A kind of breeding wastewater treatment process

A technology for breeding wastewater and treatment process, which is applied in the field of livestock and poultry breeding wastewater treatment, can solve the problems of complex immobilized microorganism process, high time cost and high technical content, and can solve difficult separation and cell loss, save clean water, and clean the ground. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

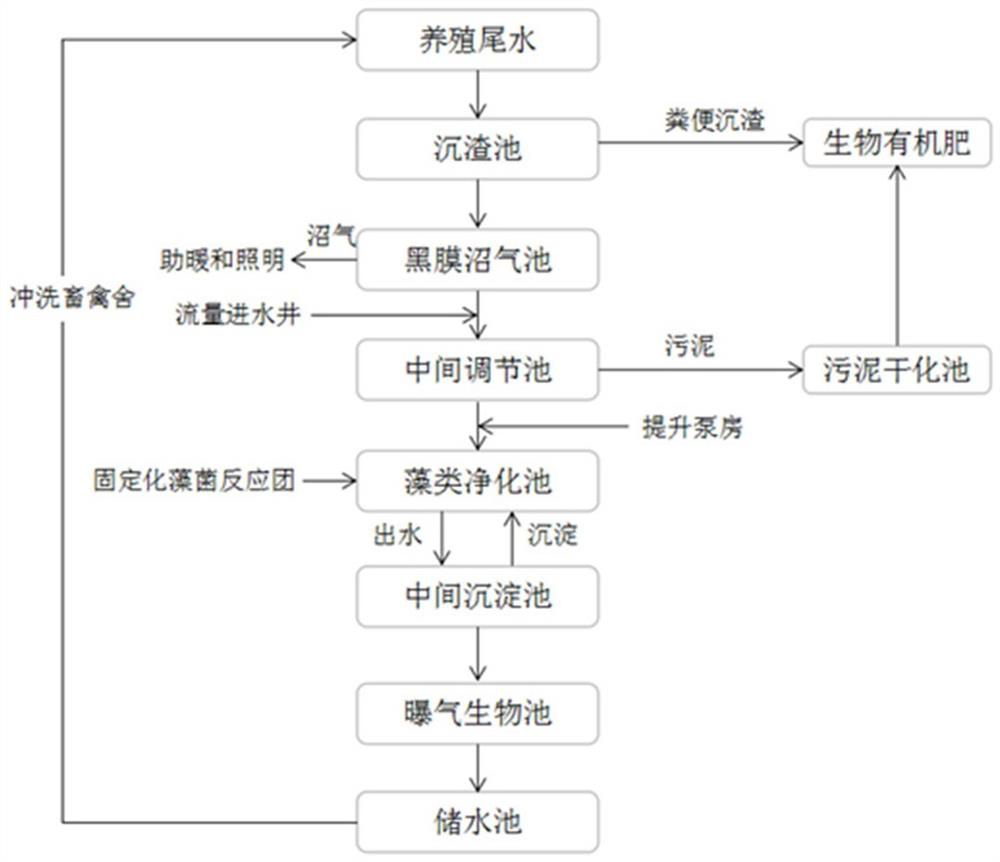

[0032] see figure 1 and figure 2 , a breeding wastewater treatment process, specifically comprising the steps of:

[0033] S1. The aquaculture wastewater is collected into the sediment tank through the sewage pipe, and the solid fecal residue is removed through the solid-liquid separator, and the liquid enters the black film biogas digester;

[0034] S2. Measure the incoming water entering the black film biogas digester through the influent flow well, and distribute the water to the black film biogas digester to remove organic matter in the water and generate biogas. The generated biogas is used for boiler heating and lighting after desulfurization and decarbonization treatment;

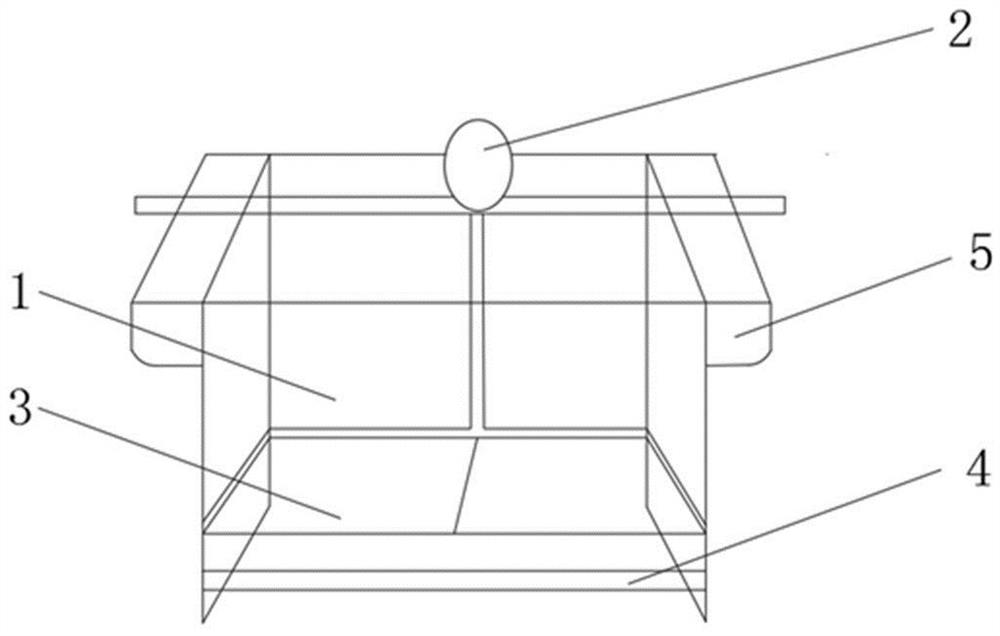

[0035] S3. The biogas slurry produced by the black film biogas digester is distributed to the algae purification tank through the lifting pump room, and the immo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com