Antibacterial textile product containing tea fibers and preparation method thereof

A technology for antibacterial textiles and tea fibers, applied in the field of textiles, can solve the problems of large dimensional change rate and low content of tea polyphenols in fabrics containing tea fibers, and achieve good environmental compatibility and degradability, and biological enzyme desizing. Mild conditions and long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

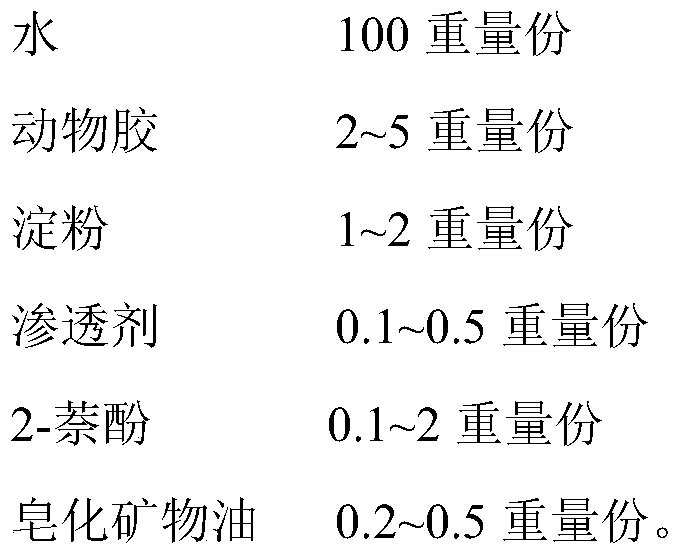

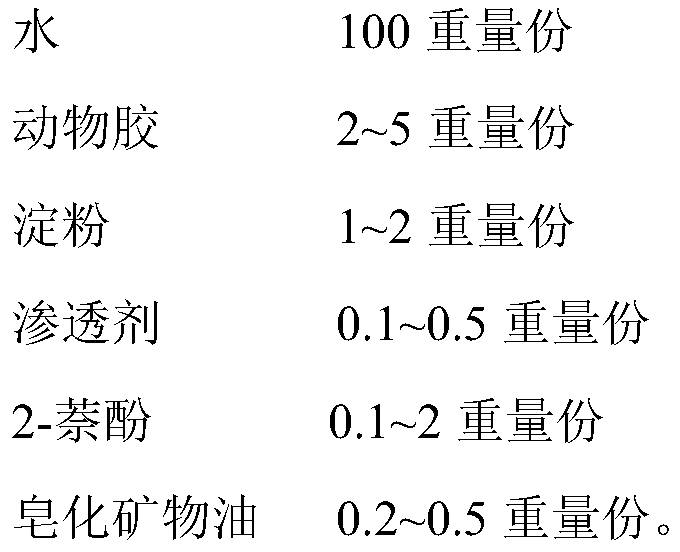

[0043] In the present embodiment, tea fiber accounts for 20% of the gray cloth fiber gross weight, and the usage amount of short tencel fiber is 80%; taking the total mass of tea fiber as a benchmark, the content of tea polyphenols in the tea fiber is 100mg / kg;

[0044] Both warp and weft yarns are 60S;

[0045] The linear density of the tea fiber is 6.70dtex;

[0046] Yarn sizing ratio: 100 parts by weight of water, 2 parts by weight of animal glue, 1 part by weight of starch, 0.1 part by weight of penetrant JRC, 0.1 part by weight of 2-naphthol, 0.2 part by weight of saponified mineral oil; the temperature of the size tank The temperature is 80°C, the slurry viscosity is 5MPa·s, the sizing rate is 8%, and the moisture regain rate is 8%.

[0047]The desizing solution contains: α-amylase 0.75g / L, trypsin 0.1g / L, penetrant JRC 0.1g / L, calcium chloride 0.25g / L. The temperature of the desizing enzyme solution is 60°C, the pH value is 7.5, the soaking time is 60min, the squeeze ...

Embodiment 2

[0051] In the present embodiment, tea fiber accounts for 20% of the total weight of gray cloth fibers, the usage amount of tencel staple fiber is 60%, and the usage amount of cotton staple fiber is 20%; based on the total mass of tea fiber, the tea fiber The content of tea polyphenols is 200mg / kg; the warp and weft yarn counts are both 40S.

[0052] The linear density of the tea fiber is 2.78dtex;

[0053] Yarn sizing slurry proportioning: 100 parts by weight of water, 5 parts by weight of animal glue, 2 parts by weight of starch, 0.4 part by weight of penetrant JRC, 0.5 part by weight of 2-naphthol, 0.5 part by weight of saponified mineral oil; the temperature of the size tank The temperature is 90°C, the slurry viscosity is 8MPa·s, the sizing rate is 10%, and the moisture regain rate is 10%.

[0054] The desizing solution contains: α-amylase 0.5g / L, trypsin 0.25g / L, penetrant JRC 0.2g / L, calcium chloride 0.4g / L. The temperature of the desizing enzyme solution is 40°C, the ...

Embodiment 3

[0058] In the present embodiment, tea fiber accounts for 30% of the total weight of gray cloth fibers, the usage amount of tencel staple fiber is 60%, and the usage amount of cotton staple fiber is 10%; based on the total mass of tea fiber, the tea fiber The content of polyphenols in Chinese tea is 300mg / kg;

[0059] The linear density of the tea fiber is 1.56dtex; the warp and weft yarn counts are both 32S.

[0060] Yarn sizing slurry proportioning: 100 parts by weight of water, 4 parts by weight of animal glue, 2 parts by weight of starch, 0.5 part by weight of penetrant JRC, 1 part by weight of 2-naphthol, 0.3 part by weight of saponified mineral oil; the temperature of the size tank The temperature is 85°C, the slurry viscosity is 20MPa·s, the sizing rate is 10%, and the moisture regain rate is 9%.

[0061] The desizing solution contains: α-amylase 0.2g / L, trypsin 0.6g / L, penetrant JRC 0.4g / L, calcium chloride 0.4g / L. The temperature of the desizing enzyme solution is 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com