Production mold for porous reticular cultured meat, production method of porous reticular muscle tissue based on mold and application of production method

A technology of muscle tissue and production method, applied in the field of stem cells and animal cell cultured meat, to achieve the effect of enhancing diffusion, promoting differentiation process, and facilitating excretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

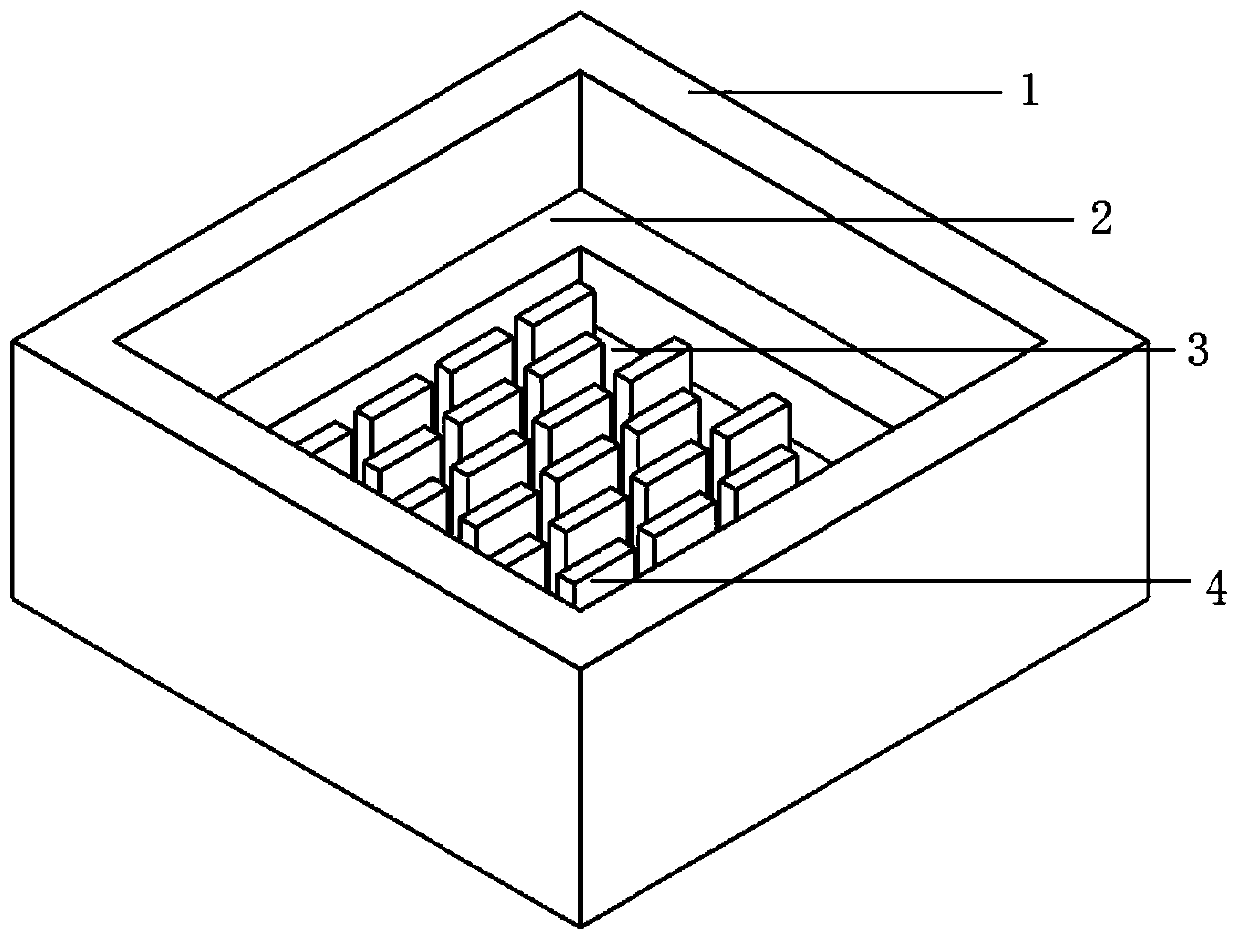

[0051] Embodiment 1 manufactures the positive mold of cultured meat production mould:

[0052] 1) Utilize three-dimensional drawing software to construct the three-dimensional CAD model of the positive mold with regularly arranged columnar grooves, and carry out data processing to the model based on the refined STL model method; design the positive mold for manufacturing the cultured meat production mold of the present invention, the positive mold The longitudinal section of the mold is a three-step structure, the first step from bottom to top is used to form the outer wall 1 of the mold of the present invention, the second step is used to form the first groove 2 of the mold of the present invention, and the third step is used to form the second groove 3 and the micro-column 4 . The height of the second step of the positive mold is 3-7mm, and the height of the third step is 2-6mm. The third step is provided with several columnar grooves (for micro-column 4 production). The ar...

Embodiment 2

[0055] Embodiment 2 Utilizes male mold to make cultured meat production mold

[0056] Weigh liquid A and liquid B of Dow Corning Sylgard 184 silicone rubber PDMS, and mix them at a mass ratio of 10:1. Carefully pour the well-mixed PDMS (polydimethylsiloxane) into the positive mold. Put the PDMS and male mold in a vacuum degasser, and the degassing time is 1-16h. At the same time, place the PDMS and the positive mold at 25°C for 24 hours to solidify. Then use a scalpel to cut the contact part between PDMS and the male mold, and use the other end of the weighing spoon to move the PDMS and the male mold around the mold. By squeezing the PDMS and the male mold, the cultured meat can be produced into the mold and its regularity. The arrayed micro-columns are taken out relatively completely, the number of broken columns when taken out is 0%-20%, and the remaining number of micro-columns is more than 90% to be used for the production of subsequent cultured meat. The mold taken out...

Embodiment 3

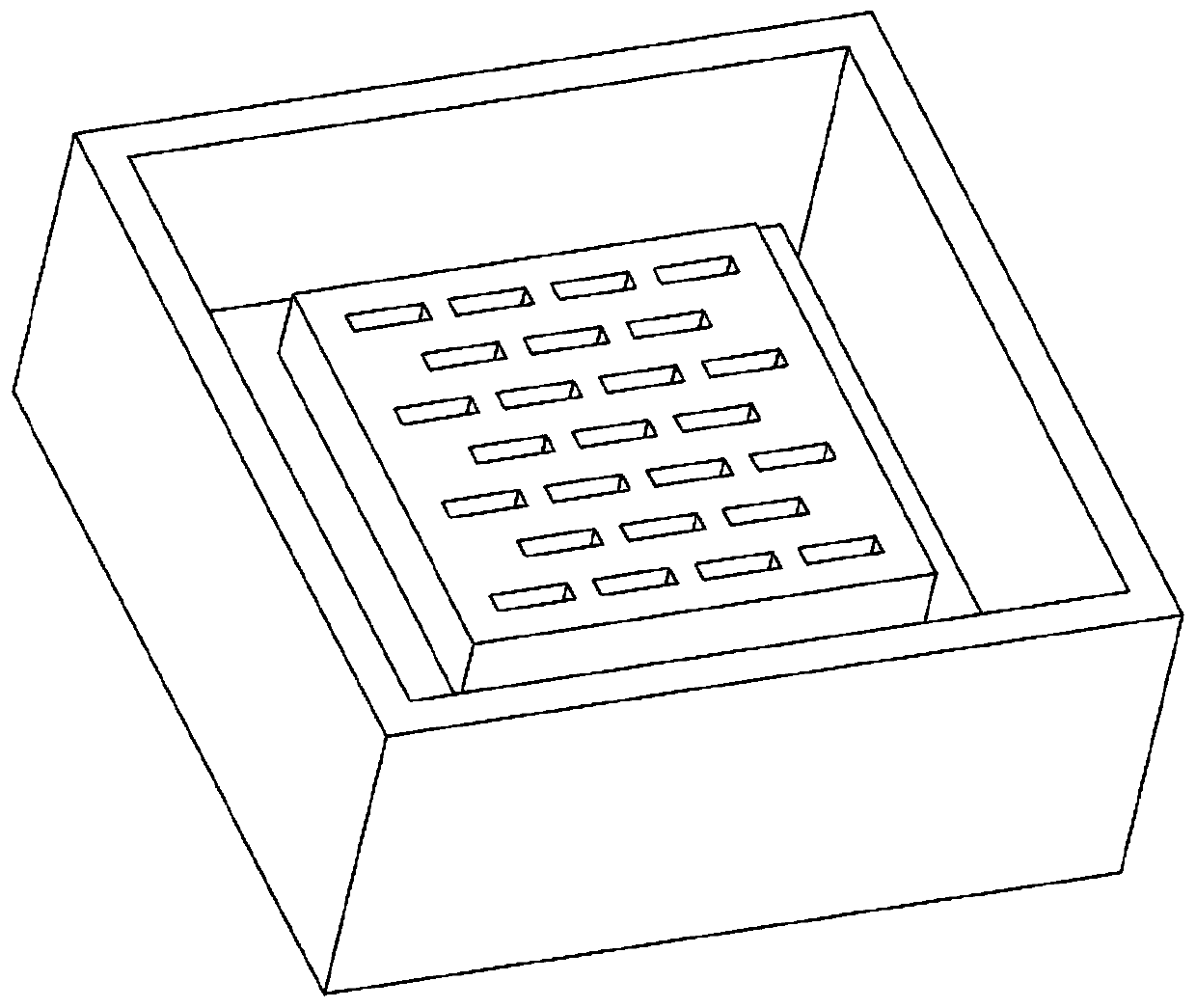

[0059] A porous mesh cultured meat production mold, the mold is a cuboid with an open upper end, including an outer wall 1, a first groove 2, a second groove 3, and a micro column 4;

[0060] The longitudinal section of the outer wall 1 is in the shape of two steps downwards, the first level from top to bottom is the bottom of the first groove 2 , and the second level is the bottom of the second groove 3 .

[0061] The length of the outer wall 1 is 25 mm; the width is 25 mm; the height is 12 mm, forming a cuboid with an open upper end.

[0062] The first groove 2 is centrally arranged on the inner side of the outer wall 1, and the length of the first groove 2 is 20mm; the width is 20mm; and the height is 5mm. The width of the base of the first groove 2 is 2 mm.

[0063] The second groove 3 is centrally arranged at the bottom of the first groove 2; the length of the second groove 3 is 16 mm; the width is 16 mm; the height is 3 mm, and the thickness of the bottom of the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com