Preparation method and application of dendritic morphology FeNi3 phase electrocatalyst powder

A catalyst and morphology technology, applied in the field of preparation of FeNi3 phase electrocatalyst powder with dendritic morphology, can solve the problems of high cost, limited large-scale application, limited resources, etc., and achieve easy operation, excellent catalytic performance, beautiful dendrites and other problems. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Prepare a mixed aqueous solution of 0.04 mol / L nickel sulfate, 0.01 mol / L ferrous sulfate and 0.1 mol / L sodium sulfate as an electrodeposition solution; wash the copper foil with absolute ethanol and deionized water as an electrodeposition carrier. Using copper foil as the working electrode, Ag / AgCl electrode as the counter electrode, and platinum sheet electrode as the reference electrode, use an electrochemical workstation (CHI660D) to react at a constant voltage of -1.3V at 25°C for 5 minutes. Deposit a layer of FeNi 3 electrocatalyst, and then scrape off the powder on the surface of the copper foil to obtain a dendrite FeNi 3 Electrocatalyst powder.

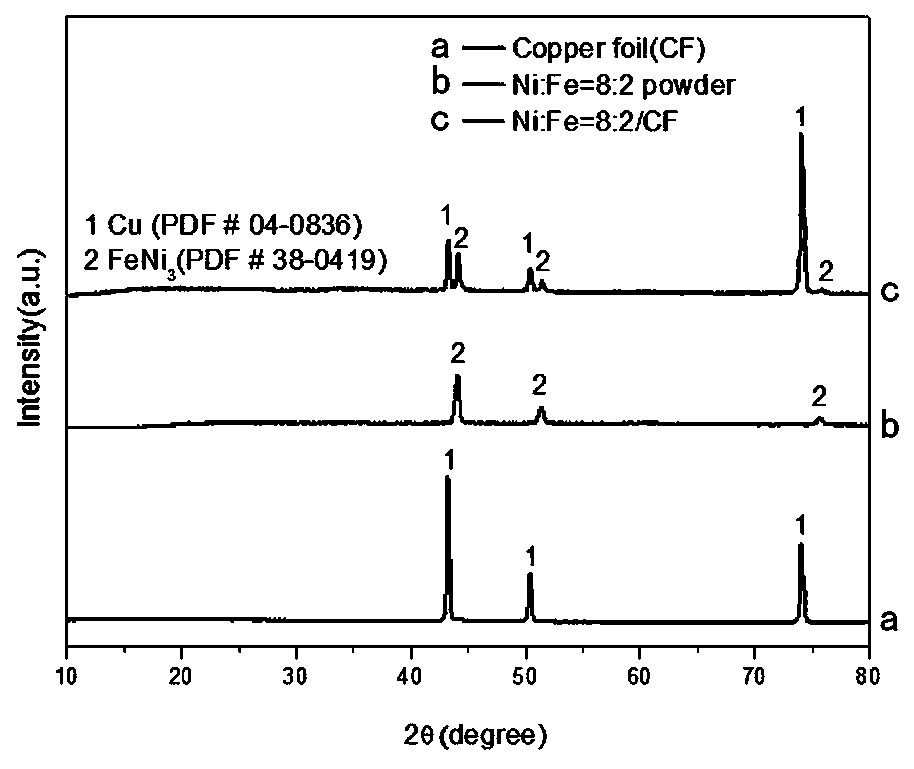

[0037] Such as figure 1 As shown, it is shown that the dendrite morphology FeNi prepared in Example 1 3 The XRD comparison diagram between the phase electrocatalyst powder, the electrodeposition composite catalytic electrode (powder + copper foil) and the copper foil support, it is obvious that the catalyst is displ...

Embodiment 2

[0041] Prepare a mixed aqueous solution of 0.03 mol / L nickel sulfate, 0.02 mol / L ferrous sulfate and 0.2 mol / L sodium sulfate as an electrodeposition solution; wash the copper foil with absolute ethanol and deionized water as an electrodeposition carrier. Using copper foil as the working electrode, Ag / AgCl electrode as the counter electrode, and platinum sheet electrode as the reference electrode, use an electrochemical workstation (CHI660D) to react at a constant voltage of -1.2V at 25°C for 5 minutes. Deposit a layer of FeNi 3 electrocatalyst, and then scrape off the powder on the surface of the copper foil to obtain a dendrite FeNi 3 Electrocatalyst powder.

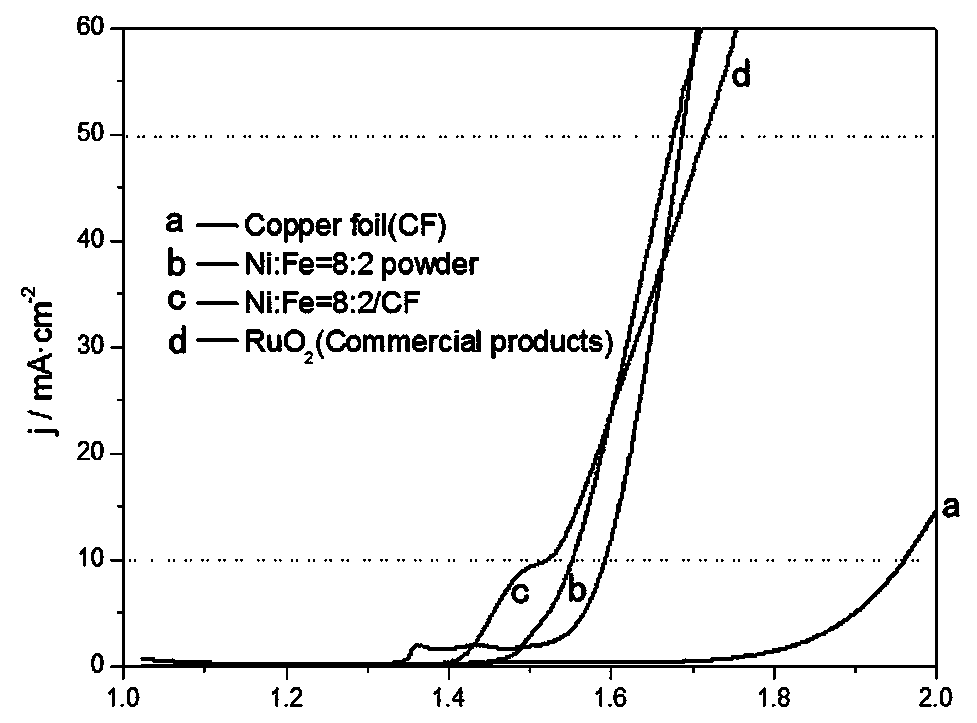

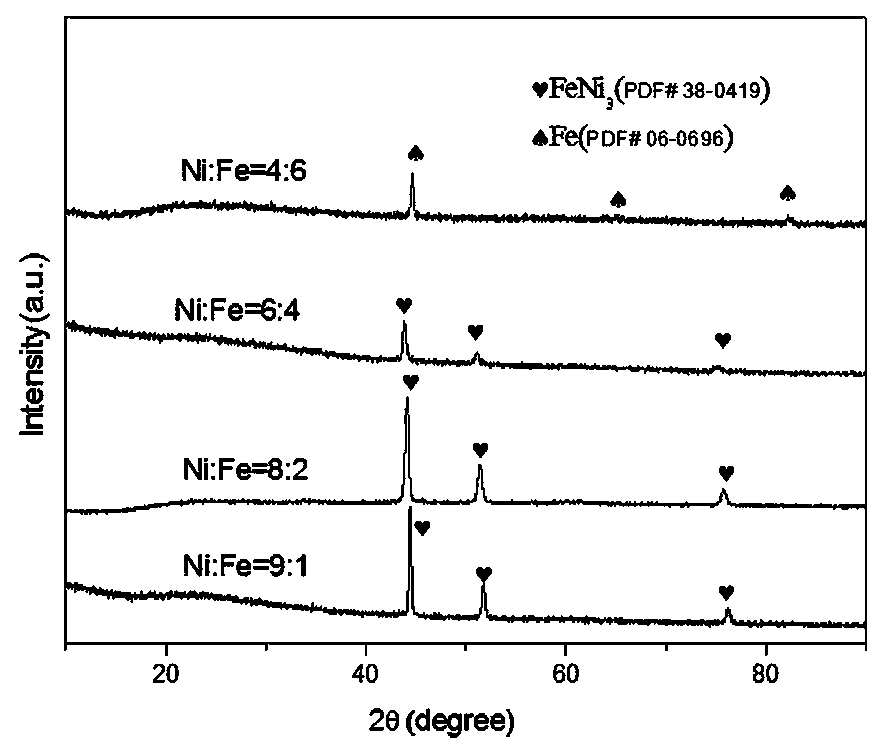

[0042] Such as image 3 Shown are the XRD comparison charts between the powder electrocatalysts prepared in Examples 1, 2, 3, and 4. Obviously, the catalyst powder that embodiment 2 prepares is identified as FeNi 3 phase; such as Figure 4 Shown is the comparison diagram of the LSV polarization curves between the ...

Embodiment 3

[0044] Prepare a mixed aqueous solution of 0.045 mol / L nickel sulfate, 0.005 mol / L ferrous sulfate and 0.3 mol / L sodium sulfate as an electrodeposition solution; wash the copper foil with absolute ethanol and deionized water as an electrodeposition carrier. Using copper foil as the working electrode, Ag / AgCl electrode as the counter electrode, and platinum sheet electrode as the reference electrode, use an electrochemical workstation (CHI660D) to react at a constant voltage of -1.3V at 25°C for 5 minutes. Deposit a layer of FeNi 3 electrocatalyst, and then scrape off the powder on the surface of the copper foil to obtain a dendrite FeNi 3 Electrocatalyst powder.

[0045] Such as image 3 Shown, the catalyst powder that embodiment 3 prepares is identified as FeNi 3 Mutually. Such as Figure 4 Shown, the FeNi that embodiment 3 prepares 3 The catalyst powder also exhibits good oxygen evolution performance under alkaline conditions (1 mol / L sodium hydroxide, pH = 14), when j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com