High-strength polyvinyl alcohol gel and preparation method and application thereof

A polyvinyl alcohol gel, polyvinyl alcohol technology, applied in the fields of materials and biomaterials, can solve the problems of insufficient effectiveness, safety and quality controllability, the gel cannot meet cartilage implantation, excessive boron release and other problems, Achieve the effect of ensuring biological safety, strengthening mechanical properties, and strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation of embodiment 1 polyvinyl alcohol gel

[0060] The polyvinyl alcohol (PVA) used in this example was purchased from Aladdin Company, with a weight average molecular weight of 120 kDa, a molecular weight distribution of 1.5, and an alcoholysis degree of 99.4%.

[0061] 1 # polyvinyl alcohol gel

[0062] 1) Preparation of PVA aqueous solution: weigh 25g of PVA into a 250mL three-neck flask, add 100mL of purified water, place the flask in a water bath at 95°C, heat and stir until the PVA is completely dissolved, and obtain the PVA aqueous solution. use;

[0063] 2) Chemical crosslinking: Weigh 15g of PVA aqueous solution in a 100mL beaker, add 1.5mL of NaOH solution (15.0wt.%) to the above PVA aqueous solution, stir evenly, then add 60mg of BDDE, continue stirring evenly, Fill into the mold, seal and place the PVA sample in a water bath at 25°C for chemical crosslinking for 24 hours;

[0064] 3) Physical cross-linking: after chemical cross-linking in a...

experiment example 1

[0090] The unconfined compressive modulus of experimental example 1 polyvinyl alcohol gel

[0091] With the 1 prepared in the embodiment of the present invention 1 # polyvinyl alcohol gel, 2 # The C1 prepared in polyvinyl alcohol gel, comparative example # Polyvinyl alcohol gel and C2 # Polyvinyl alcohol gel is typical, and the unconfined compression modulus is tested by UTM6202 electronic universal tensile machine equipment. details as follows:

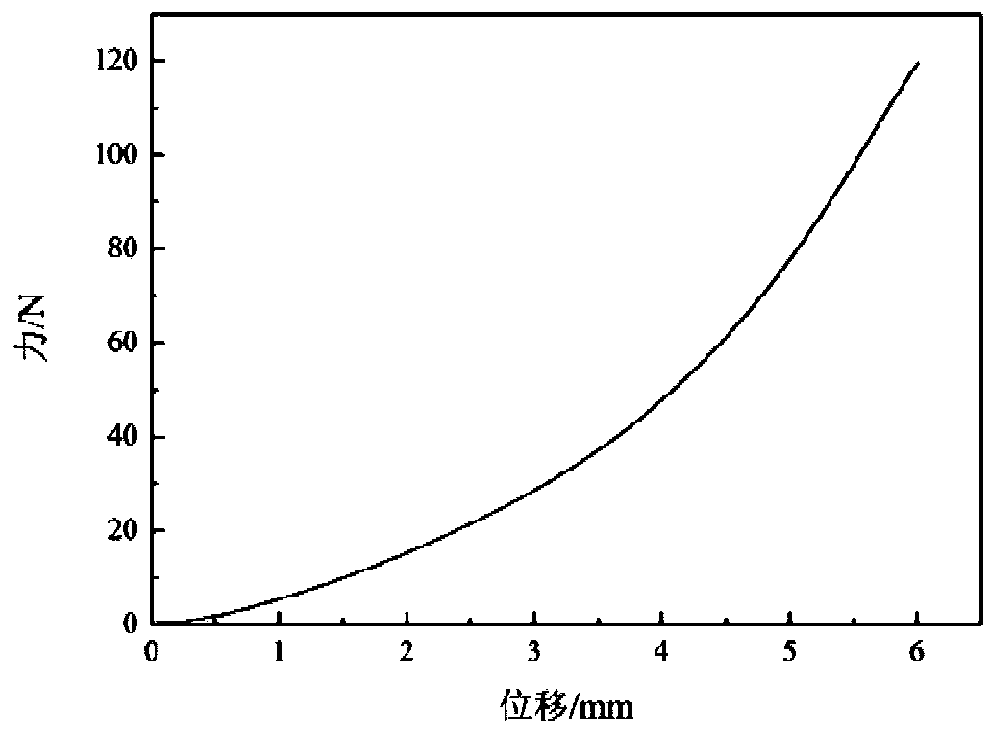

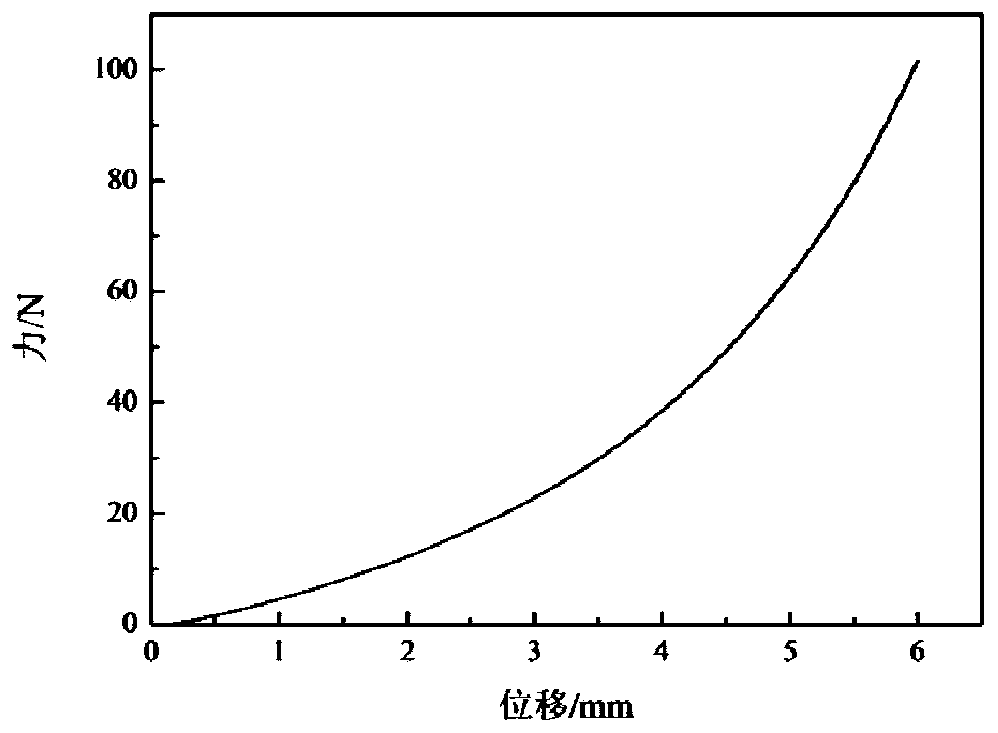

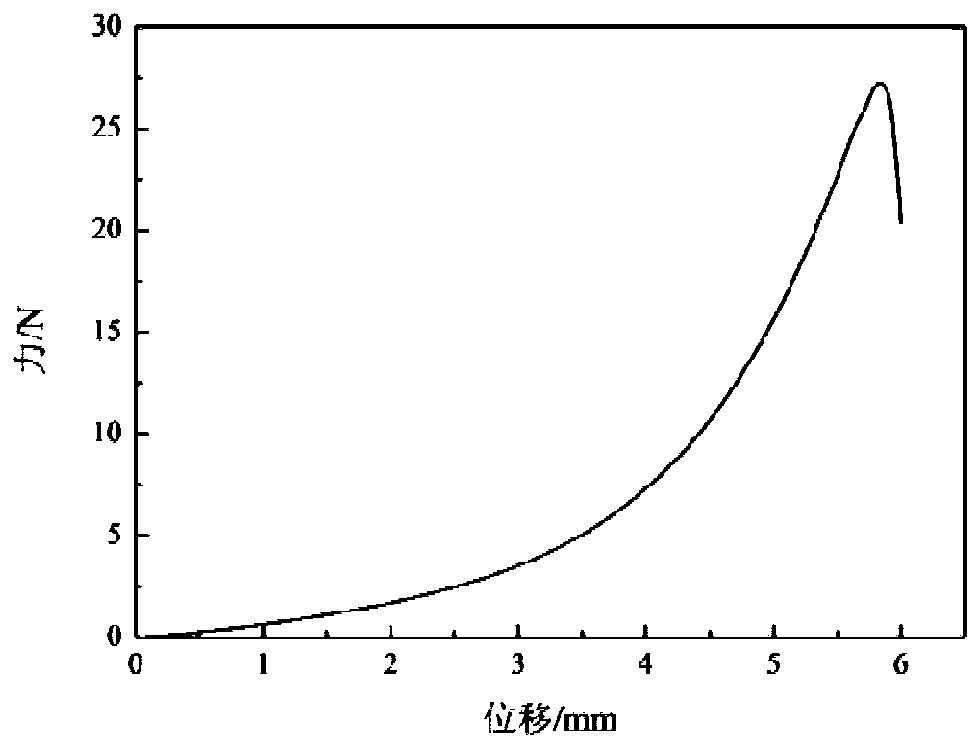

[0092] The above samples were made into a cylindrical polyvinyl alcohol gel with a diameter of 0.85 cm and a height of 1 cm, and the unconfined compression modulus was tested; testing conditions: compression speed 50 mm / min, maximum deformation 60%. 1 prepared in Example 1 # polyvinyl alcohol gel, 2# The C1 prepared in polyvinyl alcohol gel, comparative example # Polyvinyl alcohol gel and C2 # The relationship between stress and compression displacement of polyvinyl alcohol gel is as follows: figure 1 , figure 2 , image 3...

experiment example 2

[0098] Experimental Example 2 Unconfined Cyclic Compression of Polyvinyl Alcohol Gel

[0099] With the 1 prepared in the embodiment of the present invention 1 # The C3 prepared in polyvinyl alcohol gel, comparative example 2 # Polyvinyl alcohol gel is typical, and the UTM6202 electronic universal tensile machine equipment is used to detect unconfined cycle compression. details as follows:

[0100] The above sample was made into a cylindrical polyvinyl alcohol gel with a diameter of 0.85 cm and a height of 1 cm, and the unconfined compression modulus was tested; test conditions: compression speed 50 mm / min, maximum deformation amount 60%, cyclic compression 10 times, and observed coagulation Whether the glue will crumble. 1 prepared in Example 1 # The C3 prepared in polyvinyl alcohol gel, comparative example 1 # The unconfined cycle compression test results of both polyvinyl alcohol gels are listed in Table 2.

[0101] Table 2 Unconfined cyclic compression test results of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com