Method for recycling tungsten carbide and cobalt sulfate from tungsten carbide waste

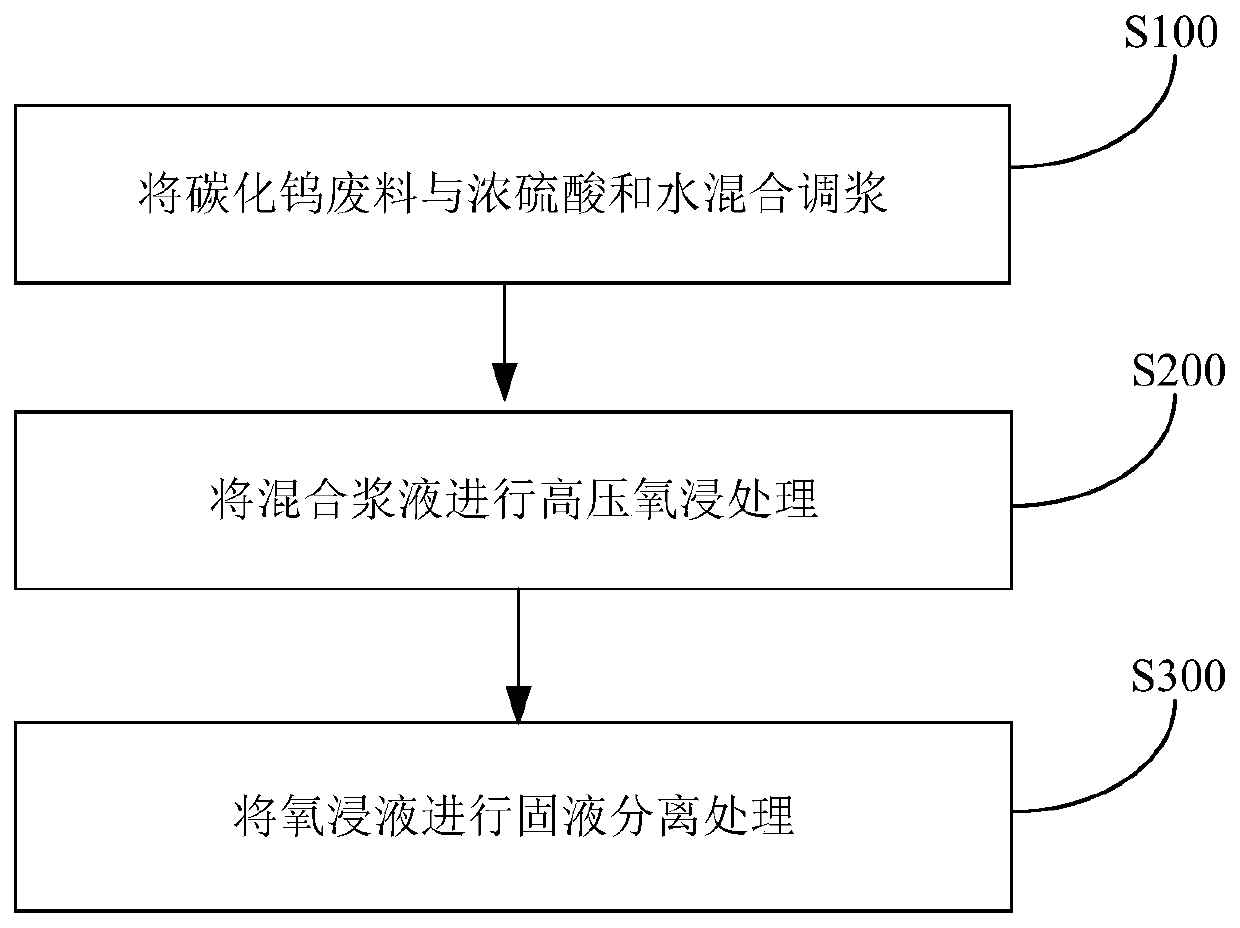

A technology of tungsten carbide and tungsten waste, applied in the direction of cobalt sulfate, carbide, tungsten/molybdenum carbide, etc., can solve the problems of low leaching rate, low leaching rate, long leaching time, etc., and achieve low input cost and method. Simple operation and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Get 300kg of tungsten carbide waste (the mass content of tungsten is 3%, the mass content of cobalt is 20%, the mass content of oil is 5%, and the mass content of water is 3%), and the tungsten carbide waste is dried at a drying temperature of 150 °C, drying time 24h, to obtain a dried material with an oil content of 0.2wt% and a moisture content of 0.1wt%;

[0039] (2) The dried material is crushed by crushing equipment, passed through a 150-mesh screen, and the crushed material with a particle size of not less than 150 mesh is obtained;

[0040] (3) Add water to the crushed material to adjust the slurry, add concentrated sulfuric acid to the slurry, the amount of concentrated sulfuric acid is 1.2 times the theoretical value, and then add water to adjust the solid-liquid ratio to 1:10, and then send the obtained slurry into high pressure oxygen The high-pressure oxygen immersion reaction is carried out in the immersion equipment. The reaction conditions include the...

Embodiment 2

[0042] (1) Get 500kg of tungsten carbide waste (the mass content of tungsten is 95%, the mass content of cobalt is 3%, the mass content of oil is 4%, and the mass content of water is 5%), and the tungsten carbide waste is dried at a drying temperature of 300 °C, drying time 1h, to obtain a dried material with an oil content of 0.3wt% and a moisture content of 0.2wt%;

[0043] (2) The dried material is crushed by crushing equipment, passed through a 100-mesh screen, and the crushed material with a particle size of not less than 100 mesh is obtained;

[0044] (3) Add water to the crushed material to adjust the slurry, add concentrated sulfuric acid to the slurry, the amount of concentrated sulfuric acid is 3.0 times the theoretical value, and then add water to adjust the solid-liquid ratio to 1:3, and then send the obtained slurry into the high pressure oxygen The high-pressure oxygen immersion reaction is carried out in the immersion equipment. The reaction conditions include r...

Embodiment 3

[0046] (1) Get 400kg of tungsten carbide waste (the mass content of tungsten is 80%, the mass content of cobalt is 5%, the mass content of oil is 3%, and the mass content of water is 7%), and the tungsten carbide waste is dried at a drying temperature of 250 °C, drying time 8h, to obtain a dried material with an oil content of 0.2wt% and a moisture content of 0.2wt%;

[0047] (2) The dried material is crushed by crushing equipment, passed through a 60-mesh screen, and the crushed material with a particle size of not less than 60 mesh is obtained;

[0048] (3) Add water to the crushed material to adjust the slurry, add concentrated sulfuric acid to the slurry, the amount of concentrated sulfuric acid is 2.0 times the theoretical value, and then add water to adjust the solid-liquid ratio to 1:4, and then send the obtained slurry into the high pressure oxygen The high-pressure oxygen immersion reaction is carried out in the immersion equipment. The reaction conditions include the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com