Industrial waterborne acrylic polyurethane anticorrosive coating with heavy-duty anticorrosion and long-time weather resistance, and preparation method thereof

An acrylic polyurethane, anti-corrosion coating technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of long-term water resistance not meeting the requirements, poor long-term weather resistance, poor long-term chemical resistance, etc., to achieve excellent The effect of long-term weather resistance, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

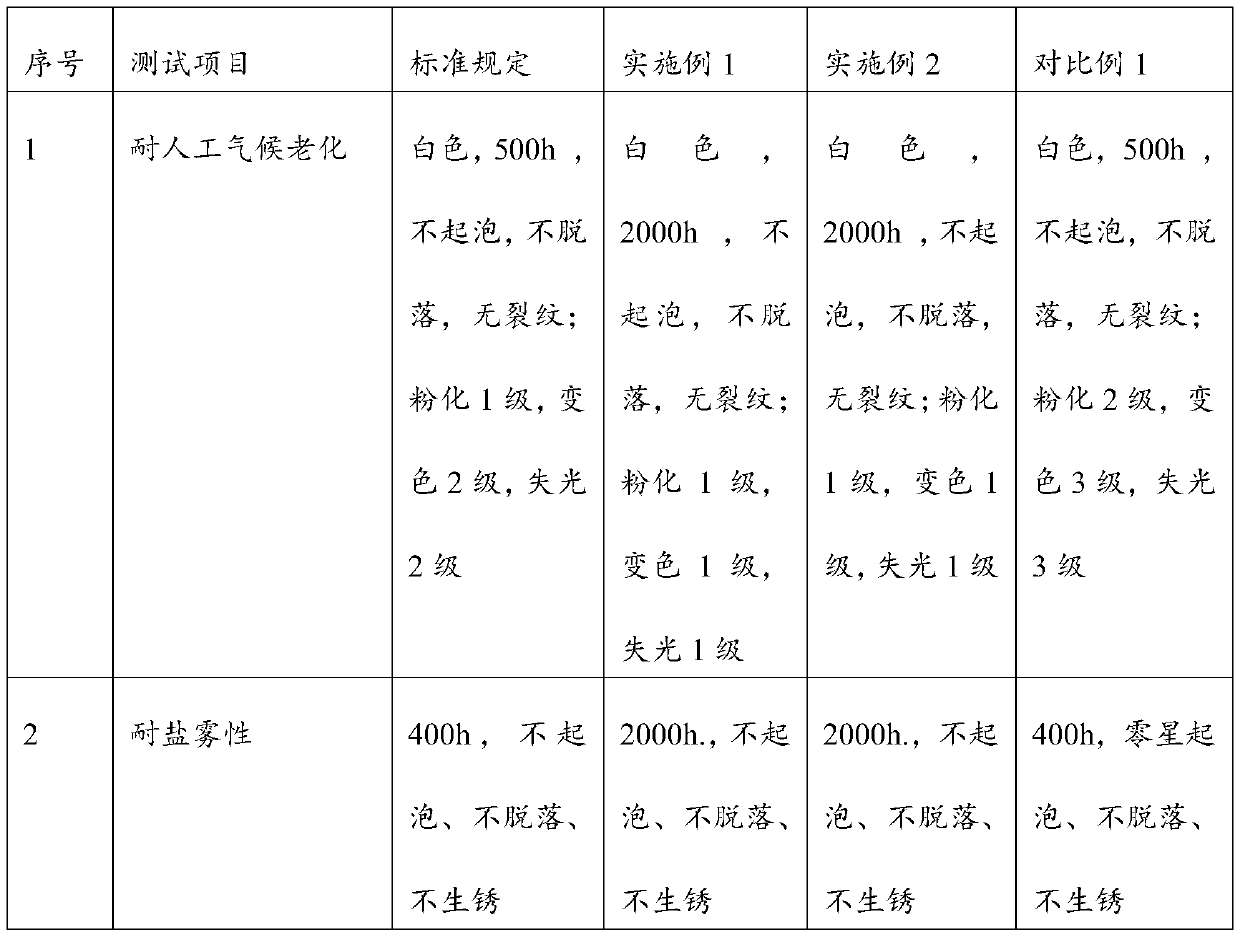

Examples

Embodiment 1

[0041] This embodiment provides an industrial heavy-duty anti-corrosion long-term weather-resistant water-based acrylic polyurethane anti-corrosion coating and a manufacturing method thereof.

[0042] The steps of the manufacturing method include: mixing 0.2 parts by weight of deionized water with 0.01 parts by weight of high-efficiency high molecular weight block copolymer solution dispersant, 0.01 parts by weight of polysiloxane and polyethylene glycol hydrophobic mixture BYK in a stainless steel bucket -093 defoamer, disperse at high speed for 5 minutes; then add 0.01 parts by weight of Tinuvin 1130 benzotriazole UV absorber, 0.02 parts by weight of TINUVIN 292 light hindered amine stabilizer, 0.3 parts by weight of rutile titanium dioxide CR828, 0.3 parts by weight 1 part of wet-process sericite powder, high-speed dispersion 20mim; then grind the slurry until the fineness is less than or equal to 50μm; then stir the slurry evenly, add 0.02 parts by weight of polyether silox...

Embodiment 2

[0046] This embodiment provides an industrial heavy-duty anti-corrosion long-term weather-resistant water-based acrylic polyurethane anti-corrosion coating and a manufacturing method thereof.

[0047] The steps of the manufacturing method include: mixing 0.3 parts by weight of deionized water with 0.02 parts by weight of high-efficiency high molecular weight block copolymer solution dispersant, 0.01 parts by weight of polysiloxane and polyethylene glycol hydrophobic mixture BYK in a stainless steel bucket -093 defoamer, disperse at high speed for 5 minutes; then add 0.03 parts by weight of Tinuvin 1130 benzotriazole ultraviolet absorber, 0.03 parts by weight of TINUVIN 292 light hindered amine stabilizer, 0.3 parts by weight of rutile titanium dioxide CR828, 0.3 parts by weight 1 part of wet-process sericite powder, high-speed dispersion 20mim; then grind the slurry until the fineness is less than or equal to 50μm; then stir the slurry evenly, add 0.02 parts by weight of polyet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap