Modified light-cured polyester acrylic resin and synthesis method thereof

A polyester acrylic, synthetic method technology, applied in ink, household appliances, applications, etc., can solve the problems of poor ink wettability and dispersibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The invention provides a modified photocurable polyester acrylic resin, the modified photocurable polyester acrylic resin comprises the following components in parts by mass: 100 parts of trimethylolpropane, 60 parts of benzoic acid, 50 parts of phthalic anhydride, 15 Parts of xylene, 150 parts of trimethylolpropane triacrylate, 15 parts of epoxidized soybean oil, 50 parts of rosin, 30 parts of acrylic acid, 1.5 parts of p-toluenesulfonic acid, 1.5 parts of triphenylphosphine, 0.3 parts of p-phenylene Diphenol and 0.2 parts of BHT.

[0023] The above-mentioned modified photocurable polyester acrylic resin improves the wetting and dispersibility of the resin to organic pigments by introducing rosin with a honeycomb structure and adding epoxy soybean oil, so that the gloss and transfer performance of the ink are significantly improved, and, due to The molecular weight of rosin and epoxidized soybean oil is relatively large. The introduction of such high molecular weight s...

Embodiment 2

[0046] The invention provides a modified photocurable polyester acrylic resin, which comprises the following components in parts by mass: 110 parts of trimethylolpropane, 65 parts of benzoic acid, 55 parts of phthalic anhydride, 17 Parts of xylene, 175 parts of trimethylolpropane triacrylate, 20 parts of epoxidized soybean oil, 55 parts of rosin, 35 parts of acrylic acid, 2.2 parts of p-toluenesulfonic acid, 2.2 parts of triphenylphosphine, 2.4 parts of p-phenylene Diphenols and 0.25 parts of BHT.

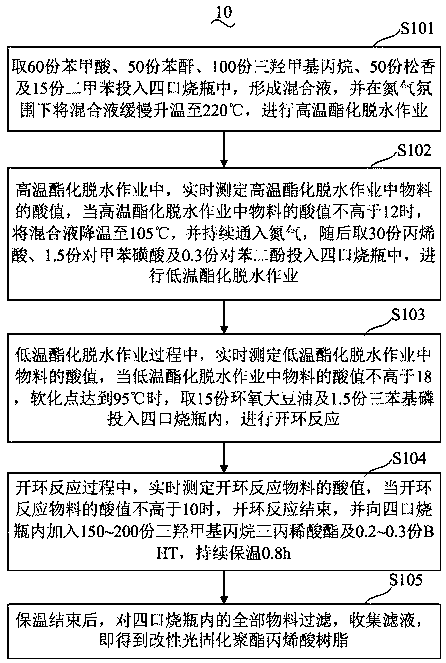

[0047] see figure 2 , the present invention also provides a synthetic method 20 of a modified photocurable polyester acrylic resin, the synthetic method 20 of the modified photocurable polyester acrylic resin comprises the following steps:

[0048] S201: Put 65 parts of benzoic acid, 55 parts of phthalic anhydride, 110 parts of trimethylolpropane, 55 parts of rosin and 17 parts of xylene into a four-necked flask to form a mixed solution, and slowly raise the temperature of the mi...

Embodiment 3

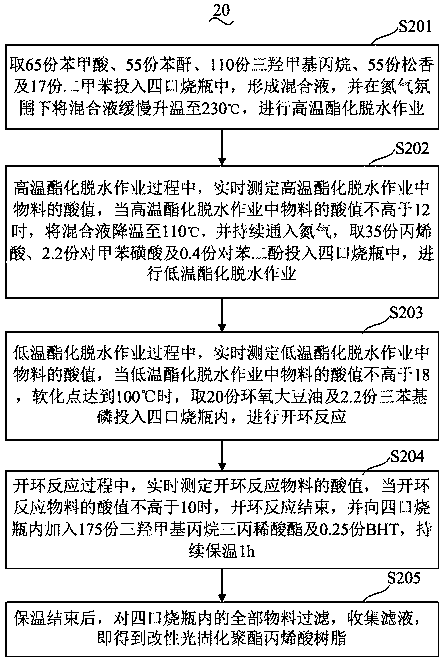

[0060] see image 3 , the invention provides a modified photocurable polyester acrylic resin, the modified photocurable polyester acrylic resin comprises the following components in parts by mass: 120 parts of trimethylolpropane, 70 parts of benzoic acid, 60 parts of phthalic anhydride, 20 parts of xylene, 200 parts of trimethylolpropane triacrylate, 25 parts of epoxidized soybean oil, 60 parts of rosin, 40 parts of acrylic acid, 3 parts of p-toluenesulfonic acid, 3 parts of triphenylphosphine, 0.5 parts of p- Hydroquinone and 0.3 parts of BHT.

[0061] The present invention also provides a synthetic method 30 of a modified photocurable polyester acrylic resin, the synthetic method 30 of the modified photocurable polyester acrylic resin comprises the following steps:

[0062] S301: Put 70 parts of benzoic acid, 60 parts of phthalic anhydride, 120 parts of trimethylolpropane, 60 parts of rosin and 20 parts of xylene into a four-necked flask to form a mixed solution, and slowly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap