Method for preparing clenbuterol hydrochloride molecularly imprinted polymer microspheres

A technology of clenbuterol hydrochloride and molecular imprinting, which is applied in the field of preparation of clenbuterol hydrochloride molecularly imprinted polymer microspheres, can solve the problem of reducing the amount of organic surfactant used, complex preparation methods, and clenbuterol hydrochloride molecular imprinting technology. Issues such as low yield of imprinted polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

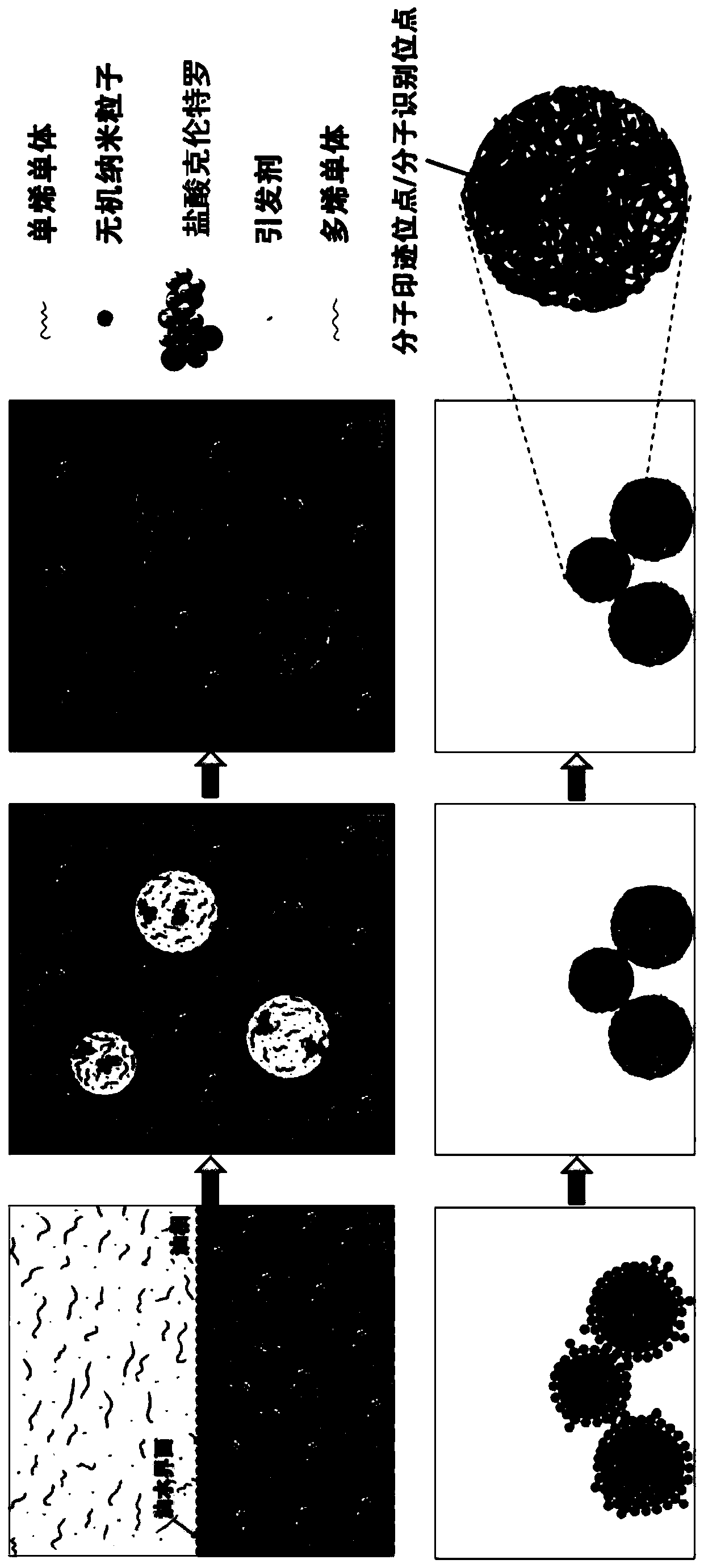

[0070] see figure 1 , the preparation method of molecularly imprinted polymer microspheres in this example is as follows:

[0071] 1) Add 0.12mL methacrylic acid (analytical grade), 6mL (0.3% by volume) polyethylene glycol octyl phenyl ether (analytical grade) to a stoppered glass vial, 20mg Aerosil 200nm silica nanoparticles (purity is 99%), 1.88mL ethylene glycol dimethacrylate (analytical pure), 10mg clenbuterol hydrochloride (analytical pure), 0.2mL toluene (analytical pure), 10mg azobisisobutyronitrile (analytical pure) Pure), the mixture was ultrasonically homogenized for 10 min, and shaken vigorously by hand for 6 min to obtain a uniform emulsion.

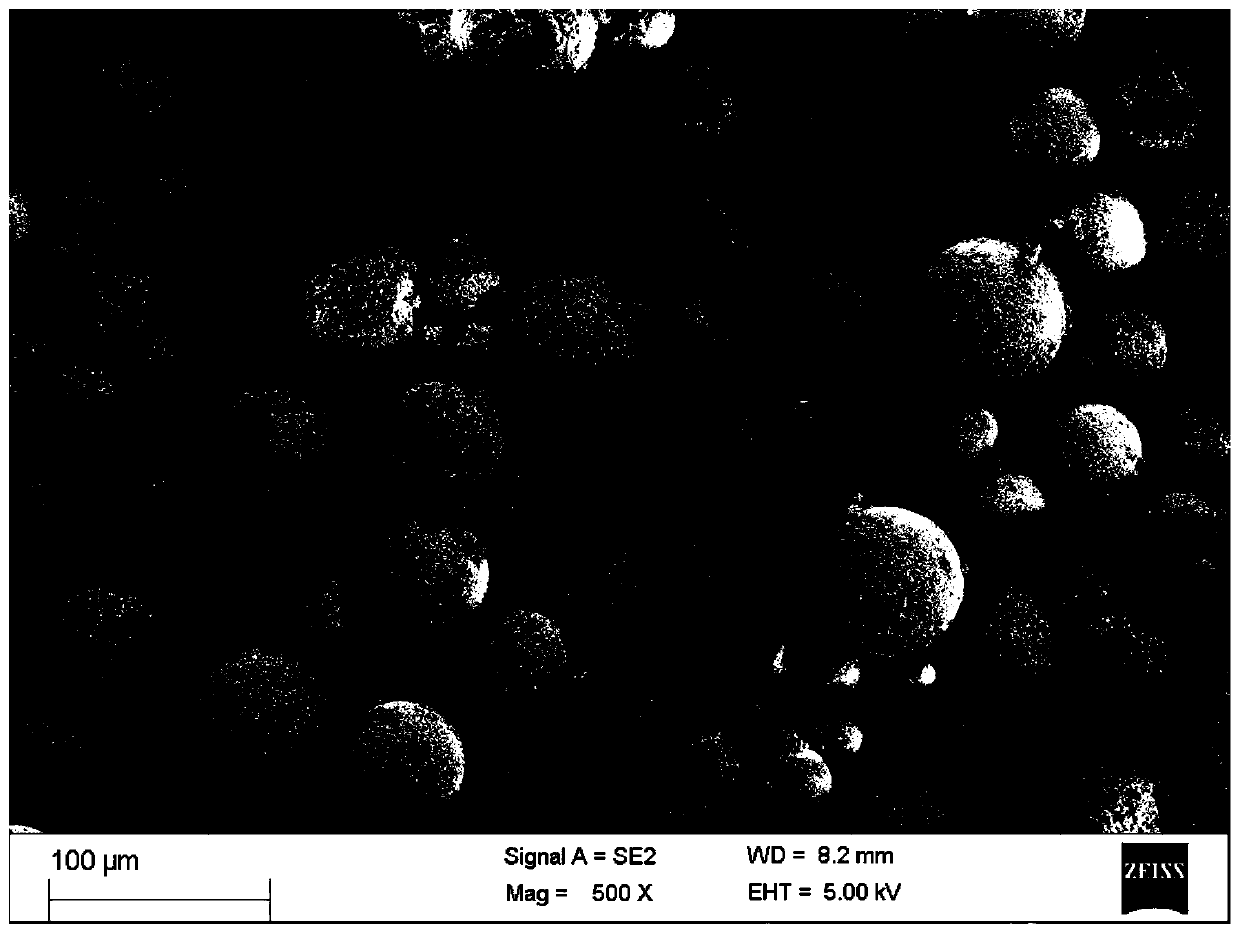

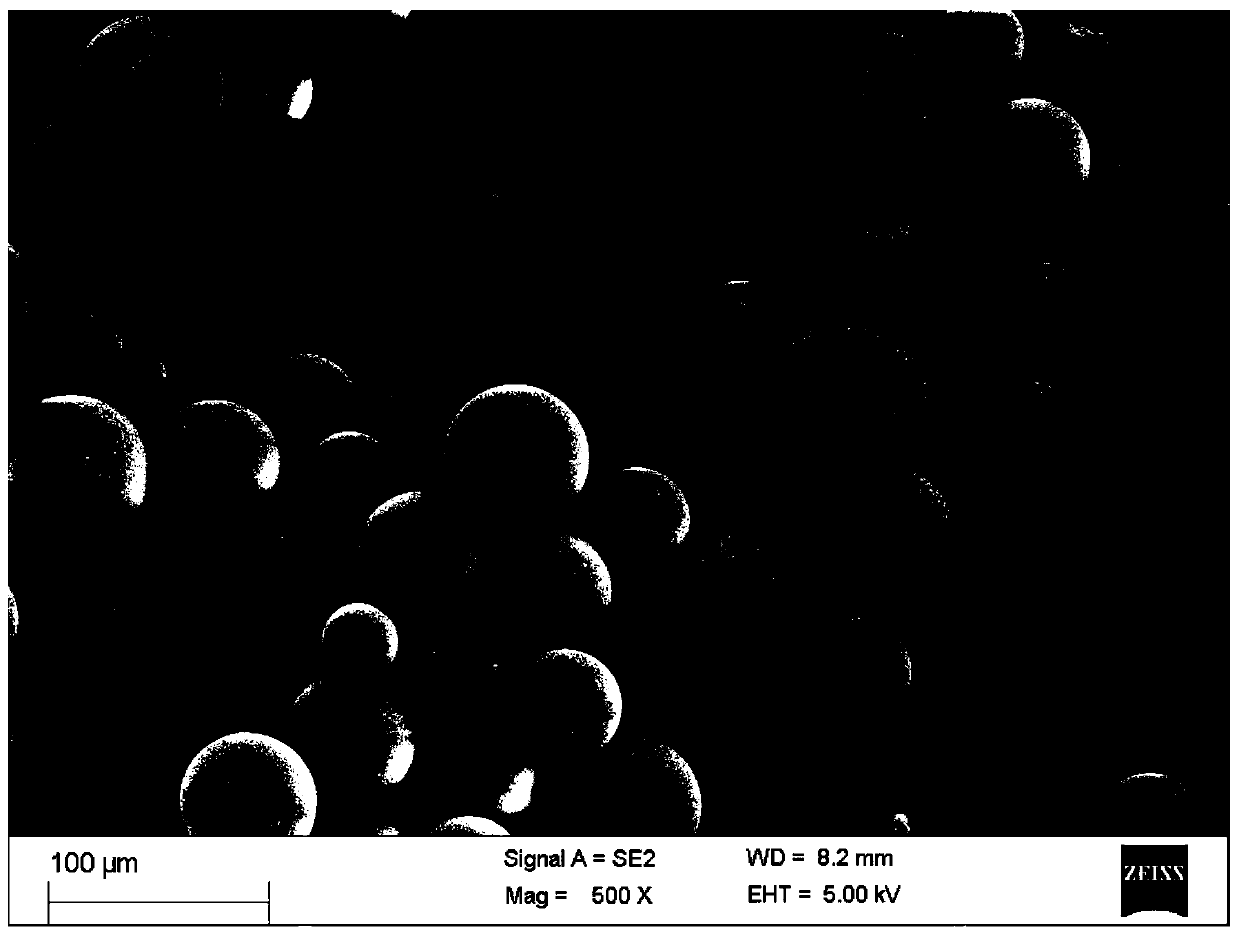

[0072] 2) Free radical polymerization: The emulsion was reacted in a water bath at 70°C for 12 hours to allow free radical polymerization of methacrylic acid and ethylene glycol dimethacrylate under the action of the initiator azobisisobutyronitrile to obtain For the sinking microspheres, wash the microspheres repeatedly w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com