Zeolite molecular sieve-PVDF-chitosan composite ultrafiltration membrane and application thereof

A technology of zeolite molecular sieve and chitosan, applied in ultrafiltration, membrane, membrane technology, etc., can solve the problems of strong hydrophobicity, weak antifouling ability, low water flux of PVDF fiber membrane, etc., and achieve good hydrophilicity, Effects of low weight, promoting water flux performance and antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of zeolite molecular sieve-PVDF-chitosan composite ultrafiltration membrane, comprising the following steps:

[0025] (1) Mix 1.0g of dimethylacetamide and 3.6g of acetone to make a binary solvent (the weight ratio of the two is 1:3.6), stir in a glass bottle with a cover for 1h at a stirring speed of 200r / min, and then separate Add 0.015g of polyvinylpyrrolidone and 0.015g of nano-zeolite particles, stir evenly for 1h to obtain a mixed solution; add 1.5g of PVDF powder to the above solution and mix, stir in a water bath at 80°C until the powder is completely dissolved, put it into an ultrasonic instrument and continue to sonicate for 6h , to obtain the electrospinning precursor solution.

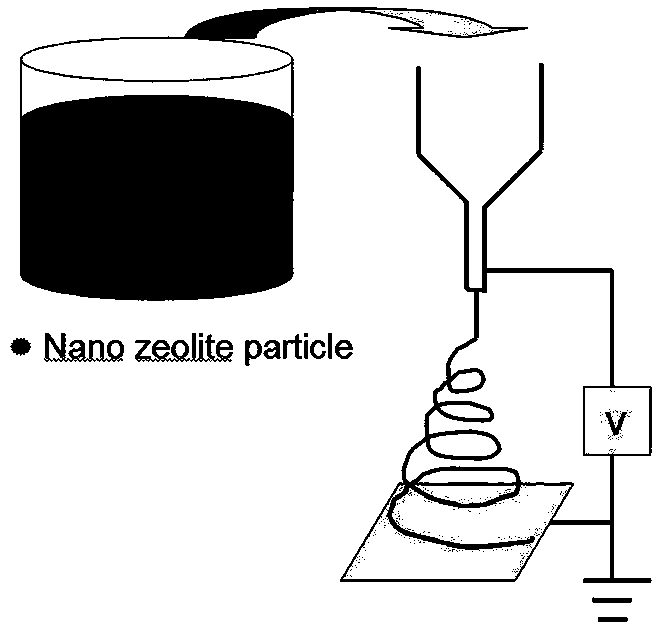

[0026] (2) Place the electrospinning precursor solution above under a high-voltage electrostatic field for electrospinning to obtain nanocomposite fibers with 1.0% nanometer zeolite. Calculation method of nano zeolite content: m 纳米沸石 / m 溶质总质量 , the total mass ...

Embodiment 2

[0031] A preparation method of zeolite molecular sieve-PVDF-chitosan composite ultrafiltration membrane, comprising the following steps:

[0032] (1) Mix 1.0g of dimethylacetamide and 3.6g of acetone to make a binary solvent (the weight ratio of the two is 1:3.6), stir in a glass bottle with a cover for 1h at a stirring speed of 200r / min, and then separate Add 0.048g polyvinylpyrrolidone and 0.048g nano-zeolite particles, stir evenly for 1 hour to obtain a mixed solution; add 1.5g PVDF powder to the above solution and mix, stir in a water bath at 60°C until the powder is completely dissolved, put it into an ultrasonic instrument and continue to sonicate for 8 hours, Obtain electrospinning precursor solution.

[0033] (2) Place the electrospinning precursor solution above under a high-voltage electrostatic field for electrospinning to obtain nanocomposite fibers with 3.0% nanometer zeolite.

[0034] Put the homogeneously mixed electrospinning precursor solution prepared above ...

Embodiment 3

[0038] A preparation method of zeolite molecular sieve-PVDF-chitosan composite ultrafiltration membrane, comprising the following steps:

[0039](1) Mix 1.0g dimethylacetamide and 3.2g acetone to make a binary solvent (the weight ratio of the two is 1:3.2), stir in a glass bottle with a cover for 1h at a stirring speed of 350r / min, and then separate Add 0.083g of polyvinylpyrrolidone and 0.083g of nano-zeolite particles, stir for 1 hour to obtain a mixed solution; add 1.5g of PVDF powder to the above solution and mix, stir in a water bath at 50°C until the powder is completely dissolved, and put it into an ultrasonic instrument for continuous ultrasonication for 6 hours. Obtain electrospinning precursor solution.

[0040] (2) Place the electrospinning precursor solution above under a high-voltage electrostatic field for electrospinning to obtain nanocomposite fibers with 5.0% nanometer zeolite.

[0041] Put the homogeneously mixed electrospinning precursor solution prepared a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com