Microorganism fermenting tank for producing liquid feed additive

A technology for microbial fermentation and liquid feed, which is applied in the field of microbial fermentation tanks for the production of liquid feed additives, can solve the problems of limited application and promotion of microbial strains, low fermentation efficiency, poor ventilation, etc., and achieves broad market prospects and application prospects. Good effect, precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

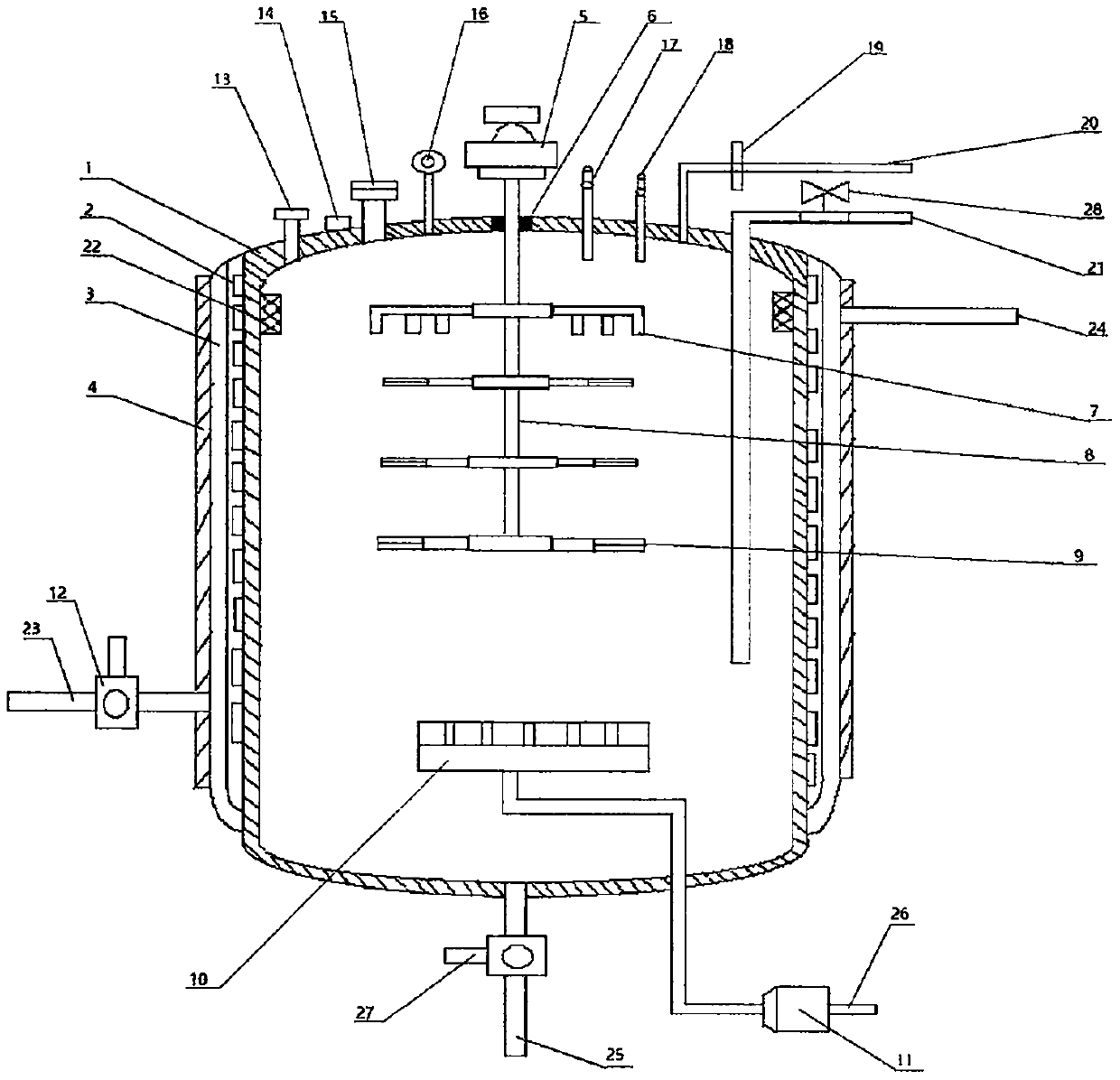

[0010] see figure 1 , through the description of the embodiments, the specific implementation of the present invention, such as the relationship between the various parts involved, the role and working principle of each part, and the method of operation and use, etc., will be further described in detail to help engineering in this field. The technical personnel have a more complete, accurate and in-depth understanding of the concept of the present invention and the technical solution.

[0011] The microbial fermenter for liquid feed additive production of the present invention has a structure comprising a fermenter body 1, a heating pipe 2, a steel cylinder cover 3, an outer insulation layer 4, a motor 5, a sterile shaft seal 6, a defoamer 7, a stirring shaft 8, Stirrer 9, air injection device 10, air filter 11, water valve 12, sight glass 13, digital display thermometer 14, feed inlet 15, pressure gauge 16, PH meter 17, dissolved oxygen detector 18, automatic control valve 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com