Method for preparing Janus foamy copper with asymmetric wettability and efficient mist collection ability

A foamed copper and wettability technology is applied in the field of Janus material preparation, which can solve the problems of low practicability, complicated preparation steps of Janus materials, and fluorine-containing preparation materials, and achieves the effects of low cost, good high temperature resistance, and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

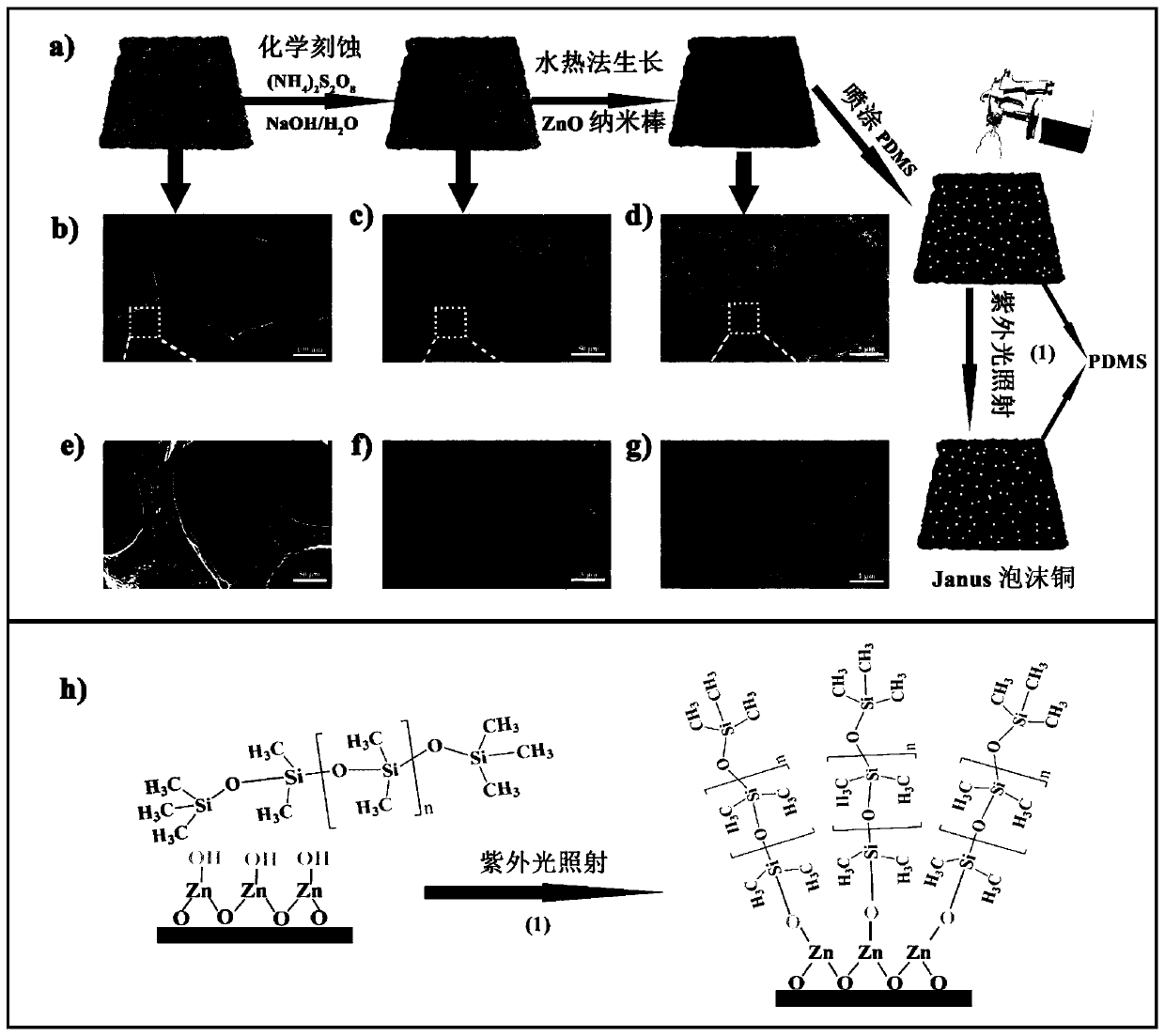

[0027] 1. Prepare copper hydroxide nanowires on copper foam: cut the copper foam into 3*3cm 2 slices. First, in order to remove the pollutants on the copper foam surface, ultrasonic cleaning was performed with acetone, ethanol, and deionized water for 5 min, and then the oxide layer was removed with 0.1M hydrochloric acid solution. The treated foamed copper was etched in a mixed aqueous solution of 1M sodium hydroxide and 0.05M ammonium persulfate for 40 minutes, washed with deionized water and dried in a vacuum oven for 40 minutes to obtain a surface covered with copper hydroxide nanowires.

[0028]2. Grow ZnO nanorods on copper hydroxide nanowires: Soak the etched copper foam in 0.15M zinc acetate solution for 15s, take it out and dry it for 5min, rinse with ethanol, repeat the above steps 5 times and put it in 300℃ Inject seeds in a high temperature muffle furnace. After seed injection, the foamed copper is immersed in a mixed aqueous solution of 0.025M zinc nitrate and 0...

Embodiment 2

[0032] 1. Prepare copper hydroxide nanowires on copper foam: cut the copper foam into 3*3cm 2 slices. First, in order to remove the pollutants on the copper foam surface, ultrasonic cleaning was performed with acetone, ethanol, and deionized water for 5 min, and then the oxide layer was removed with 0.1M hydrochloric acid solution. The treated foamed copper was etched in a mixed aqueous solution of 1M sodium hydroxide and 0.05M ammonium persulfate for 40 minutes, washed with deionized water and dried in a vacuum oven for 40 minutes to obtain a surface covered with copper hydroxide nanowires.

[0033] 2. Grow ZnO nanorods on copper hydroxide nanowires: Soak the etched copper foam in 0.15M zinc acetate solution for 15s, take it out and dry it for 5min, rinse with ethanol, repeat the above steps 5 times and put it in 300℃ Inject seeds in a high temperature muffle furnace. After seed injection, the foamed copper is immersed in a mixed aqueous solution of 0.025M zinc nitrate and ...

Embodiment 3

[0037] 1. Prepare copper hydroxide nanowires on copper foam: cut the copper foam into 3*3cm 2 slices. First, in order to remove the pollutants on the copper foam surface, ultrasonic cleaning was performed with acetone, ethanol, and deionized water for 5 min, and then the oxide layer was removed with 0.1M hydrochloric acid solution. The treated foamed copper was etched in a mixed aqueous solution of 1M sodium hydroxide and 0.05M ammonium persulfate for 40 minutes, washed with deionized water and dried in a vacuum oven for 40 minutes to obtain a surface covered with copper hydroxide nanowires.

[0038] 2. Grow ZnO nanorods on copper hydroxide nanowires: Soak the etched copper foam in 0.15M zinc acetate solution for 15s, take it out and dry it for 5min, rinse with ethanol, repeat the above steps 5 times and put it in 300℃ Inject seeds in a high temperature muffle furnace. After seed injection, the foamed copper is immersed in a mixed aqueous solution of 0.025M zinc nitrate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com