Stratum-adsorption-resistant thick oil viscosity-reducing oil-displacing agent and applications thereof

An oil-displacing agent, a technology for heavy oil, applied in drilling compositions, chemical instruments and methods, organic chemistry, etc., can solve the problems of poor salt resistance, intolerant formation adsorption, and limited increase in recovery rate, etc. Achieve the effects of strong salt tolerance, enhanced oil recovery, and high oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1.1 Example 1: Preparation of heavy oil viscosity reducing oil displacement agent sample 1

[0042] Take 10% sodium dodecylphenol polyoxyethylene ether (9EO)-3,5-dimethylene-dodecylbenzene sulfonate and 15% sodium dodecylphenol polyoxyethylene ether (3EO) sulfonate , Take 10% of octylphenol polyoxyethylene ether (10EO), take 5% of lauric acid diethanolamide, take 20% of methanol, add water to 100%, mix and stir evenly, and obtain heavy oil viscosity reducing oil displacement agent sample 1.

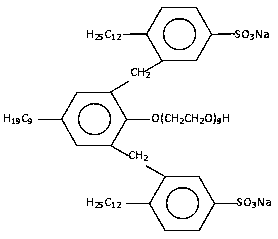

[0043] The structural formula of dodecylphenol polyoxyethylene ether (9EO)-3,5-dimethylene-dodecylbenzenesulfonate used in embodiment 1 is as follows:

[0044]

Embodiment 2

[0045] 1.2 Example 2: Preparation of heavy oil viscosity reducing oil displacement agent sample 2

[0046] Take 15% of nonylphenol polyoxyethylene ether (9EO)-3,5-dimethylene-dodecylbenzene sulfonate, 15% of sodium lauryl alcohol polyoxyethylene ether (4EO), and Take 10% nonylphenol polyoxyethylene ether (10EO), take 5% palmitic acid diethanolamide, take 20% ethanol, add water to 100%, mix and stir evenly, and obtain heavy oil viscosity reducing oil displacement agent sample 2.

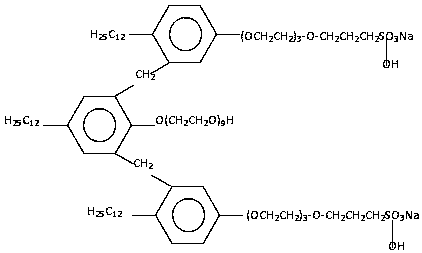

[0047] The nonylphenol polyoxyethylene ether (9EO)-3,5-dimethylene-dodecylbenzenesulfonate sodium used in Example 2 has the following structural formula:

[0048]

Embodiment 3

[0049] 1.3 Example 3: Preparation of heavy oil viscosity reducing oil displacement agent sample 3

[0050] Take dodecylphenol polyoxyethylene ether (9EO)-3,5-dimethylene-didodecylphenol polyoxyethylene ether (3EO) sodium hydroxypropanesulfonate 10%, take dodecyl alcohol polyoxyethylene Ether (4EO) sodium sulfonate 15%, take nonylphenol polyoxyethylene ether (5EO) hydroxypropyl sulfonate 10%, take stearic acid diethanolamide 5%, take isopropanol 20%, replenish water to 100 %, mixed and stirred evenly to obtain heavy oil viscosity reducing oil displacement agent sample 3.

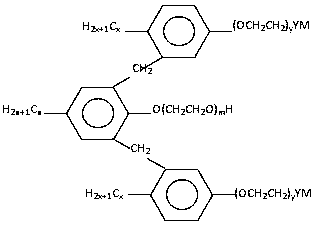

[0051] The structural formula of dodecylphenol polyoxyethylene ether (9EO)-3,5-dimethylene-didodecylphenol polyoxyethylene ether (3EO) sodium hydroxypropanesulfonate used in Example 3 is as follows:

[0052]

[0053] 2. Laboratory performance test

[0054] 2.1 Measurement of interfacial tension of heavy oil viscosity reducing oil displacement agent

[0055] The samples of Examples 1-3 were taken, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com