Channelized fluor alkaline production method capable of improving reaction process selectivity

A technology of reaction process and fluorinated alkanes, which is applied in chemical instruments and methods, chemical/physical processes, organic chemistry, etc. It can solve the problems of poor reaction selectivity and inability to realize graded reaction control of reaction raw materials, so as to reduce corrosion and temperature , the effect of high reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

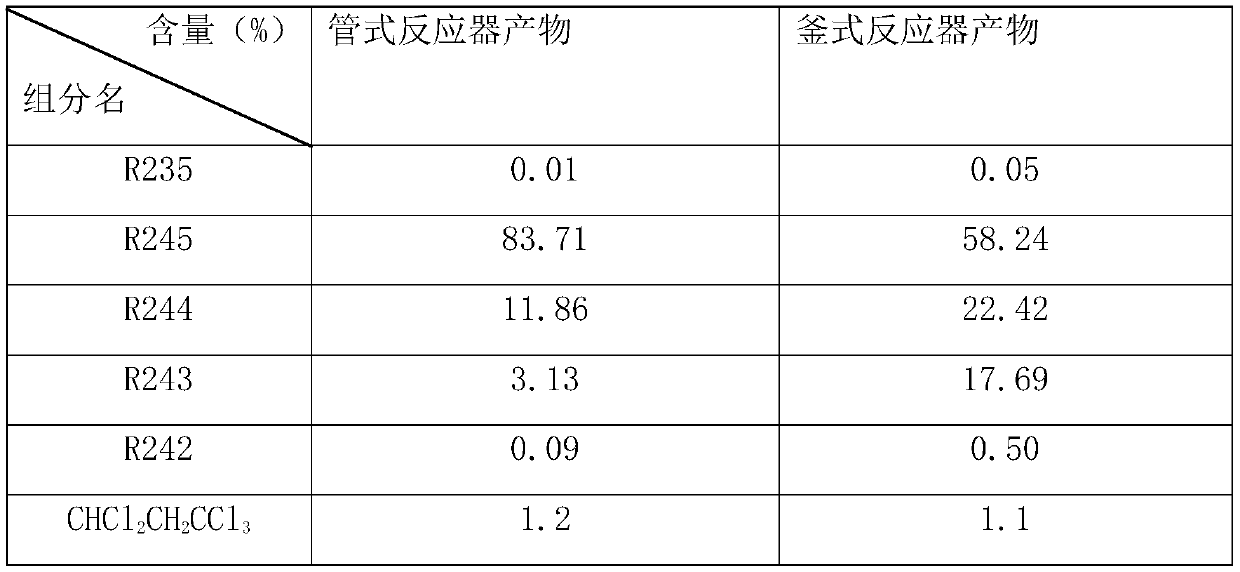

[0039] A method for pipelined production of fluorinated alkanes that improves the selectivity of the reaction process. In the presence of a fluorinated catalyst, a fluorinated substrate and a fluorinated agent are reacted in a pipelined reactor to obtain the fluorinated alkanes. The fluorinated alkanes have the following general formula: CnH2n+2-x-yClxFy, wherein, n is an integer of 1 to 3; the fluorinating agent is selected from hydrogen fluoride, potassium fluoride, mercury difluoride, and cobalt trifluoride One or more of the fluorinated substrates having the general formula C n h 2n+2-x Cl x , wherein, n is an integer of 1 to 3, x<6, and the fluorination catalyst is selected from one of antimony pentachloride, antimony chlorofluoride, tin tetrachloride, sulfur tetrafluoride and titanium tetrachloride or more; the pipelined reactor includes at least two heating section groups, the heating section group includes at least one heating section, and the heating section groups ...

Embodiment 1

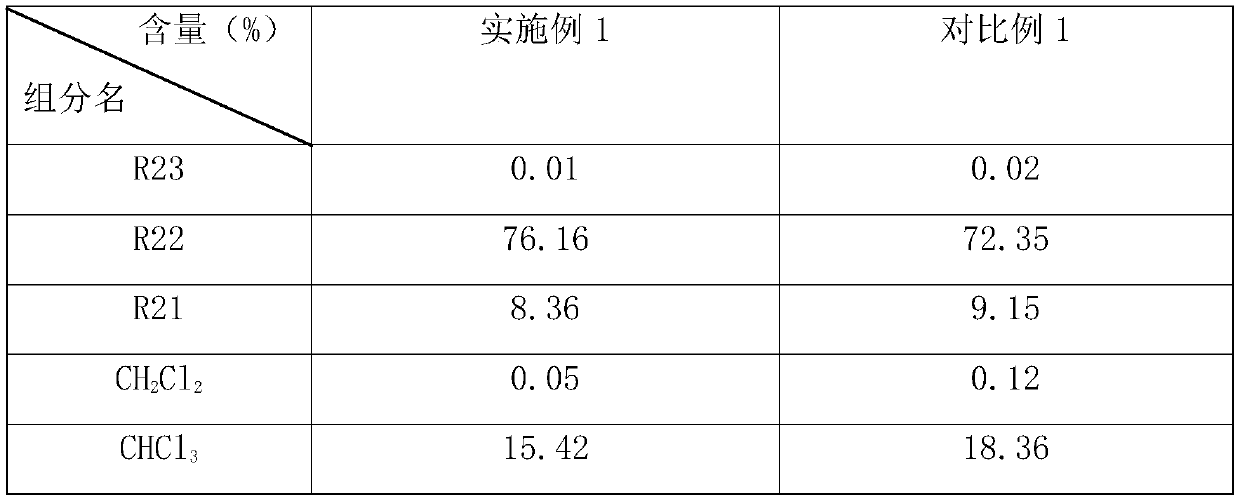

[0060] In Example 1, it is a method for pipelined production of fluorinated alkanes to improve the selectivity of the reaction process. The fluorinated alkanes are specifically difluorochloromethane. Other relevant technical features are not listed in Example 1. Refer to the preparation example.

[0061] In this example, after mixing chloroform and antimony pentachloride at a mass ratio of 10:1, preheat to 50°C at a flow rate of 2m / s, and the fluorinating agent is a mixture of hydrogen fluoride and cobalt trifluoride to The flow rate of 1m / s is preheated to 70°C. After being mixed by a static mixer, it enters a tubular reactor with a volume of 0.2L. The tubular reactor has two heating sections. The temperature of the first heating section is controlled at 80°C. Inject pressurized gas nitrogen to control the pressure of fluorination reaction to 1.0MPa. Hydrogen fluoride and chloroform in the raw material flow are catalyzed by the fluorination catalyst, and the fluorination react...

Embodiment 2

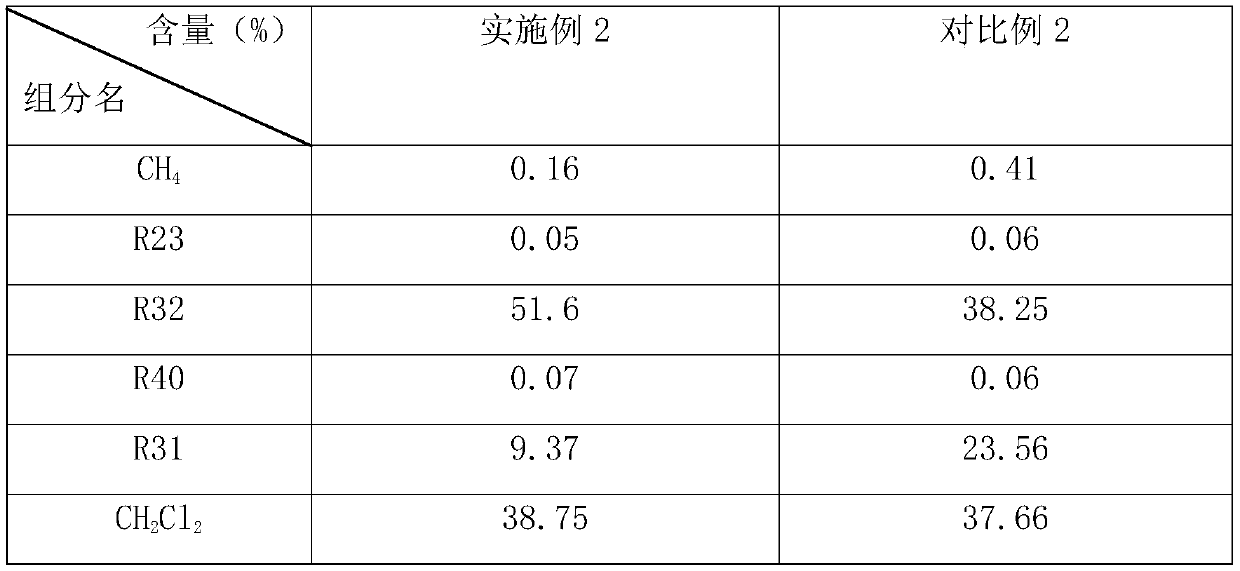

[0068] In Example 2, it is a method for pipelined production of fluorinated alkanes to improve the selectivity of the reaction process. The fluorinated alkanes are specifically difluoromethane. Other relevant technical features are not listed in Example 1. Refer to the preparation example.

[0069] After mixing dichloromethane and antimony pentachloride at a mass ratio of 10:1, preheat to 70°C at a flow rate of 2m / s, preheat to 90°C at a flow rate of 1m / s for hydrogen fluoride, mix them through a static mixer, and enter In a tubular reactor with a volume of 0.2L, the tubular reactor has two heating sections, the temperature of the first heating section is controlled at 100°C, and the pressurized gas nitrogen is filled to control the fluorination reaction pressure to 1.5MPa. Hydrogen fluoride and dichloromethane are catalyzed by a fluorination catalyst, and the fluorination reaction is carried out in a tubular reactor. The resulting reaction liquid includes the product of the fl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap