High-calcium high-protein milk candy and making method thereof

A high-protein, toffee technology, used in confectionery, confectionery industry, food ingredients as a taste improver, etc., can solve the problems of hidden health risks and high sugar content, and achieve the effect of improving taste, good taste and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

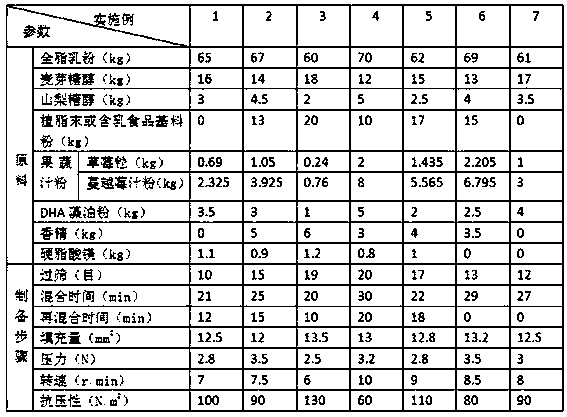

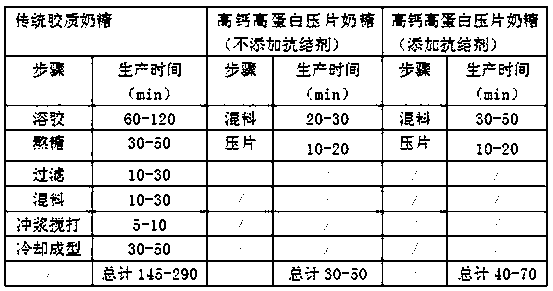

[0025] Example 1-7 High-calcium and high-protein toffee and its preparation method

[0026] Examples 1-7 are a high-calcium and high-protein toffee and its preparation method, and the composition of raw materials and parameters of preparation steps for making them are shown in Table 1.

[0027] Their preparation methods are carried out according to the following steps: sieve the sorbitol and strawberry grains in the raw material composition, mix with other raw material compositions, and then compress into tablets to obtain high-calcium and high-protein toffee, or sorbitol in the raw material composition The sugar alcohol and strawberry grains are sieved separately, mixed with other raw materials, added anti-caking agent magnesium stearate, mixed and pressed into tablets to obtain high-calcium and high-protein milk candy.

[0028] Table 1 Raw material components and preparation parameters of high-calcium and high-protein toffee in Examples 1-7

[0029]

[0030] The preparat...

Embodiment 8

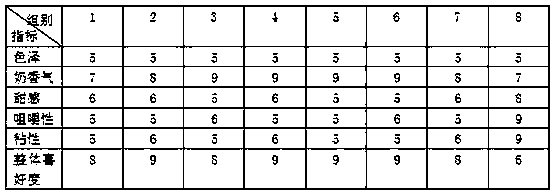

[0034] Example 8 Example 1-7 Taste Evaluation of High Calcium and High Protein Milk Candy

[0035] 50 testers were selected to evaluate the taste of the high-calcium and high-protein milk candies of Examples 1-7 as the test group 1-7 and the traditional milk candy as the control group 8, according to their color, milk aroma, and sweetness. , chewiness, stickiness and overall liking are scored, the color score is scored using a 5-point scoring method, and the milk aroma, sweetness, chewiness, and stickiness are scored using a 10-point intensity scale method (10→0 means extremely strong→not noticeable) , the overall liking degree adopts the 9-point pleasure scale method (9→1 means extremely like→extremely dislike), and then calculates the average value, and the results are shown in Table 3:

[0036] Table 3 Comparison of taste evaluation

[0037]

[0038] From the comparative data in Table 3, it can be seen that compared with the traditional toffee, the high-calcium and high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com