Superstrong magnetic coating and preparation method thereof

A magnetic coating and super technology, applied in the field of coatings, can solve the problems of easy demagnetization, limited attraction, easy magnetization, etc., and achieve the effects of improved wear resistance and corrosion resistance, increased glass transition temperature, and increased thermal deformation temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

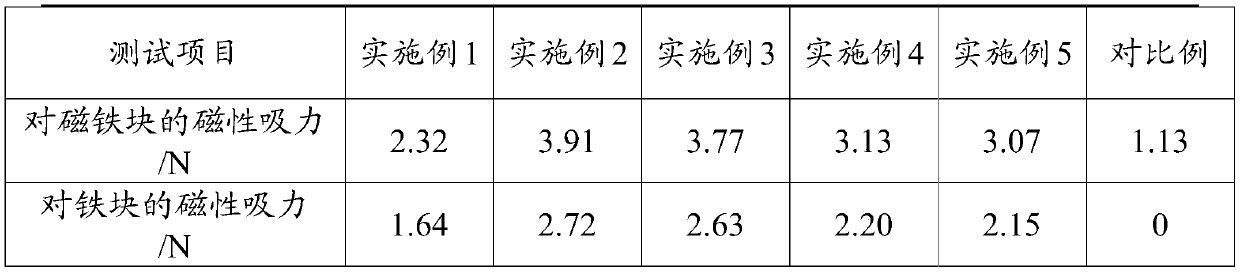

Examples

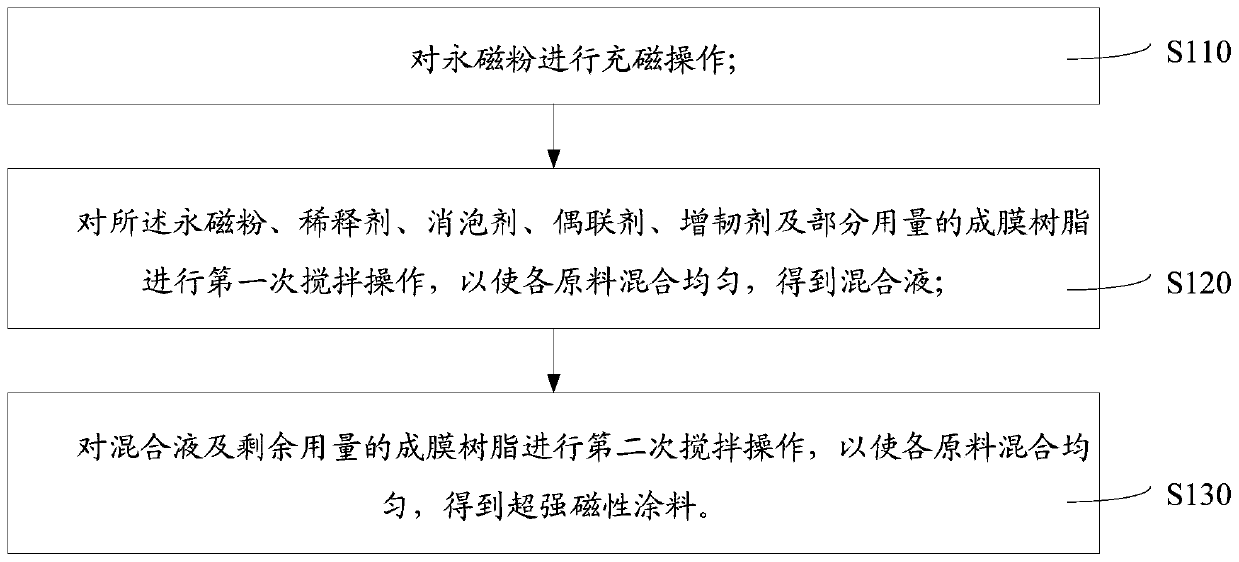

Embodiment approach

[0030] In order to better illustrate the above-mentioned super-magnetic paint, to better understand the concept of the above-mentioned super-magnetic paint. In one embodiment, a super-strong magnetic coating includes the following raw materials in parts by weight: 30-50 parts of film-forming resin, 50-450 parts of permanent magnetic powder, 30-50 parts of diluent, 1-3 parts of defoamer, 3-5 parts of joint agent and 3-10 parts of toughening agent.

[0031] It should be noted that permanent magnetic powder is selected as the magnetic source in this super-strong magnetic coating. After being added to this coating, the permanent magnetic powder attracts each other, thereby locking the film-forming resin and greatly increasing the magnetic powder content. The highest magnetic powder content can account for the solid content of the coating. The permanent magnetic powder itself is a hard magnetic material, which is not easy to demagnetize after magnetization and can retain magnetism ...

Embodiment 1

[0052] S111, performing a magnetization operation on the permanent magnet powder, so as to enhance the magnetism of the permanent magnet powder.

[0053] S121, mix 15 parts of epoxy resin, 50 parts of NdFeB permanent magnet powder, 30 parts of acetone, 1 part of alcohol defoamer, 3 parts of silane coupling agent and 3 parts of carboxymethyl cellulose, add to high-speed shear In the machine, it was sealed and stirred at a speed of 1500 rpm for 6 hours to obtain a mixed solution.

[0054] S131, mixing 15 parts of epoxy resin with the mixed solution, adding it into a high-speed shearing machine, and sealing and stirring at a speed of 3000 rpm for 6 hours to obtain a super-strong magnetic coating.

Embodiment 2

[0056] S112, performing a magnetization operation on the permanent magnet powder, so as to enhance the magnetism of the permanent magnet powder.

[0057] S122, mix 25 parts of polyurethane resin, 450 parts of samarium cobalt permanent magnet powder, 50 parts of ethanol, 3 parts of phosphoric acid defoamer, 5 parts of titanate coupling agent and 10 parts of hydroxymethyl cellulose, and add to high-speed shear Inside the machine, it was sealed and stirred at a speed of 2000 rpm for 2 hours to obtain a mixed solution.

[0058] S132, mixing 25 parts of epoxy resin with the mixed liquid, adding to a high-speed shearing machine, sealing and stirring at a speed of 4000 rpm for 2 hours to obtain a super-strong magnetic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com