Mine well mouth anti-freezing air heating device based on methyl alcohol nano catalytic oxidation

An air heating device and nano-catalysis technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of affecting the air flow and exhaust in the well, high labor operating costs, and complicated boiler operation. The effect of solving energy loss and construction costs, improving enterprise economic benefits and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

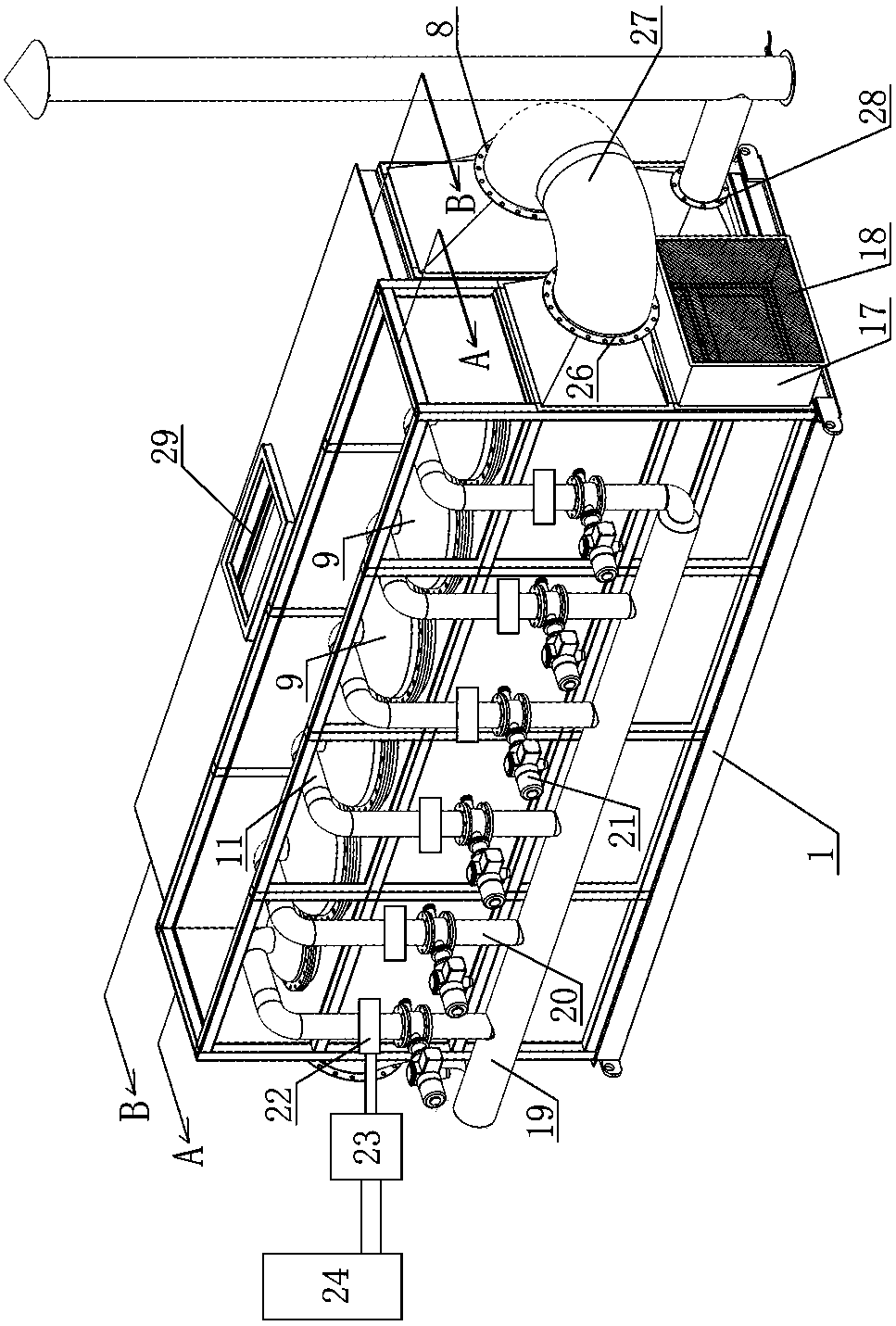

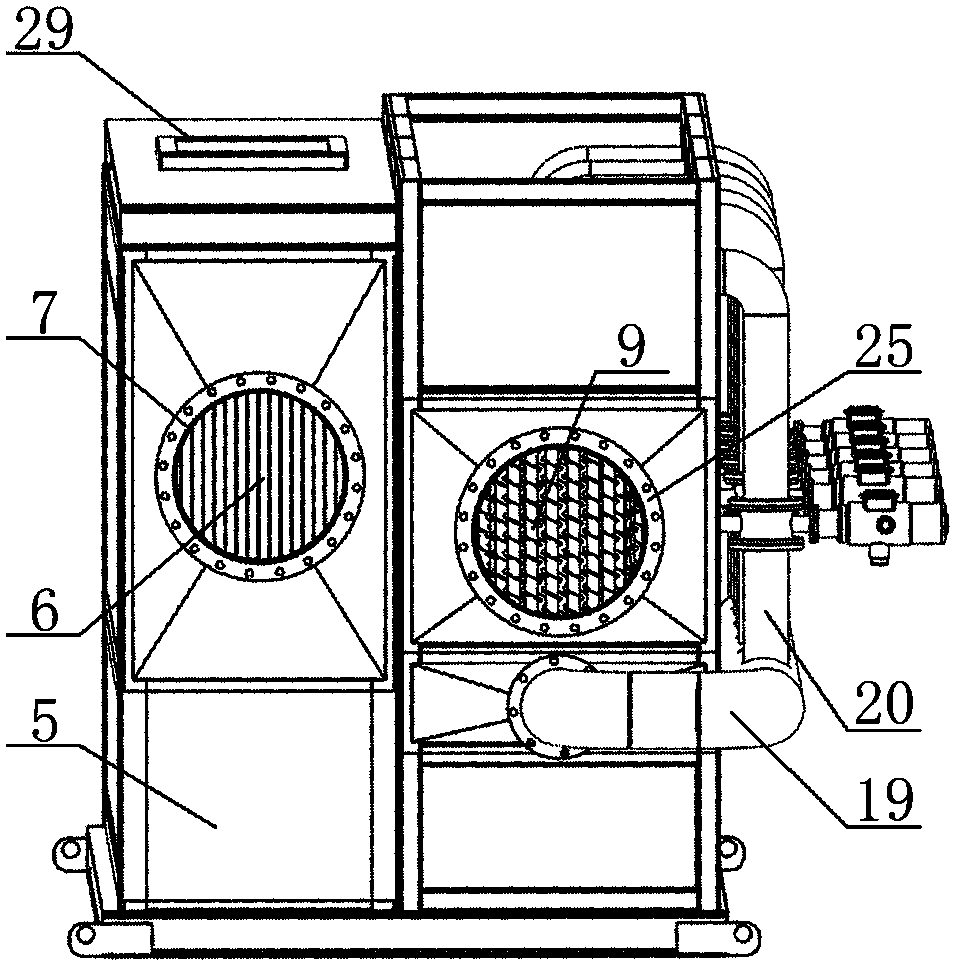

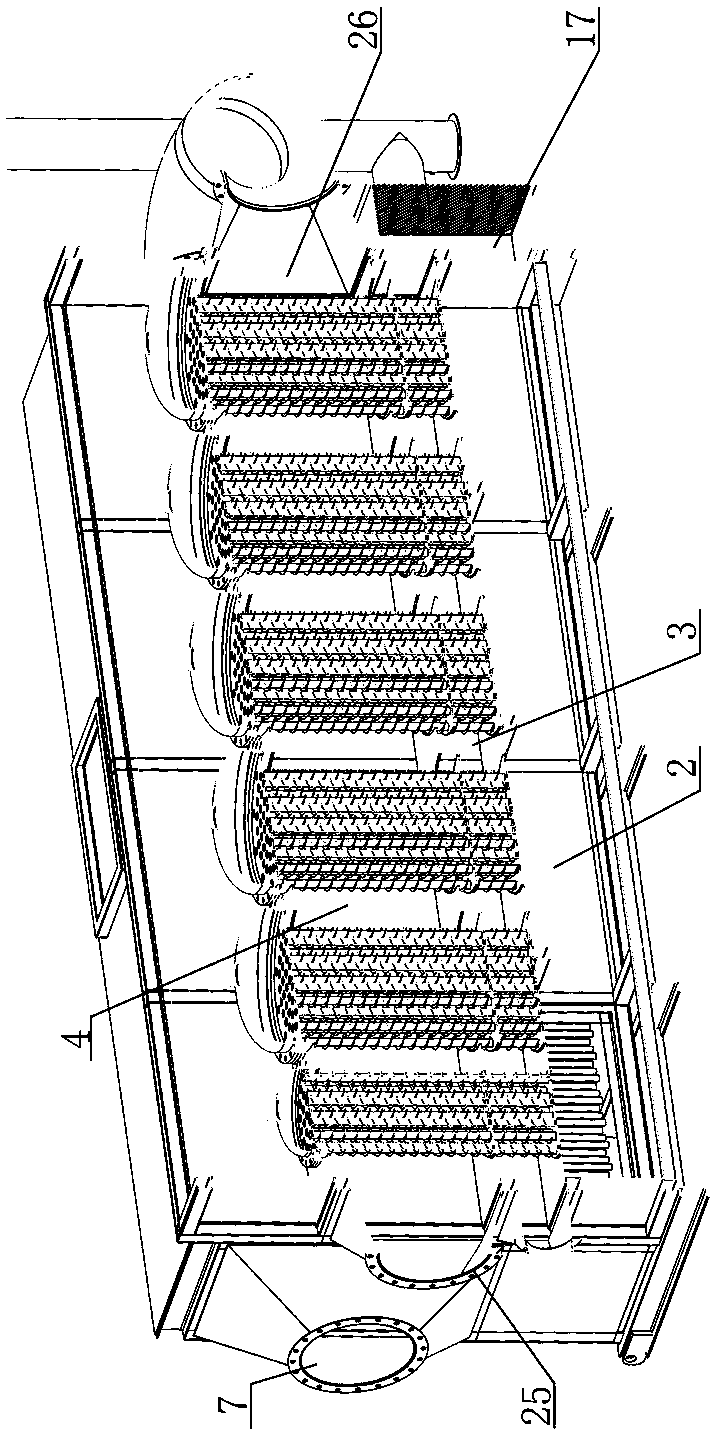

[0027] Such as Figure 1 to Figure 5 As shown, the present invention is based on methanol nano catalytic oxidation mine wellhead antifreeze air heating device, including a reaction device and a heating device arranged on the installation base 1, the reaction device and the heating device are arranged side by side, and the reaction device is composed of a plurality of steel plates A multi-chamber box, the inside of the reaction device is provided with a reaction bed waste heat chamber 2, a fresh air exchange chamber 3, and an initial air heat exchange chamber 4 in sequence from bottom to top, and an evaporation heat exchange chamber 5 is arranged inside the heating device. A plurality of exchanger heat pipes 6 are vertically arranged in the evaporation heat exchange chamber 5, a hot air outlet 7 is arranged at one end of the heating device, and a hot air inlet 8 is arranged at the other end of the heating device;

[0028] The initial air heat exchange chamber 4 of the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com