Permanent antibacterial polyether sulfone membrane material and preparation method thereof

A technology of polyethersulfone membrane and polyethersulfone, which is applied in the field of polyethersulfone membrane material and its preparation, can solve the problems of unsatisfactory polymer grafting conditions, inhomogeneity of material properties, and low radiation energy, and achieve excellent antibacterial and hydrophilic properties, good electrochemical and thermal stability, and simple industrial preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

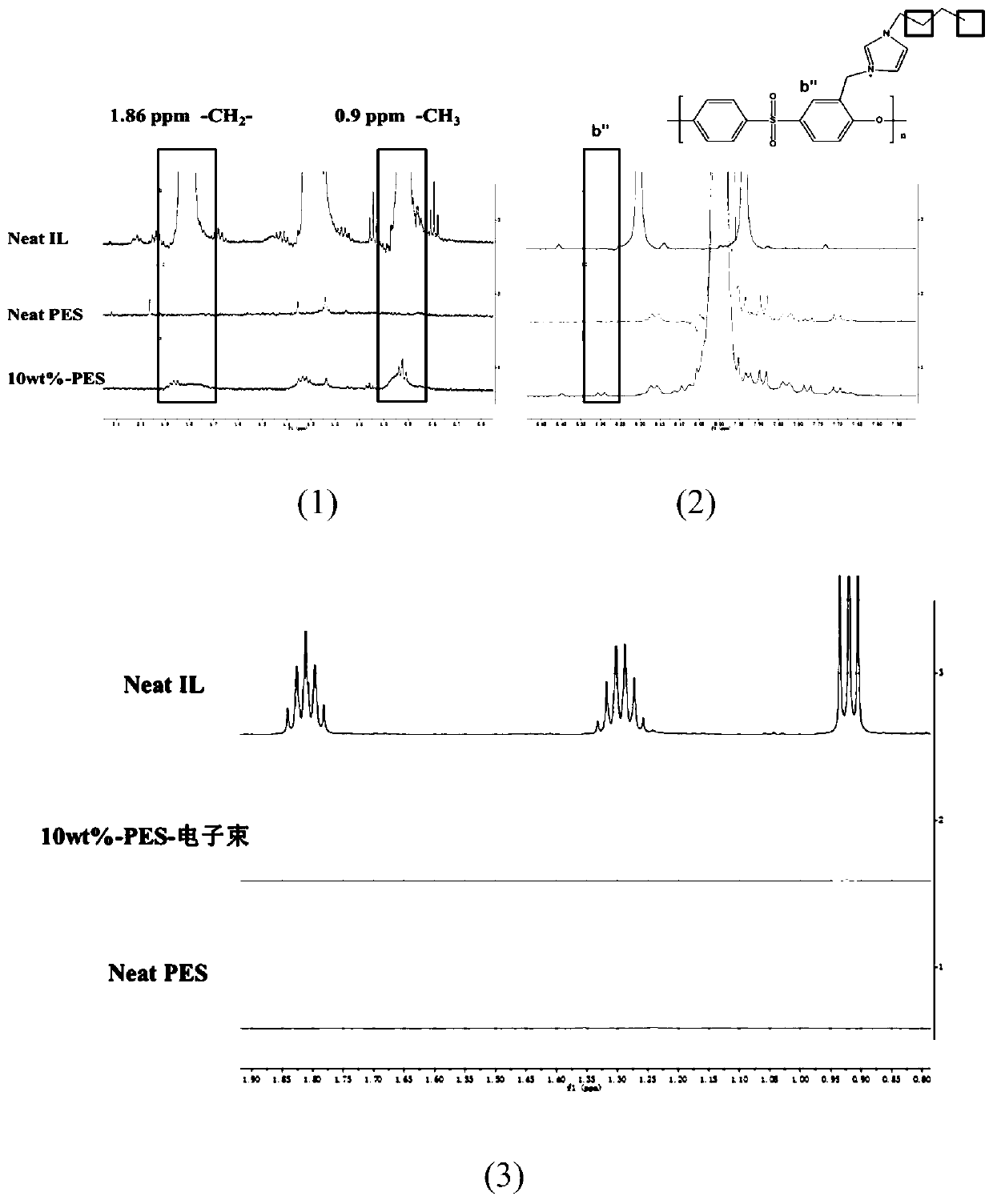

Method used

Image

Examples

Embodiment 1

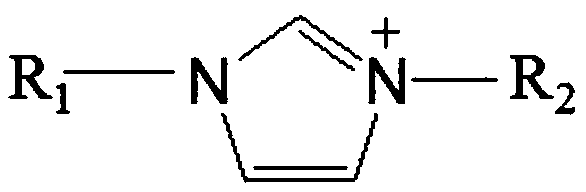

[0049] Step (1) First, 9.8g of PES and 0.2g of 1-vinyl-3-butylimidazolium tetrafluoroborate were added to the reaction kettle at a temperature of 60°C, and the solution was blended for 6h; then, the solution was cooled to At room temperature, it was poured into a PTFE mold for film laying, and the obtained film was volatilized with solvent and vacuum-dried for 24 hours to finally obtain a blended film of grafted ionic liquid. Recorded as 2wt%-PES modified film.

[0050] Step (2) Put the above-mentioned 2wt%-PES modified film in a polyethylene ziplock bag. In Co-γ irradiation, irradiation at room temperature was carried out at a dose of 30 kGy.

[0051] Step (3) directly press-molding the grafted blend obtained by the above-mentioned irradiation to obtain a PES modified membrane, the molding temperature is 250° C., the pressure is 10 MPa, the pressure is maintained for 3 minutes, and the thickness is 300 microns.

Embodiment 2

[0053] Step (1) First, 9.6g of PES and 0.4g of 1-vinyl-3-butylimidazolium tetrafluoroborate were added to the reaction kettle at a temperature of 60°C, and the solution was blended for 6h; then, the solution was cooled to At room temperature, it was poured into a PTFE mold for film laying, and the obtained film was volatilized with solvent and vacuum-dried for 24 hours to finally obtain a blended film of grafted ionic liquid. Recorded as 4wt%-PES modified film.

[0054] Step (2) Put the above-mentioned 4wt%-PES modified film in a polyethylene ziplock bag. In Co-γ irradiation, irradiation at room temperature was carried out at a dose of 30 kGy.

[0055] Step (3) directly press-molding the grafted blend obtained by the above-mentioned irradiation to obtain a PES modified membrane, the molding temperature is 250° C., the pressure is 10 MPa, the pressure is maintained for 3 minutes, and the thickness is 300 microns.

Embodiment 3

[0057] Step (1) First, 9.4g of PES and 0.6g of 1-vinyl-3-butylimidazolium tetrafluoroborate were added to the reaction kettle at a temperature of 60°C, and the solution was blended for 6h; then, the solution was cooled to At room temperature, it was poured into a PTFE mold for film laying, and the obtained film was volatilized with solvent and vacuum-dried for 24 hours to finally obtain a blended film of grafted ionic liquid. Recorded as 6wt%-PES modified film.

[0058] Step (2) Put the above-mentioned 6wt%-PES modified film in a polyethylene ziplock bag. In Co-γ irradiation, irradiation at room temperature was carried out at a dose of 30 kGy.

[0059] Step (3) directly press-molding the grafted blend obtained by the above-mentioned irradiation to obtain a PES modified membrane, the molding temperature is 250° C., the pressure is 10 MPa, the pressure is maintained for 3 minutes, and the thickness is 300 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com