Methylation method of amine

A methylation and organic amine technology, applied in the field of organic synthesis, can solve the problems of potential safety hazards and limitations of highly toxic reagents, and achieve the effects of high selectivity and yield, more substrates, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of example 1, composite catalyst, carries out following steps successively

[0036] ①. Weigh 10g of Ni-Al-Mo-Cd-Fe alloy powder into a beaker, the mass fraction of Ni in the alloy powder is 60%, the mass fraction of Al is 38.67%, the mass fraction of Mo is 0.67%, and the mass fraction of Cd is 0.33%, The mass fraction of Fe is 0.33%; then 50 mL of sodium hydroxide solution with a concentration of 5 mol / L is added dropwise to the above alloy powder (dropping time is 20 min), and kept in an ice-water bath (about 0° C.) during the dropping process And magnetic stirring at 120r / min, after the dropwise addition, continue to stir for 30min (in an ice-water bath, 120r / min).

[0037] Explanation: According to the mass fraction notified above, the alloy powder as raw material can be easily obtained according to the known technology.

[0038] 2. Post-processing the reaction product obtained after the stirring reaction, the post-processing is: filtering the...

Embodiment 1

[0041] Embodiment 1, a kind of production method of tetramethylethylenediamine, comprises the steps:

[0042] 1) Add 12g (0.2mol) of ethylenediamine, 25.8g (0.86mol) of paraformaldehyde, and 36g of methanol into the autoclave, then add 0.84g of composite catalyst, replace with nitrogen for 3 times, and feed hydrogen into the autoclave The pressure is controlled at 1.5MPa, the reaction temperature is 50°C, and the reaction time is 9h.

[0043] Note: During the whole reaction process, it is necessary to control the pressure in the autoclave to always be 1.5Mpa by adjusting the amount of hydrogen.

[0044] 2), after the reaction is finished, cool to room temperature, filter, and the filter cake obtained by filtering is washed with deionized water to neutrality, and then stored in water as a recyclable composite catalyst. The obtained filtrate was subjected to atmospheric distillation, and the fraction at 120°C was collected to obtain the product—tetramethylethylenediamine, with ...

Embodiment 2~ Embodiment 9

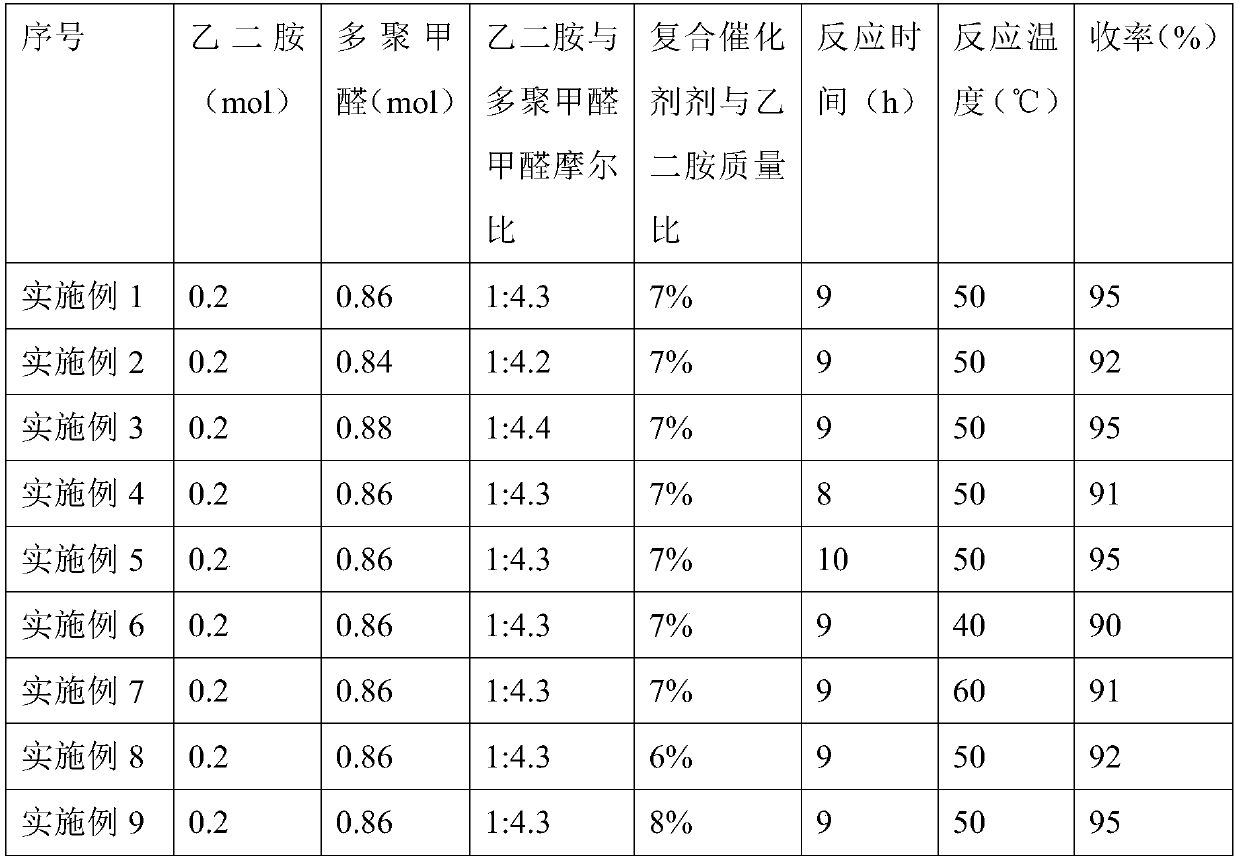

[0046] Change the molar ratio of ethylenediamine and paraformaldehyde in Example 1, catalyst consumption, reaction time and reaction temperature, all the other are equal to Example 1, respectively obtain Example 2~Example 9, the product obtained---Tetramethyl The yield of ethylenediamine is shown in Table 1 (the purity is all about 99%).

[0047] Table 1

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com