A high-efficiency low-concentration gas power generation system and its control method

A low-concentration gas and power generation system technology, applied in the field of high-efficiency and low-concentration gas power generation systems and their control, and power generation systems, can solve problems such as explosions, and achieve the effects of no noise, elimination of hidden dangers of explosion, and high energy conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

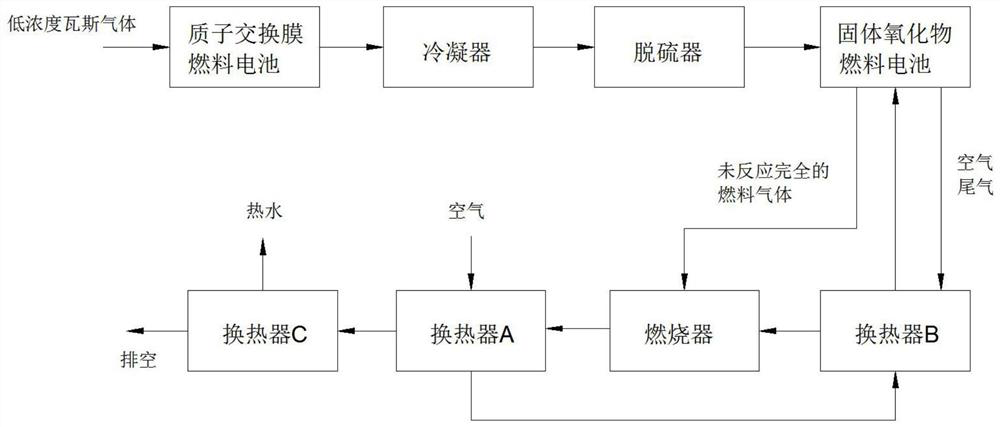

[0030] Embodiment 1: In this embodiment, the concentration of methane in low-concentration gas is about 5%;

[0031] After the low-concentration gas passes through the air electrode of the proton exchange membrane fuel cell, set the output current of the proton exchange membrane fuel cell, control the specific amount of oxygen consumption, and make the utilization rate of oxygen reach about 75%, and the main component of the gas coming out is 4.35 %CH 4 , 65.3% N 2 , 4.35% 0 2 , 26% water vapor, and a small amount of H 2 S, and then condense and remove part of the water vapor in the gas through the condenser, so that the content ratio of water vapor and methane in the mixed gas is about 2.5, so as to realize the reforming of methane, set the condensation temperature of the condenser to 51°C, and condense The composition of the final gas is as follows: 5.13% CH 4 , 76.94% N 2 , 5.13% 0 2 , 12.8% water vapor, and a small amount of H 2 S, the volume content ratio of oxygen...

Embodiment 2

[0038] Embodiment 2: In this embodiment, the methane concentration in the low-concentration gas is about 10%.

[0039] After the low-concentration gas passes through the air electrode of the proton exchange membrane fuel cell, set the output current of the proton exchange membrane fuel cell, control the specific amount of oxygen consumption, and make the utilization rate of oxygen reach about 53%, and the main component of the gas coming out is 9.1 %CH 4 , 64.6%N 2 , 8.1% 0 2 , 18.2% water vapor, and a small amount of H 2 S. At this time, the content ratio of water vapor and methane in the mixed gas is 2, and there is no need to remove water. The temperature of the condenser is set at 58°C, so that the content of water vapor in the mixed gas remains unchanged. At the same time, because the mixed gas also contains part of oxygen, Therefore, there is no need to add water vapor, and it can be directly used as reformed gas. The volume content ratio of oxygen and methane in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com