Preparation of starch-based waterborne polyurethane emulsion and application of starch-based waterborne polyurethane emulsion in packaging paper

A water-based polyurethane and emulsion technology, used in packaging paper, wrapping paper, packaging, etc., can solve the problems of difficult hydration of PU prepolymer, difficulty in obtaining water dispersion, and large particle size of WPU, and achieve film-forming properties. And the effects of improved biodegradability, improved surface water resistance, and fast curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

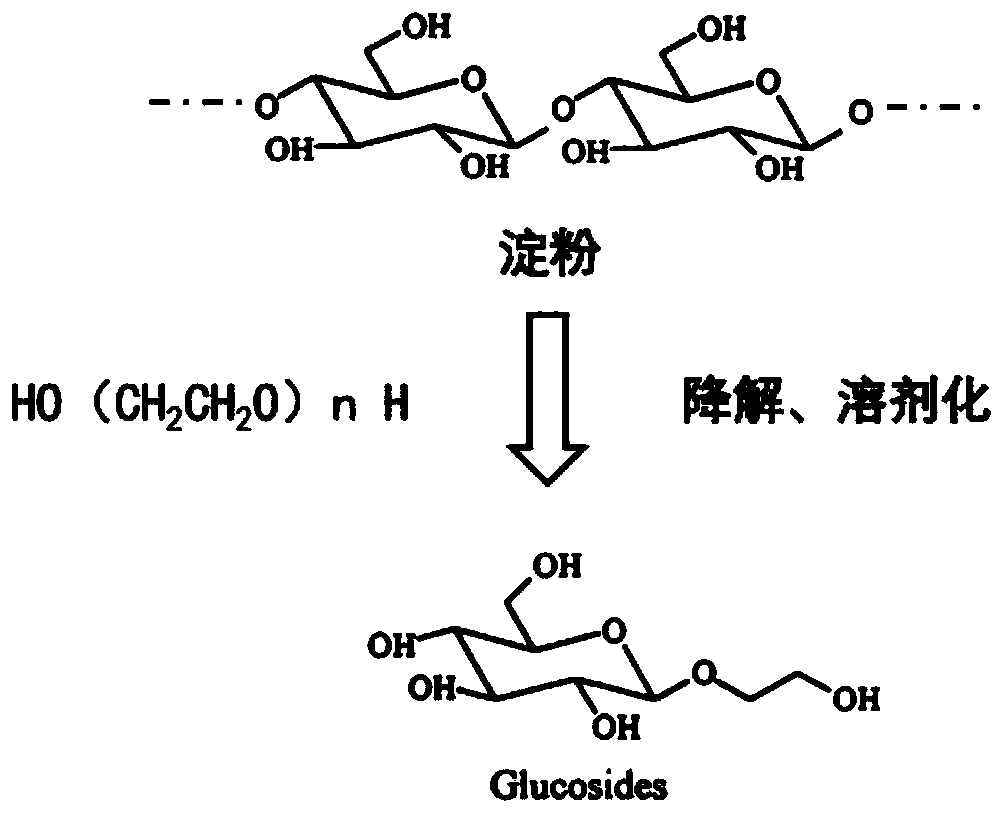

[0040] The preparation of embodiment 1 liquefied cornstarch-based aqueous polyurethane emulsion

[0041] (1) Take 56g of waxy polyethylene glycol 2000 and put it in a three-necked flask, and fully melt it at 130°C; take 20g of fully dried cornstarch and add it to polyethylene glycol in three times, and add it while stirring to avoid starch hanging on the wall , until the starch and polyethylene glycol are completely mixed and there are no starch lumps;

[0042] (2) Add 0.82g of 98% concentrated sulfuric acid dropwise in the flask, stir and insulate for 40min, add NaOH to neutralize the material, cool and discharge, the product is a wine red viscous fluid starch polyol liquefaction product, and its hydroxyl value is 265mgKOH / g , the apparent viscosity is 1860mPa.s;

[0043] (3) Put a 500ml four-neck flask in an oil bath, equip with a cantilever electric stirrer, a reflux condenser, and feed nitrogen. Take 54.02 g of the above-mentioned corn starch liquefaction product and put...

Embodiment 2

[0045] The preparation of embodiment 2 liquefied tapioca starch-based waterborne polyurethane

[0046] (1) Take 50g of waxy polyethylene glycol 4000 and put it in a three-necked flask, and fully melt it at 140°C; take 10g of fully dried tapioca starch and add it to the polyethylene glycol, and add it while stirring to avoid starch hanging on the wall until Starch and polyethylene glycol are completely mixed without starch lumps;

[0047] (2) Add 0.5 g of 98% concentrated sulfuric acid dropwise in the flask, add NaOH to neutralize the material after stirring and insulated for 30 min, and cool and discharge. The product is a wine red viscous fluid starch polyol liquefaction product, and its hydroxyl value is 230 mgKOH / g , the apparent viscosity is 1200mPa.s;

[0048] (3) Put a 500ml four-neck flask in an oil bath, equip with a cantilever electric stirrer, a reflux condenser, and feed nitrogen. Take 50.10 g of the above-mentioned tapioca starch liquefaction product and place it...

Embodiment 3

[0050] The preparation of embodiment 3 potato starch-based aqueous polyurethane emulsions

[0051] (1) Take 40g of waxy polyethylene glycol 2000 and place it in a three-necked flask, and fully melt it at 120°C; take 30g of fully dried potato starch and add it to the polyethylene glycol, and add it while stirring to avoid starch hanging on the wall until Starch and polyethylene glycol are completely mixed without starch lumps;

[0052] (2) Add 1.5 g of 98% concentrated sulfuric acid dropwise in the flask, add NaOH to neutralize the material after stirring and insulated for 15 min, and cool and discharge the product. The product is a yellow-brown viscous fluid-like starch polyol liquefaction product, and its hydroxyl value is 406 mgKOH / g , the apparent viscosity is 3200mPa.s;

[0053] (3) Put a 500ml four-neck flask in an oil bath, equip with a cantilever electric stirrer, a reflux condenser, and feed nitrogen. Take 50.16g of the above-mentioned potato starch liquefaction prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com