A control method for efficiently separating vanadium-chromium wastewater by using modified chelating resin

A technology of chelating resin and control method, which is applied in water treatment parameter control, chemical instruments and methods, water pollutants, etc. It can solve the problems of inability to separate vanadium and chromium, co-precipitation of vanadium and chromium in wastewater, etc., and achieve the effect of vanadium separation High efficiency and improved adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

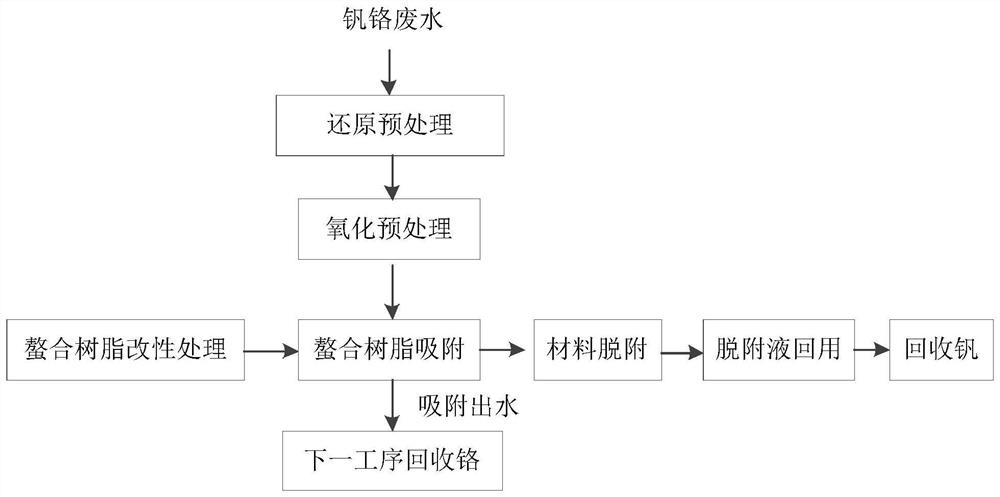

[0045] The process flow diagram of the control method for the efficient separation of vanadium-chromium waste water using modified chelating resin of the present embodiment is as follows: figure 1 shown, including the following steps:

[0046] Step 1) Vanadium-chromium waste water enters the reduction pretreatment device, adds sodium thiosulfate for reduction, the dosage of the sodium thiosulfate is 1% (mass volume ratio), and stirs for 30min to remove the high-valent vanadium and chromium in the waste water. Fully restored to a low price state;

[0047] The existing valence state of vanadium and chromium elements in raw water is relatively complex, and exists in a mixed form of high valence state and low valence state. The reduction is mainly to reduce chromium elements to the form of low valence state. 6+ easily reduced to Cr 3+ . In the reduction reaction, the following reactions mainly occur:

[0048] Cr 2 O 7 2- →Cr 3+ (reverted from +6 to +3);

[0049] CrO 4 2...

Embodiment 2

[0073] The control method for efficiently separating vanadium-chromium waste water by using modified chelating resin of the present embodiment comprises the following steps:

[0074] Step 1) Vanadium-chromium wastewater enters the reduction pretreatment device, is added with sodium bisulfite for reduction, the dosage of the reducing agent is 5% (mass volume ratio), and stirred for 120min to fully reduce the vanadium and chromium elements in the wastewater to a low-priced state ;

[0075] Step 2) take the reduced effluent of step 1), and adjust the pH value of the waste water to 4 with sodium hydroxide;

[0076] Step 3) take the effluent after the alkali adjustment in step 2) and add hydrogen peroxide for oxidation, and the oxidation-reduction potential of the waste water after oxidation is controlled at 600mv;

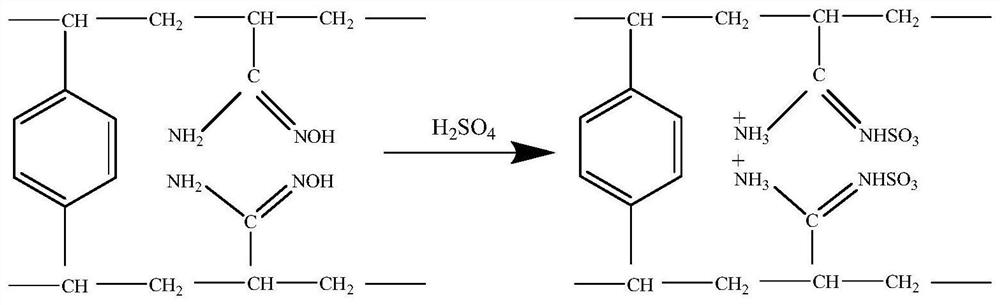

[0077] Step 4) Modification of the guanidine chelating resin, using 20% sulfuric acid acidity, the sulfuric acid pickling flow rate is controlled to 1BV / h, the pick...

Embodiment 3

[0087] The control method for efficiently separating vanadium-chromium waste water by using modified chelating resin of the present embodiment comprises the following steps:

[0088] Step 1) Vanadium-chromium wastewater directly enters the reduction pretreatment device, adds sodium metabisulfite for reduction, the dosage of the reducing agent is 2% (mass volume ratio), and stirs for 60min to fully reduce the vanadium-chromium in the wastewater to a low-priced state;

[0089] Step 2) take the reduced effluent of step 1), and adjust the pH of the waste water to 3.5 with sodium hydroxide;

[0090] Step 3) take the effluent after the alkali adjustment in step 2) by ozone oxidation, and control the oxidation-reduction potential of the oxidized wastewater at 500mv by controlling the oxidation reaction time;

[0091] Step 4) pickling the pyridine-type chelating resin with 10% hydrochloric acid, the hydrochloric acid pickling flow rate is controlled to be 2BV / h, the pickling time is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com