Polyethylene resin for large-diameter winding pipe and industrial production method thereof

A polyethylene resin and production method technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems such as insufficient rigidity, smoke and odor, and high oligomer content, and achieve Improve processing speed, good mechanical properties, high melt index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of high-density polyethylene

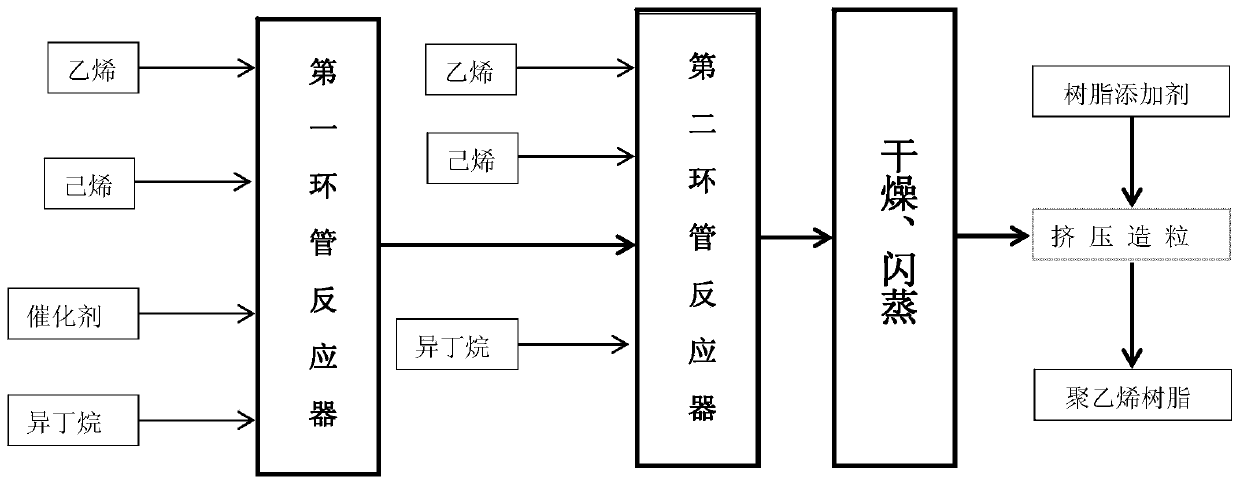

[0042] The polymerization reaction is carried out on a double-loop slurry process unit. The process unit mainly includes catalyst activation unit, material refining unit, catalyst feeding unit (the catalyst feeding unit is used to prepare the activated chromium-based catalyst and pure isobutane according to a certain concentration) and the polymerization reaction unit (No. first reactor and second reactor). The process steps are as follows:

[0043] (1) Catalyst activation

[0044] Using an externally purchased chromium-based catalyst containing trivalent chromium supported by inert silica (for example, trivalent chromium salts such as chromium acetate or chromium acetylacetonate, these chromium salts are loaded on a porous amorphous silicon carrier), the catalyst The mass fraction of chromium in the medium is 1% [=0.192mmol (Cr) / g (catalyst)]±0.1%.

[0045] The chromium-based catalyst is specifically activated in an act...

Embodiment 2

[0072] Different from the process parameter control in Example 1: the reaction temperature of the two reactors, the concentration ratio of the comonomer hexene to ethylene are mainly changed.

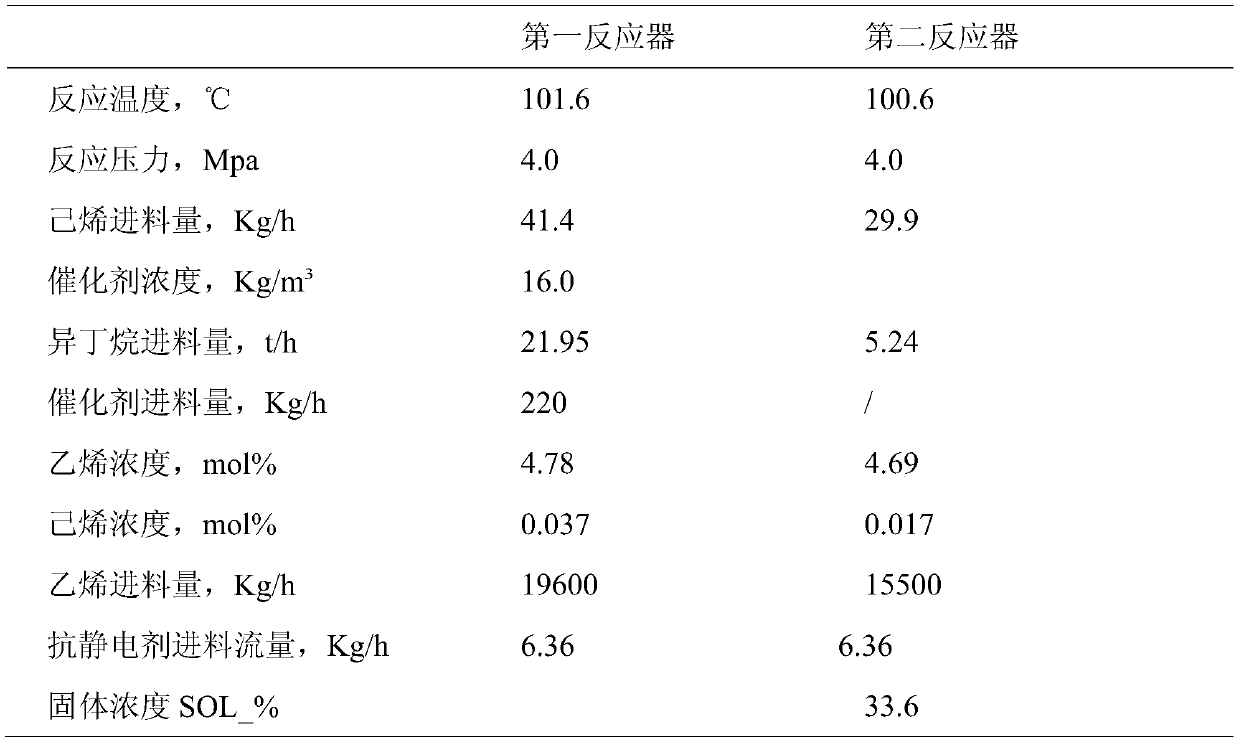

[0073] The specific production process control parameters of the two reactors are shown in Table 5, the residence time of the first reactor is 2 hours, and the residence time of the second reactor is 0.7 hours.

[0074] The reaction condition of the polyethylene powder that table 5. embodiment 2 produces

[0075]

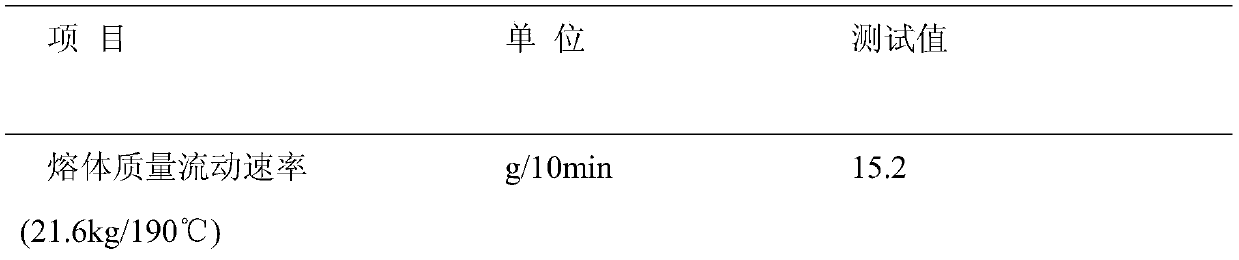

[0076] When the reaction temperature of the first reactor reaches 101°C and the temperature of the second reactor reaches 100°C, the melt mass flow rate (21.6Kg / 190°C) of polyethylene powder and pellets can reach 13-15g / Within 10 minutes; the amount of hexene in the first reactor is 38.5Kg / h, and the amount of hexene in the second reactor is 28.7Kg / h, so that the density of polyethylene pellets can reach 0.954-0.958g / cm 3 within range.

[0077] The high-density polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com