H-molybdenum trioxide/bis-metal sulfide composite material, preparation method and application

A metal sulfide and molybdenum trioxide technology, applied in chemical instruments and methods, chemical/physical processes, special compound water treatment, etc., can solve the problems of no catalytic activity, low atomic ratio, poor conductivity, etc., and achieve low cost , increase the atomic ratio, improve the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

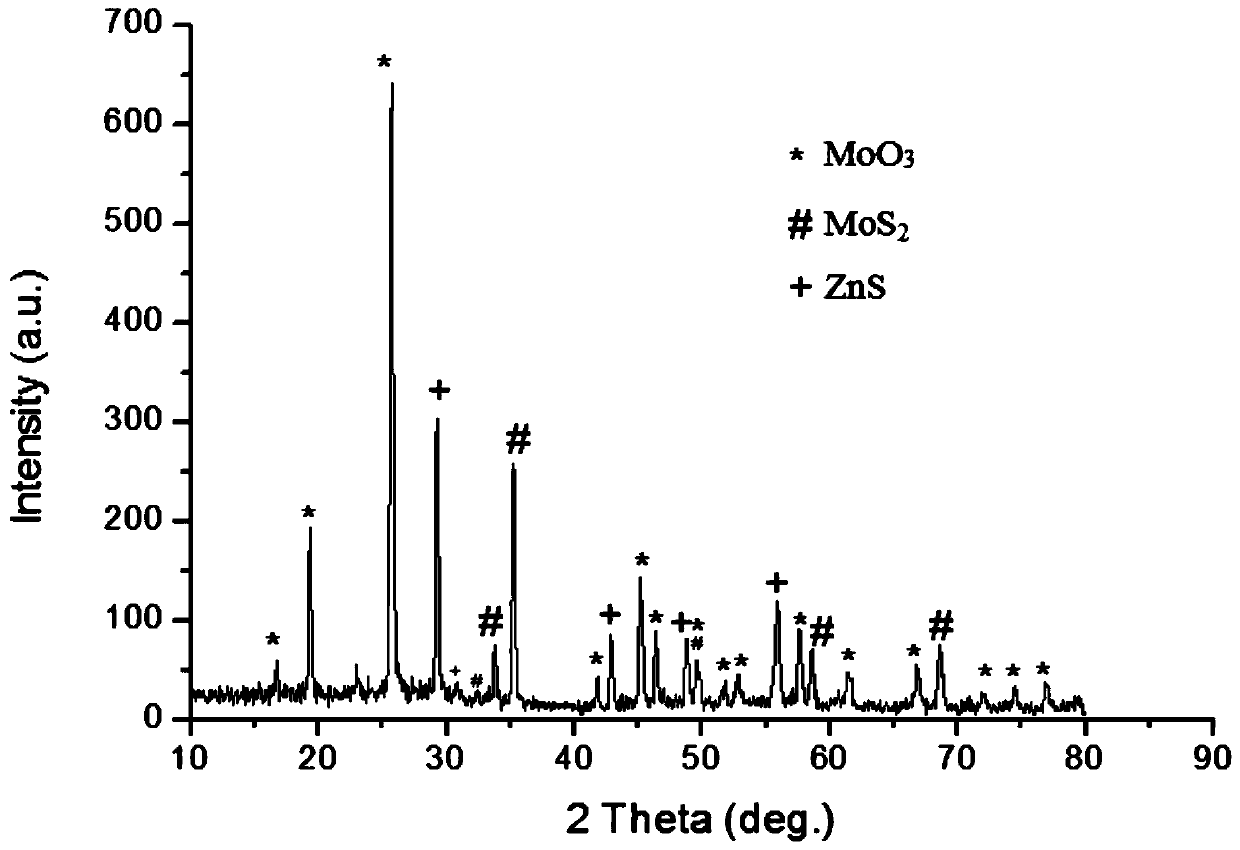

[0041] A preparation method of h-molybdenum trioxide / bimetallic sulfide composite material, comprising the following steps:

[0042] S1. Add 1.7g of sodium molybdate dihydrate to 195mL of water, ultrasonically dissolve, then add 5mL of concentrated nitric acid dropwise, stir and react for 1h at 30°C, then put the solution into the reaction kettle, and put the solution under the condition of 90°C , carry out hydrothermal reaction for 1 h, cool, filter, wash the precipitate twice with water and ethanol respectively, and dry to obtain h-MoO 3 ;

[0043]S2, 1g h-MoO 3 Add it to 40mL zinc nitrate solution with a concentration of 30.76mmol / L, carry out adsorption reaction at 25°C for 2 hours, filter, wash the precipitate, and dry it to obtain the initial product;

[0044] S3, the initial product is placed in the plasma exchange, and the gas flow rate is 25mL / min, and the volume ratio is 1:9 H 2 The mixed gas of S and argon for 15 minutes, after removing the air in the pipeline, c...

Embodiment 2

[0052] In the present embodiment, except that the zinc nitrate solution that concentration is 30.76mmol / L is replaced with concentration is that 33.90mmol / L nickel nitrate solution, all the other are identical with embodiment 1.

[0053] The h-molybdenum trioxide / bimetallic sulfide composite material obtained in this example is h-MoO 3 / 2H-MoS 2 -NiS material.

Embodiment 3

[0055] In this example, except that the zinc nitrate solution with a concentration of 30.76mmol / L was replaced with a copper sulfate solution with a concentration of 26.23mmol / L, the rest were the same as in Example 1.

[0056] The h-molybdenum trioxide / bimetallic sulfide composite material obtained in this example is h-MoO 3 / 2H-MoS 2 -CuS material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com