Acicular ha/pblg porous composite microcarrier material for bone tissue engineering and preparation method thereof

A technology of bone tissue engineering and microcarriers, applied in tissue regeneration, prostheses, pharmaceutical formulations, etc., can solve the problems of high preparation process requirements, shielding of biological properties of inorganic particles, uneven dispersion of inorganic substances, etc., to promote osteogenic differentiation. , good bone regeneration effect, beneficial effect of early adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

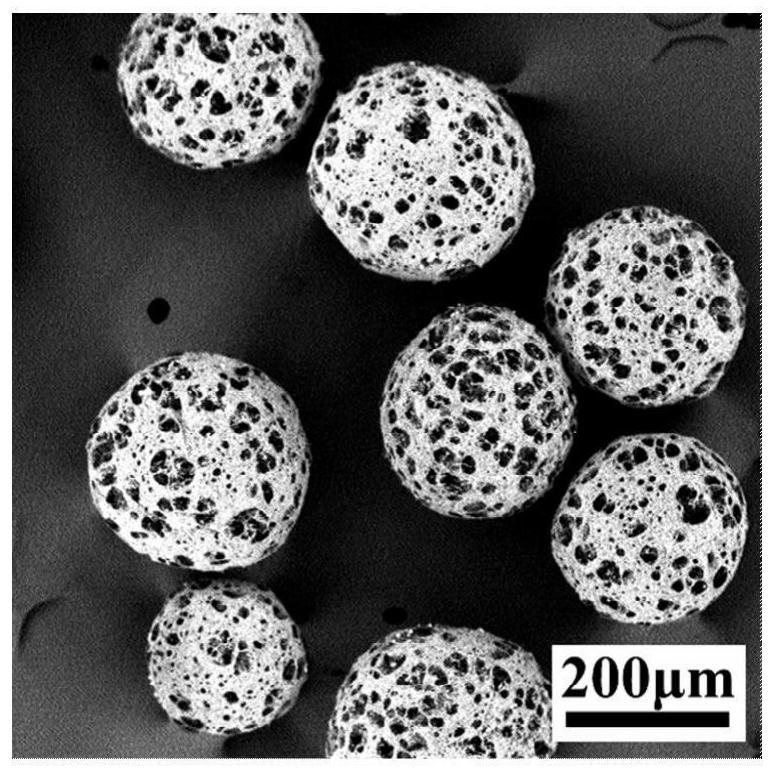

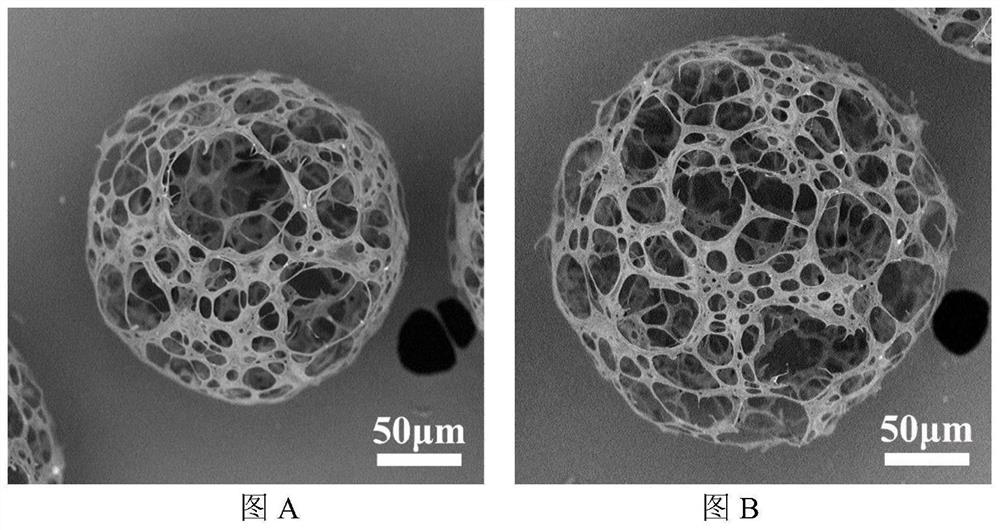

[0039] In the present embodiment, a kind of preparation method of PBLG porous microcarrier comprises the steps:

[0040] a. Poly benzyl L-glutamate (PBLG) solution preparation: in N 2 Under the atmosphere, use triethylamine as the initiator to initiate ring-opening polymerization of BLG-NCA, and obtain PBLG by precipitation with absolute ethanol; weigh 0.1-0.2g PBLG into a 25mL beaker, and then measure 10-25mL dichloromethane with a graduated cylinder Add in the beaker, stir until PBLG dissolves completely, obtain transparent solution, be poly-benzyl L-glutamate (PBLG) solution;

[0041] b. preparation of polyvinyl alcohol (PVA) aqueous solution: the PVA solid is dissolved in deionized water to obtain a PVA solution with a mass percent concentration of 0.8 to 1.0%;

[0042] c. Preparation of gelatin solution: using gelatin as a porogen, dissolving 4-6g of gelatin in 50-60mL of deionized water, stirring at 37°C until the solution is transparent and clear to obtain a gelatin so...

Embodiment 2

[0062] This embodiment is basically the same as Embodiment 1, especially in that:

[0063] In this example, the preparation method of the PBLG porous microcarrier and the preparation method of the carboxylated modified PBLG porous microcarrier are the same as those in Example 1.

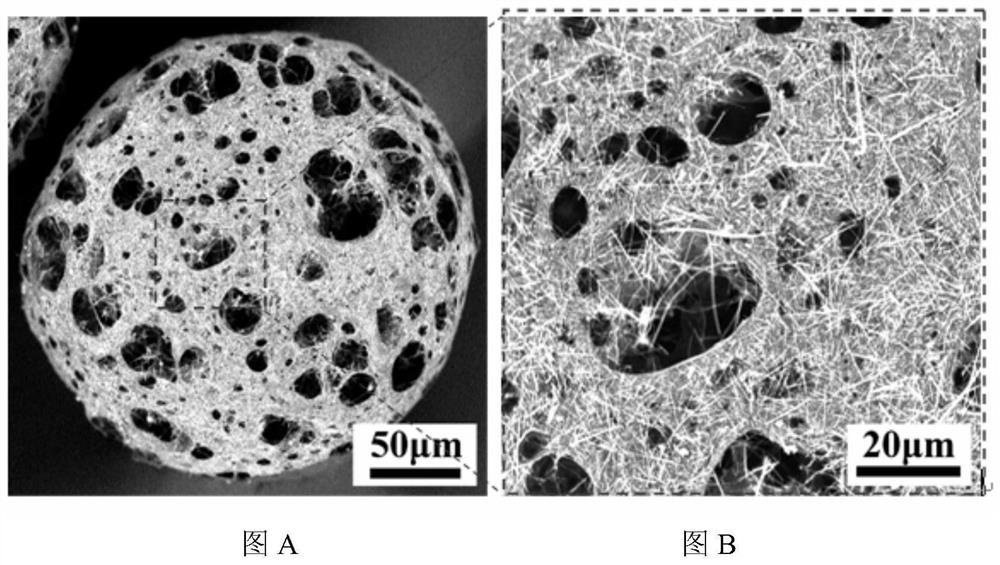

[0064] In this embodiment, a method for preparing needle-shaped HA / PBLG porous composite microcarrier material for bone tissue engineering comprises the following steps:

[0065] (1) Add 100 mL of 0.25 mol / L CaCl to a 500 mL beaker 2 solution, and then add the PBLG porous microcarrier after the surface carboxylation modification of 1mL volume, obtain the first mixed liquid system;

[0066] (2) heating up to 70-80°C, and maintaining the speed of 150r / min all the time, mechanically stirring the first mixed liquid system prepared in the step (1) for 30-40min;

[0067] (3) Add 100 mL of 0.015 mol / L NaH dropwise to the first mixed liquid system that has been stirred in the step (2) at a rate of 2 to 4 m...

Embodiment 3

[0073] This embodiment is basically the same as the previous embodiment, and the special features are:

[0074] In this example, the preparation method of the PBLG porous microcarrier and the preparation method of the carboxylated modified PBLG porous microcarrier are the same as those in Example 1.

[0075] In this embodiment, a method for preparing needle-shaped HA / PBLG porous composite microcarrier material for bone tissue engineering comprises the following steps:

[0076] (1) Add 100mL of 0.05mol / L CaCl to a 500mL beaker 2 solution, and then add the PBLG porous microcarrier after the surface carboxylation modification of 1mL volume, obtain the first mixed liquid system;

[0077] (2) heating up to 70-80°C, and maintaining the speed of 150r / min all the time, mechanically stirring the first mixed liquid system prepared in the step (1) for 30-40min;

[0078] (3) Add 100 mL of 0.03 mol / L NaH dropwise to the first mixed liquid system that has been stirred in the step (2) at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com