Modified palladium-carbon catalyst, preparation method and applications thereof

A palladium-carbon catalyst and modifier technology, which is applied in the field of modified palladium-carbon catalysts, can solve problems such as difficult industrialization, low efficiency, and inability to apply industrial production, and achieve the effects of improving stability and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

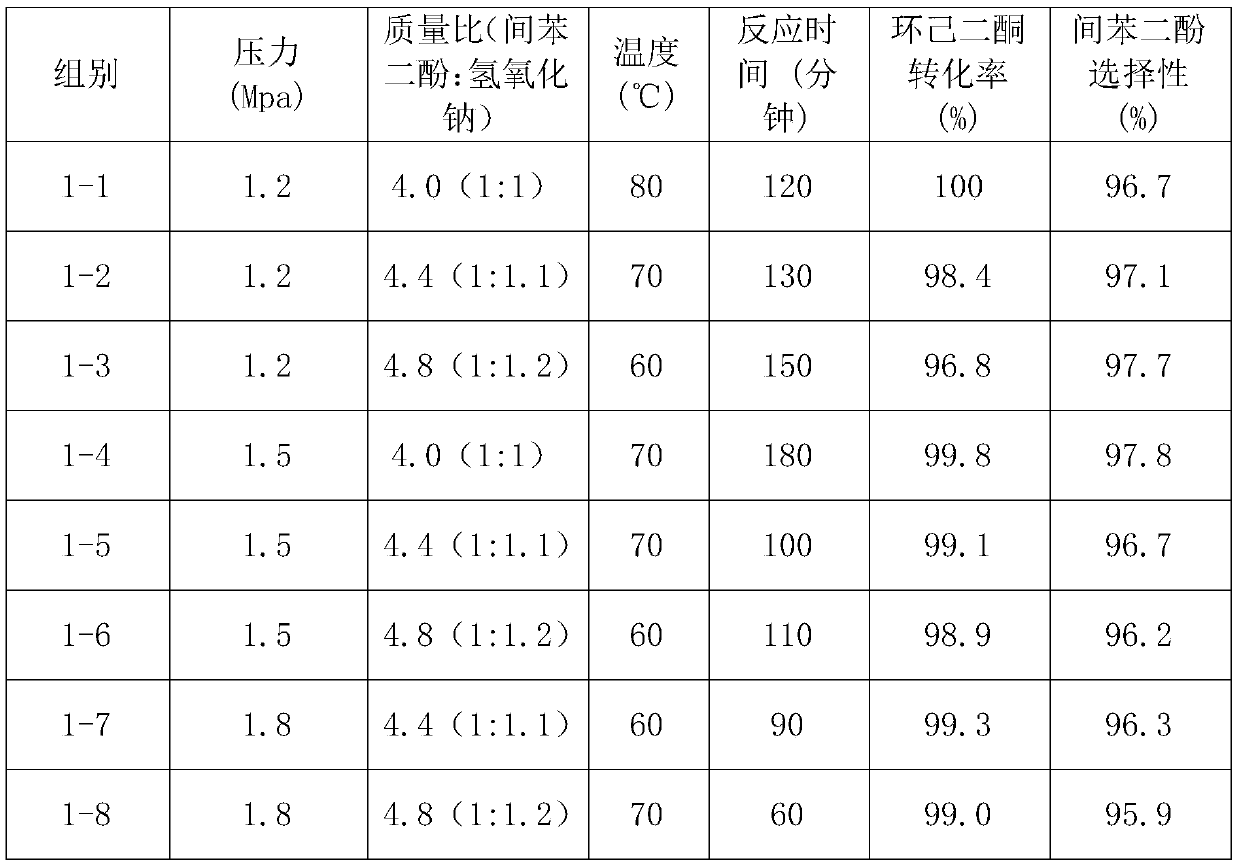

[0059] According to the synthesis method provided by the present invention, 3% Pd / C and PAA are dispersed in methanol, wherein the mass ratio of Pd to PAA is 20:1, and after 8 hours of ultrasonic stirring at room temperature, the modified palladium carbon catalyst is obtained by suction filtration , and washed 3 to 5 times with ultrapure water; put 11.0 g of the substrate 11.0 g of resorcinol alkalized by sodium hydroxide and 120 mL of ultrapure water in a 500-mL reactor, and add 1.0 g of modified palladium Carbon catalyst (wet product, water content 60%, the molar ratio of substrate to Pd is about 830:1), the air in the reaction is replaced with hydrogen for 3 times, and the test is carried out at 60-80°C and 1.2-1.8MPa . The experimental data are shown in Table 1.

[0060] Table 1 prepares the result of 1,3-cyclohexanedione by the method described in Example 1 of the present invention under different reaction conditions

[0061]

[0062] The results of Example 1 show th...

Embodiment 2

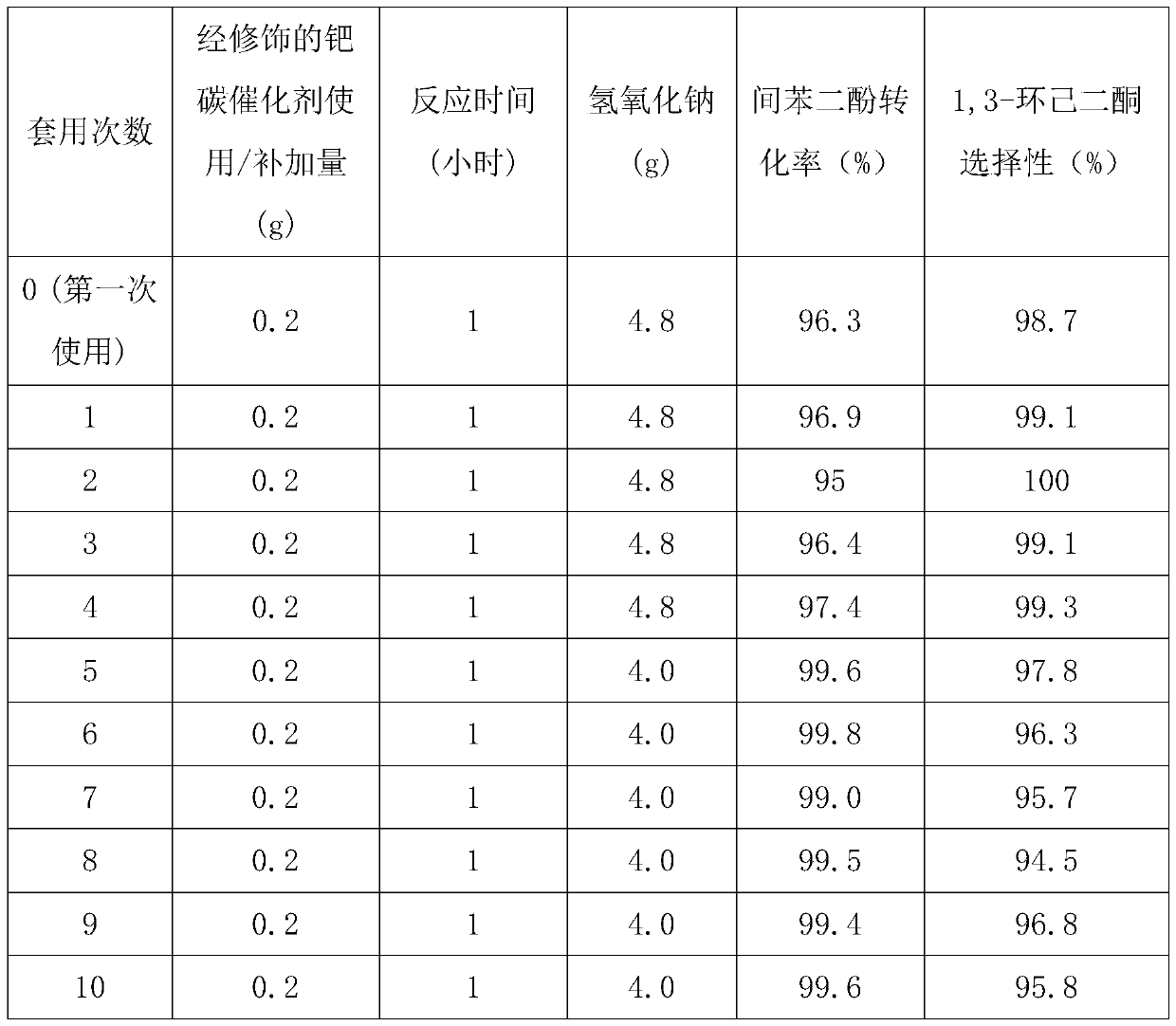

[0064] According to the synthesis method provided by the present invention, 3% Pd / C and PVA are dispersed in ethanol, wherein the mass ratio of Pd to PVA is 10:1, and after ultrasonic stirring at room temperature for 6 hours, suction filtration obtains the modified palladium carbon catalyst , and washed 3 to 5 times with ultrapure water; put 11.0 g of the substrate 11.0 g of resorcinol alkalized by sodium hydroxide and 120 mL of ultrapure water in a 500-mL reactor, and add 1.0 g of modified palladium Carbon catalyst (wet product, water content 60%, substrate to Pd molar ratio is about 830:1), replace the air in the reaction with hydrogen for 3 times, test at 80°C and 1.8MPa, and react when applied mechanically Same conditions. The experimental data are shown in Table 2.

[0065] Table 2 prepares the result of 1,3-cyclohexanedione by the method described in the embodiment of the present invention 2

[0066]

[0067] The result of embodiment 2 shows that the 3%Pd / C of PVA m...

Embodiment 3

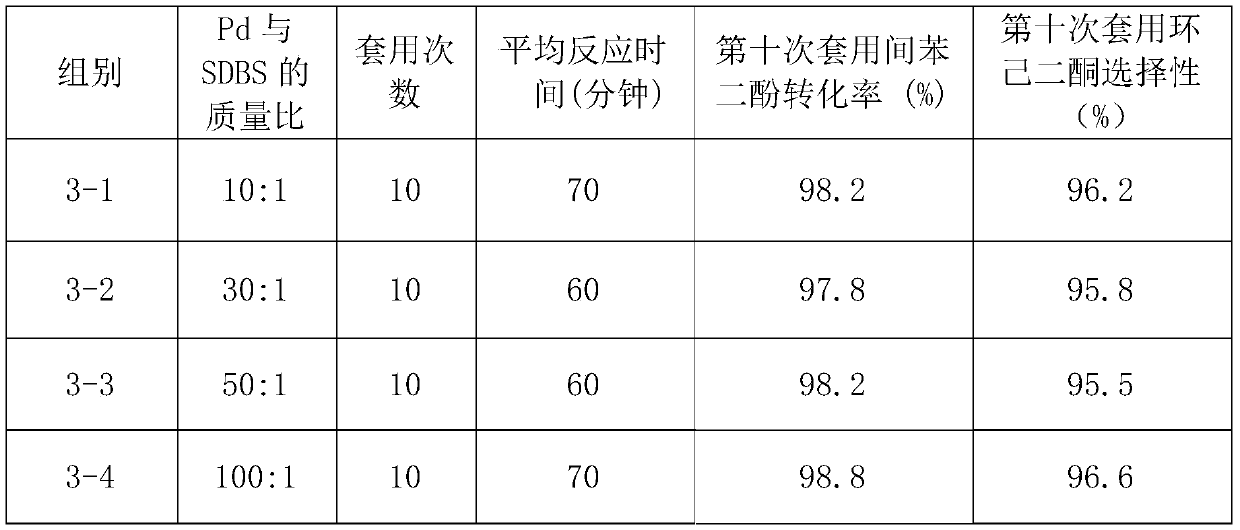

[0069] According to the synthesis method provided by the present invention, 3% Pd / C and different quality SDBS are dispersed in DMF, and after ultrasonic stirring at room temperature for 10 hours, the modified palladium carbon catalyst is obtained by suction filtration, and washed with ultrapure water for 3- 5 times; 11.0 g of the substrate 11.0 g of resorcinol alkalized by sodium hydroxide and 120 mL of ultrapure water were placed in a 500-mL reaction kettle, and 1.0 g of modified palladium carbon catalyst (wet product, water content 60 %, the substrate to Pd molar ratio is about 830:1), the air in the reaction is replaced with hydrogen 3 times, and the test is carried out at 80°C and 1.8MPa, and the reaction conditions are the same when applied mechanically. The experimental data are shown in Table 3.

[0070] Table 3 prepares the result of 13-cyclohexanedione by the method described in the embodiment of the present invention 3

[0071]

[0072] The results of Example 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com