Preparation method and application of ratio aptamer sensor for streptomycin based on electrochemistry and photoelectrochemistry dual methods

An aptamer sensor, photoelectrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., to achieve the effect of reducing interference, wide linear range and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

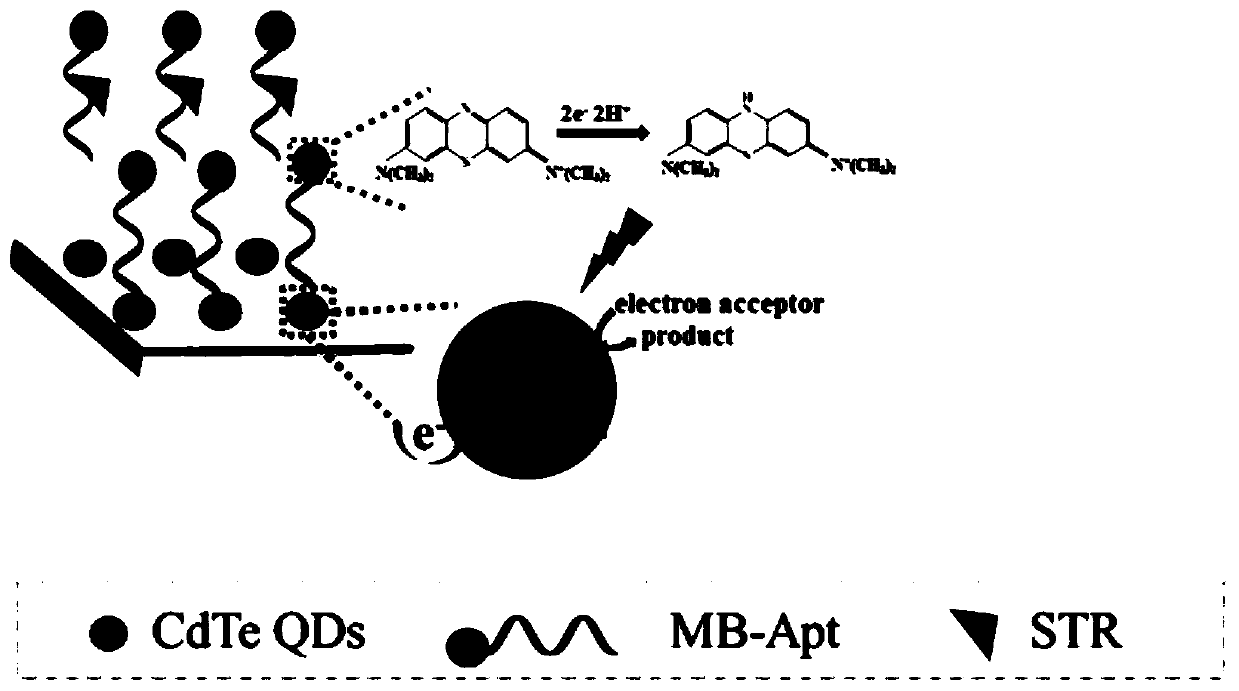

[0028] according to figure 1 Described preparation process:

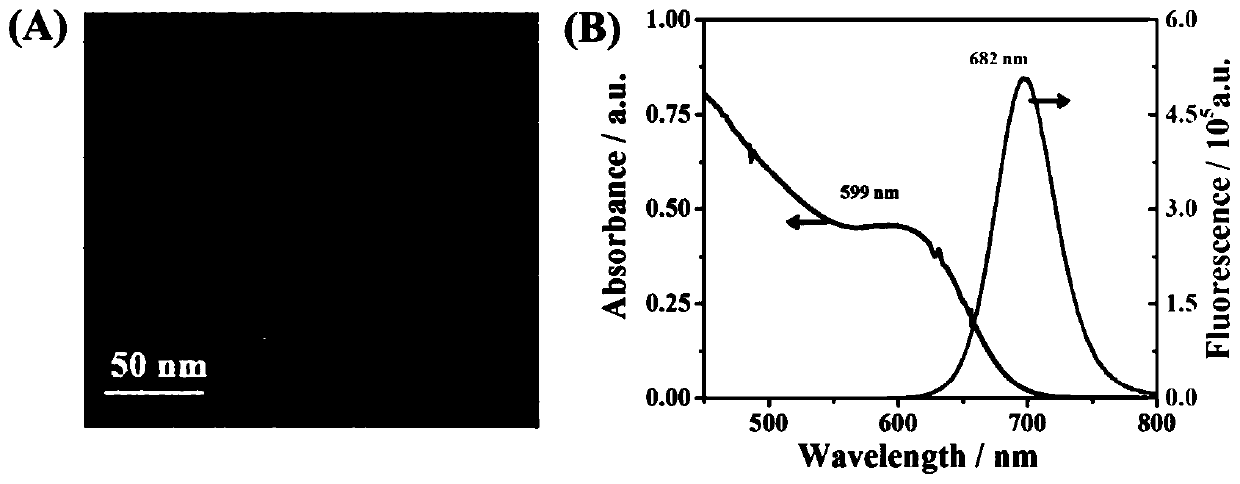

[0029] (1) Preparation of CdTe QDs

[0030] First, weigh 0.04487g of sodium borohydride and 0.0638g of tellurium powder, add 4mL of ultrapure water, pass nitrogen gas to remove oxygen for 15min, obtain a lavender solution, stir in an ice-water bath at 0°C for 8h, and obtain a precursor of sodium tellurium hydride. Then, 0.1142g CdCl 2 2.5H 2 O and 75 μL of mercaptopropionic acid were added to 50 mL of ultrapure water, and stirred for 15 min under nitrogen. The pH of the solution was adjusted to 8.5 with 1 mol / L NaOH solution. Then, quickly pour 2 mL of NaHTe precursor solution. After continuing to stir for 10 min, the mixture was transferred to a three-necked flask and refluxed at 100 °C to obtain CdTe QDs with emission spectra in the near infrared. Finally, the prepared quantum dot solution was mixed with ethanol at a ratio of 1:1, left to stand for 5 minutes, centrifuged, washed, and dispersed in ultrapure w...

Embodiment 2

[0039] (1) Preparation of CdTe QDs

[0040] First, weigh 0.04487g of sodium borohydride and 0.0638g of tellurium powder, add 4mL of ultrapure water, pass nitrogen gas to remove oxygen for 15min, obtain a lavender solution, stir in an ice-water bath at 0°C for 8h, and obtain a precursor of sodium tellurium hydride. Then, 0.1142g CdCl 2 2.5H 2 O and 75 μL of mercaptopropionic acid (MPA) were added to 50 mL of ultrapure water, and stirred for 15 min under nitrogen. The pH of the solution was adjusted to 8.5 with 1 mol / L NaOH solution. Then, quickly pour 2 mL of NaHTe precursor solution. After continuing to stir for 10 min, the mixture was transferred to a three-necked flask and refluxed at 100 °C to obtain CdTe QDs with emission spectra in the near infrared. Finally, the prepared quantum dot solution was mixed with ethanol at a ratio of 1:1, left to stand for 5 minutes, centrifuged, washed, and dispersed in ultrapure water again for later use.

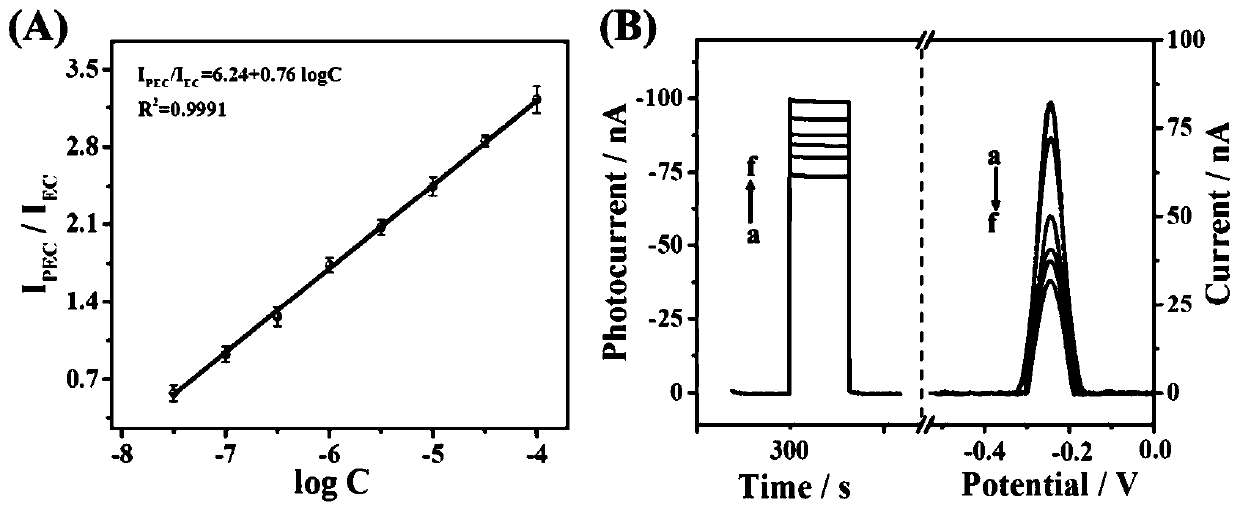

[0041] The CdTe QDs solution ...

Embodiment 3

[0049] (1) Preparation of CdTe QDs

[0050] First, weigh 0.04487g of sodium borohydride and 0.0638g of tellurium powder, add 4mL of ultrapure water, pass nitrogen gas to remove oxygen for 15min, obtain a lavender solution, stir in an ice-water bath at 0°C for 8h, and obtain a precursor of sodium tellurium hydride. Then, 0.1142g CdCl 2 2.5H 2 O and 75 μL of mercaptopropionic acid were added to 50 mL of ultrapure water, and stirred for 15 min under nitrogen. The pH of the solution was adjusted to 8.5 with 1 mol / L NaOH solution. Then, quickly pour 2 mL of NaHTe precursor solution. After continuing to stir for 10 min, the mixture was transferred to a three-necked flask and refluxed at 100 °C to obtain CdTe QDs with emission spectra in the near infrared. Finally, the prepared quantum dot solution was mixed with ethanol at a ratio of 1:1, left to stand for 5 minutes, centrifuged, washed, and dispersed in ultrapure water again for later use.

[0051] The CdTe QDs solution obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com