A kind of 310s stainless steel preparation method and 310s stainless steel

A technology of stainless steel and ladle, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of difficult production of 310S stainless steel, difficulty in meeting steel grade requirements, and longitudinal cracks in billets, so as to reduce the occurrence of longitudinal cracks and improve surface quality , The effect of homogenization of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples.

[0040] A 310S stainless steel, in terms of mass percentage, the 310S stainless steel includes the following components: C: 0.03-0.06; Si: 0.40-0.70; Mn: 1.30-1.60; P≤0.025; S≤0.0010; Cr: 25.30-25.90 ; Ni: 19.00~19.80; Mo: 0~0.5; N: 0.02~0.05; Cu: 0~0.5; Al: 0~0.1200; Cr is formed on the surface during isothermal oxidation 2 o 3 Protective oxide film, and no internal oxidation; at the same time, increasing the nickel content can improve the adhesion of the oxide film, reduce peeling, and its high temperature oxidation resistance is greatly improved. The preparation method of the 310S stainless steel includes smelting→continuous casting→hot rolling→annealing and pickling;

[0041] Wherein the smelting steps include:

[0042] A1) EAF (Electric Furnace) melts alloys and scrap steel, the temperature reaches 1550°C, and slag is removed after tapping;

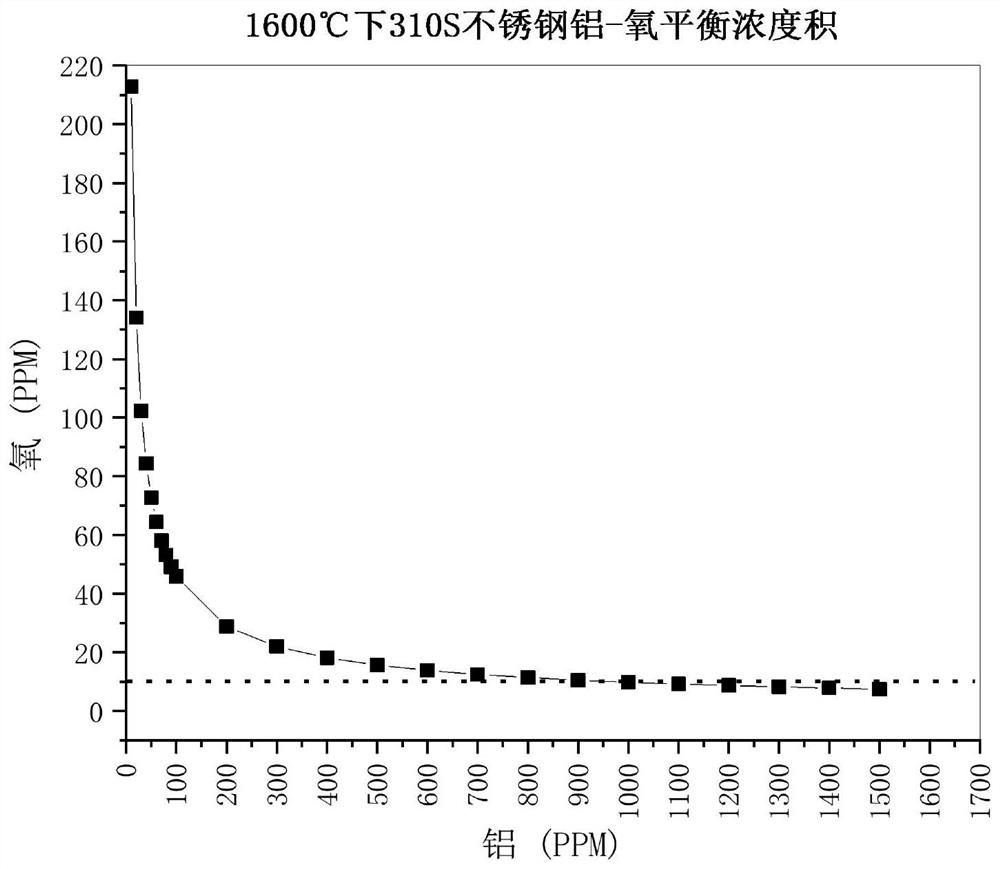

[0043] A2) AOD (Argon Oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com