Method for synthesizing and forming UTSA-280 adsorbent materials on large scale

A technology of UTSA-280 and synthesis method, which is applied in the field of preparation of UTSA-280 adsorbent material, can solve the problems of affecting the economic benefit of enterprises, large process energy consumption, etc., and achieve the effect of convenient and accurate addition amount control and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

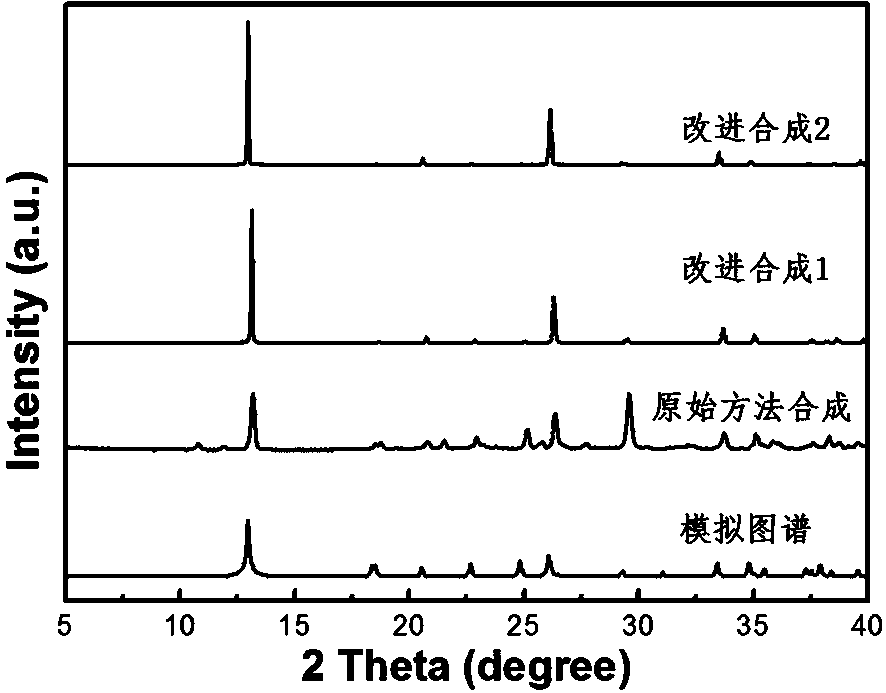

[0031] Through the improvement of the prior art method, switch to NH 3 ·H 2 O promotes the dissolution of squaraine in the early stage, helps to form a high-concentration and uniform squaraine solution, and forms UTSA-280 with high crystallinity (improved synthesis 1):

[0032] ①Add 10.944g squaraine to 200mL distilled water and stir well to form a supersaturated squaraine solution.

[0033] ②Add 12mL NH 3 ·H 2 O (25%), add while stirring. Now, 95% of squaraine can be dissolved to form a high-concentration squaraine solution of 48g / L.

[0034] ③Add 200mL of 22.656g calcium nitrate tetrahydrate solution to the high-concentration squaraine solution in ②, and mix thoroughly.

[0035] ④React at room temperature for a few minutes, and you can see the process of the mixed solution becoming clear and then crystals precipitate out immediately. The reaction can be completed in 5 minutes to obtain strip-shaped high-crystallinity UTSA-280.

[0036] ⑤ Filtrate the product and wash ...

Embodiment 2

[0038] Through the improvement of Example 2, the yield is increased by increasing the reactant concentration. Conditioning solvent and NH 3 ·H 2 O addition amount to synthesize UTSA-280 (improved synthesis 2):

[0039] ①Add 10.944g squarylium into 100mL distilled water, stir well to form a supersaturated squarylium solution.

[0040] ②Add 16mL NH 3 ·H 2 O (25%), add while stirring. At this point, most of the squaraine is soluble, forming a high-concentration squaraine solution.

[0041] ③Add 100mL of 22.656g calcium nitrate tetrahydrate solution to the high-concentration squaraine solution in ②, and mix thoroughly.

[0042] ④React at room temperature for a few minutes, and you can see the process of the mixed solution becoming clear and then crystals precipitate out immediately. The reaction can be completed in 5 minutes to obtain strip-shaped high-crystallinity UTSA-280.

[0043] ⑤ Filtrate the product and wash it three times with distilled water, and obtain the corre...

Embodiment 3

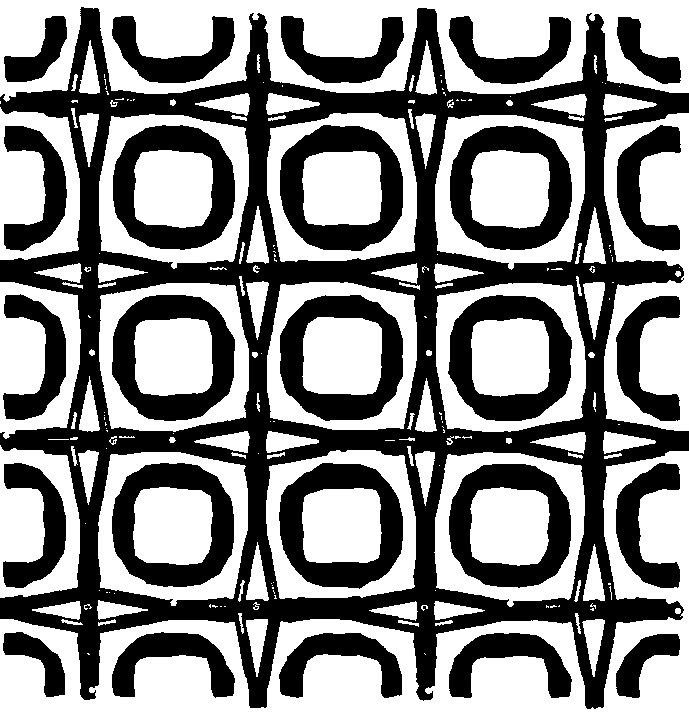

[0045] After the UTSA-280 with high crystallinity is obtained through a large-scale synthesis method, the molding technology of PMMA binder is used to form UTSA-280:

[0046] ① Put 1 g of the UTSA-280 crystal obtained in Example 2 into a small beaker.

[0047] ②Add 5%, 10% or 15% PMMA to 5mL of ethyl acetate solution, stir well to form PMMA ethyl acetate solution.

[0048] ③ Add the ethyl acetate solution of PMMA to the UTSA-280 crystal in ①, and mix thoroughly for half an hour.

[0049] ④ Draw up the mixture in ③ with a syringe, and then inject the mixture slowly.

[0050] ⑤ Wait for the injection to dry naturally, dissolve and remove to get the nearly spherical shaped UTSA-280. The thermal stability and water stability of the formed product are guaranteed, which is enough to meet the requirements of general adsorption environment.

[0051] Table 1 Molding process of UTSA-280 with different amounts of binder added

[0052]

[0053] Table 2 The stability of molding UTSA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com