV is melted, add the reagent with a mass ratio of PHBV: sodium bicarbonate: anhydrous ferric chloride: anhydrous manganese chloride = 100:5:0.010:0.005 into the beaker, stir at 100rpm / min for 60s, and cool naturally. into filler;

[0032] (2) Take out the filler after cooling, put it into a mesh bag with a pore size of 1.0~2.0mm, put it into a container containing 1% β-glucan aqueous solution, and shake it on a table shaker for 30s; take out the filler bag Dry it, put it into the reactor, and the reactor filling rate is 50%;

[0033] (3) No organic carbon source is added to the prepared sewage. The prepared sewage and activated sludge are mixed at a volume ratio of 1:3; an additional stirring device is added to stir at 60rpm / min; the activated sludge comes from the anaerobic pool sludge of Taiyuan Sewage Treatment Plant;

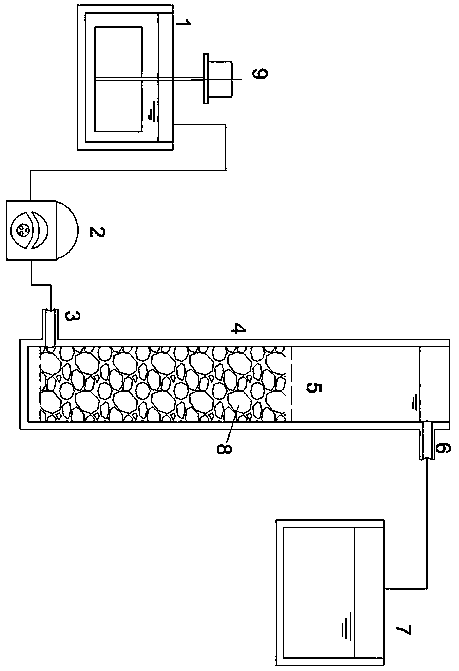

[0034] (4) The material of the reactor is plexiglass, c...

Embodiment 2

[0038] (1) The mass ratio of PHBV: sodium bicarbonate: anhydrous ferric chloride: anhydrous manganese chloride = 100: 10: 0.020: 0.010 is used for modification.

[0039] (2) The shaking time is 15s, and the mixed water sample is continuously injected for 36 hours; the rest of the filler treatment, sewage preparation, reactor specifications, operating conditions, and test methods are the same as in Example 1.

[0040] (3) After 3 days, the nitrate nitrogen content in the effluent of the reactor can be stably reduced from 40mg / L to below 2.5mg / L, the DOC content is continuously maintained at 2.5-5.5mg / L, and the pH value varies between 6.71-7.33.

Embodiment 3

[0042] (1) The mass ratio of PHBV: sodium bicarbonate: anhydrous ferric chloride: anhydrous manganese chloride = 100: 10: 0.015: 0.070 is used for modification.

[0043] (2) The shaking time is 15s, and the mixed water sample is continuously injected for 36 hours; the rest of the filler treatment, sewage preparation, reactor specifications, operating conditions, and test methods are the same as in Example 1.

[0044] (3) After 3 days, the nitrate nitrogen content in the effluent of the reactor can be stably reduced from 40mg / L to below 2.0mg / L, the DOC content is maintained at 5.0~7.0mg / L, and the pH value varies between 6.95~7.25.

[0045] The measured data and results of the examples can all meet the ideal requirements. Reactor average NO 3 - -N removal rate is above 95%, the highest is 98%; DOC concentration will not affect effluent COD; pH value is in the range suitable for the growth of denitrifying bacteria; film formation speed is 1 day faster than that of PHBV raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com