Method for preparing titanium-rich material for fluidizing chlorination from high-calcium-magnesium low-grade titanium slag

A low-grade titanium, boiling chlorination technology, applied in metallurgy and chemical industry, can solve problems such as difficult industrial amplification, difficult upgrading, and inability to upgrade, to improve reduction kinetics, solve difficult or impossible to upgrade, and the recovery rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 200g of 40-200 mesh typical Panxi titanium slag, put it into a quartz reactor, and oxidize it at an oxidation temperature of 950°C, an oxygen concentration of 6vol.%, and an oxygen flow rate of 150L / h for 1h. After reaching the oxidation time, purge with nitrogen , then feed coke oven gas, reduce at 800°C for 1.5h, gas velocity is 130-150L / h, after the set time, feed nitrogen to cool to room temperature, then reduce titanium slag and hydrochloric acid in the digestion tank Mix evenly for acid leaching treatment, the concentration of hydrochloric acid is 20%, the liquid-solid ratio (ml:g)=2:1, the acid leaching temperature is 135°C, the acid leaching time is 6h, and the rotation speed of the digestion tank is 20r / min.

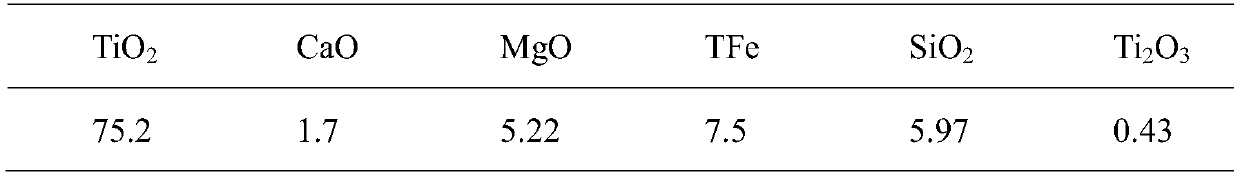

[0046] After the acid leaching treatment, the liquid-solid separation is carried out, and the washing water is washed with pure water until the washing water is clear, and finally dried in an oven at 105 ° C for 2 hours to obtain TiO 2 Grade is abou...

Embodiment 2

[0048] Weigh 200g of typical Panxi titanium slag of 40-200 mesh, put it into a quartz reactor, and oxidize it at an oxidation temperature of 1000°C, an oxygen concentration of 6vol.%, and an oxygen flow rate of 150L / h for 1.5h. After reaching the oxidation time, blow it with nitrogen. Scanning, the microscopic morphology of the oxidation product is as follows figure 1 As shown, then pass in coke oven gas, reduce at 850°C for 1.5h, the gas velocity is 130-150L / h, after the set time, pass in nitrogen to cool to room temperature, and then reduce the titanium slag in the digestion tank Mix with hydrochloric acid evenly for acid leaching treatment, the concentration of hydrochloric acid is 20%, the liquid-solid ratio (ml:g) = 2:1, the acid leaching temperature is 145°C, the acid leaching time is 6h, and the speed of the digestion tank is 20r / min.

[0049] After the acid leaching treatment, the liquid-solid separation is carried out, and the washing water is washed with pure water u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com