Titanium slag cement, preparation method and application thereof

A technology for cement and titanium slag, applied in cement production and other directions, can solve the problems of high production cost of ordinary Portland cement and low resource utilization rate of titanium tailing slag, so as to improve resource utilization rate, low cost and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

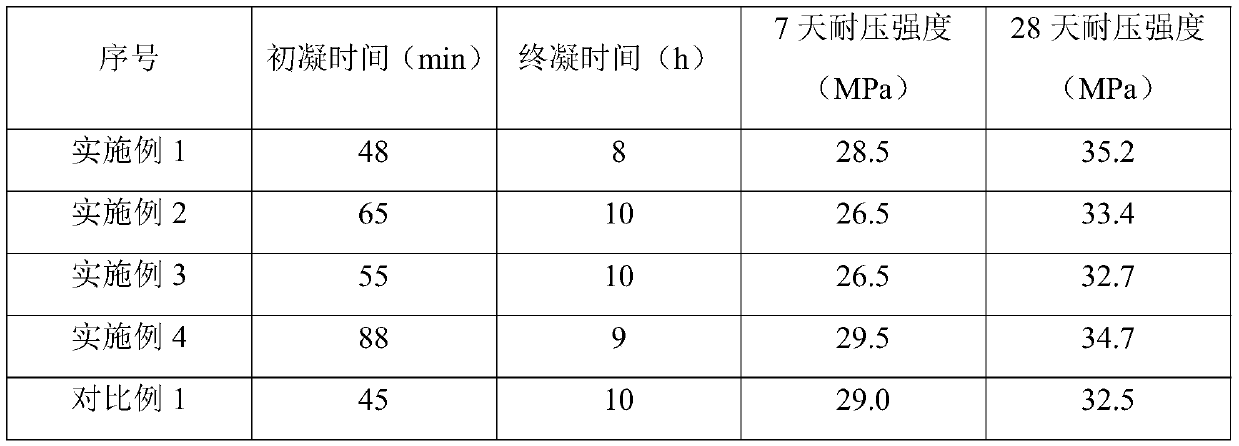

Examples

preparation example Construction

[0028] The second aspect of the present invention provides the preparation method of above-mentioned titanium slag cement, described method comprises the following steps:

[0029] (1) dry-blending the titanium extraction tailings, activator, strengthening agent, auxiliary strengthening agent and early strength agent to obtain a mixture;

[0030] (2) Aging the mixture described in step (1) and sealing it for packaging.

[0031] Preferably, in step (1), before the dry blending, it also includes ball milling and activating the titanium extraction tailings, and pulverizing the activator, strengthening agent, auxiliary strengthening agent and early strength agent. The titanium slag fine powder is obtained after the titanium slag is treated by a ball milling process, and the specific surface area of the titanium slag fine powder is 400m 2 / kg or more, preferably 400-500m 2 / kg, has good pozzolanic activity; after the activator, reinforcing agent, auxiliary reinforcing agent and ...

Embodiment 1

[0043] 80 parts by weight of titanium extraction tailings, 10 parts by weight of desulfurized gypsum, 5 parts by weight of slaked lime, 3 parts by weight of vitriol, 2 parts by weight of calcium chloride and 1 part by weight of magnesium chloride were uniformly mixed by ball milling dry mixing process to obtain a mixture, and then Aging the mixture for 24 hours and sealing the package to obtain titanium slag cement S1, the properties of which are shown in Table 2. Wherein, before the dry blending, it also includes ball milling and activating the titanium extraction tailings, and pulverizing the exciter, strengthening agent, auxiliary strengthening agent and early strengthening agent. After ball milling, the obtained titanium slag fine powder has a specific surface area of 405m 2 / kg, after pulverizing, the particle size of the obtained slaked lime, green vitriol, calcium chloride and magnesium chloride fine powder is below 250 mesh, and the particle size of the obtained desu...

Embodiment 2

[0045] 50 parts by weight of titanium extraction tailings, 20 parts by weight of desulfurized gypsum, 20 parts by weight of slaked lime, 5 parts by weight of vitriol and 5 parts by weight of calcium chloride are uniformly mixed by ball milling dry mixing process to obtain a mixture, and then the mixture is aged After 24 hours, sealed and packaged, titanium slag cement S2 can be obtained, and its properties are shown in Table 2. Wherein, before the dry blending, it also includes ball milling and activating the titanium extraction tailings, and pulverizing the exciter, strengthening agent, auxiliary strengthening agent and early strengthening agent. After ball milling, the obtained titanium slag fine powder has a specific surface area of 450m 2 / kg, after pulverizing, the particle size of the obtained slaked lime, green vitriol and calcium chloride fine powder is below 250 mesh, and the particle size of the obtained desulfurized gypsum fine powder is below 200 mesh; of.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com