Association polymer and preparation method thereof, and applications in high-temperature-resistant fracturing fluids

A technology of hydrophobic association and synthesis method, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of high cost, limited application, large amount of viscoelastic surfactant, etc., and achieve excellent viscoelasticity, high Temperature resistance, small dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 0.5mol β-cyclodextrin and 0.5mol maleic anhydride in N,N-dimethylformamide and react at 80°C for 10 hours to obtain monomer MAH-β-CD;

[0032] (2) In an ice bath, add 0.1mol N,N-didodecylamine and 6N sodium hydroxide (50ml) into dichloromethane and pass through dry nitrogen, and use a constant pressure funnel to dissolve methacryloyl chloride (0.104mol) Slowly added to the mixed solution of dichloromethane, stirred for 2 hours, separated, the organic phase was washed with distilled water until neutral, dried and rotary evaporated to obtain the monomer DiC 12 AM;

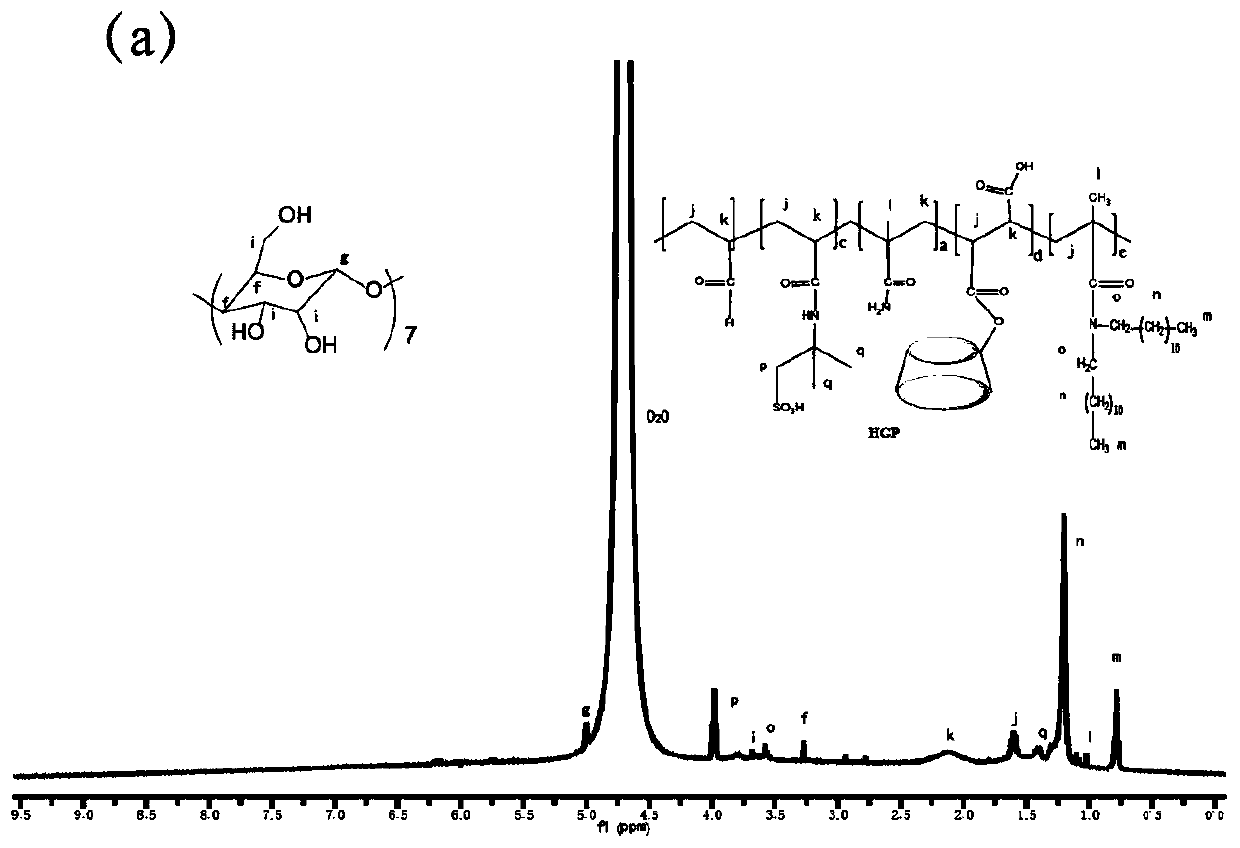

[0033] (3) The mole fraction is 5% MAH-β-CD and the mole fraction is 6% DiC 12 Add AM and 70% acrylamide by mole fraction, 8% acrylic acid and 10% 2-acrylamido-2-methylpropanesulfonic acid by mole fraction to deionized water to form an aqueous solution with a monomer concentration of 20%, and pass nitrogen gas After half an hour, the temperature was raised to 45°C and an initiator was added, the...

Embodiment 2

[0036] Add a mole fraction of 0.1% MAH-β-CD and a mole fraction of 0.1% DiC 12 AM (synthesized in Example 1) and mole fraction is 99.5% acrylamide, and 0.15% acrylic acid and mole fraction are that 0.2% 2-acrylamido-2-methylpropanesulfonic acid joins deionized water and is made into monomer concentration 15% aqueous solution, nitrogen gas for half an hour, the temperature was raised to 45°C and an initiator was added, and the hydrophobic polymer was obtained after polymerization for 6 hours.

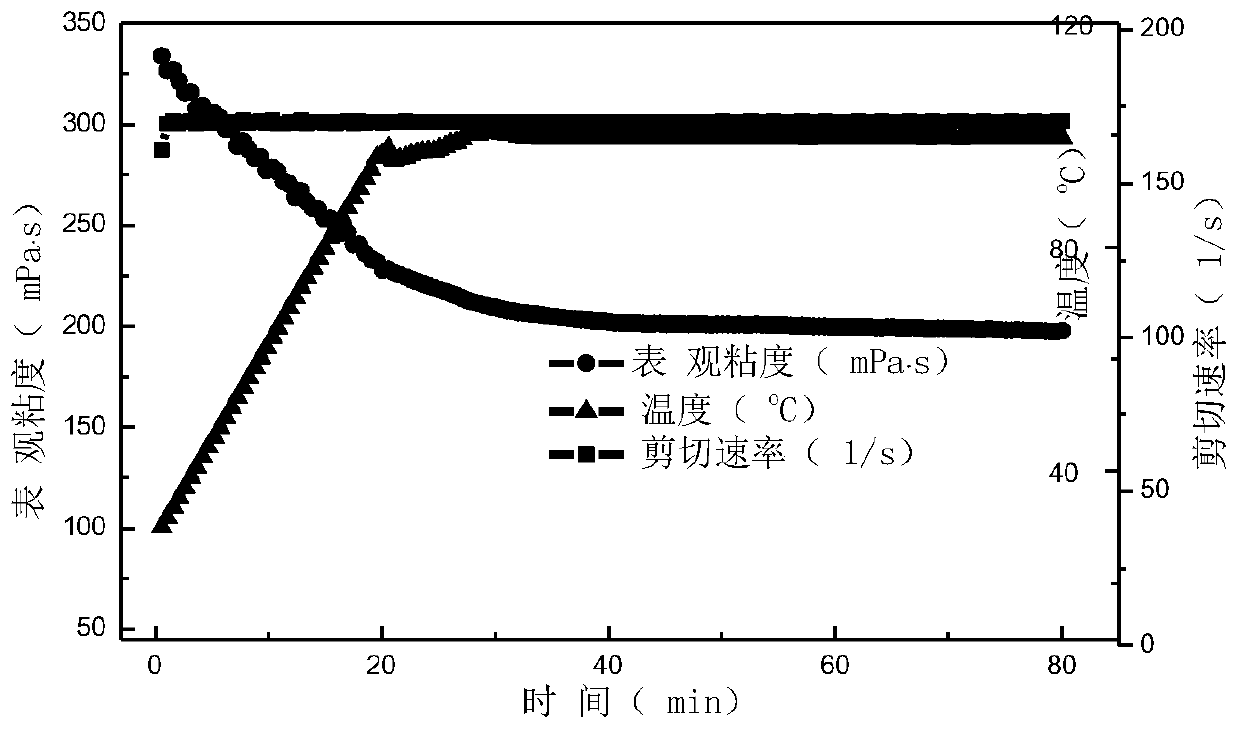

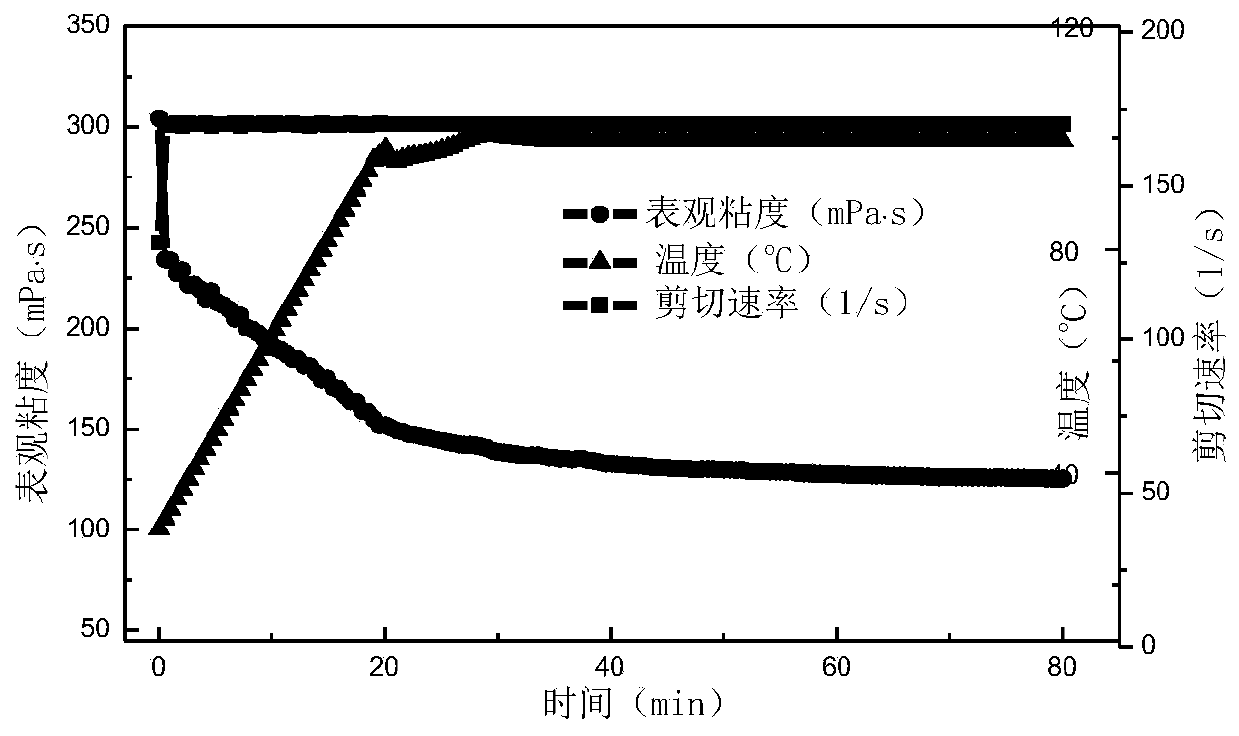

[0037] The fracturing fluids prepared with 0.6% hydrophobic association polymer and 0.4% hydrophobic association polymer were treated at 100℃ and 170s respectively -1 rheology such as Figure 4 and Figure 5 shown. After shearing for 2 hours, the viscosities remained above 150 mPa·s and 100 mPa·s respectively, which can meet the requirements of on-site construction; the static suspended sand test showed that there was no obvious settlement for 2 hours, and the viscosity of the gel bre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com